A method for preparing concrete

A technology for concrete and preparation devices, applied in clay preparation devices, chemical instruments and methods, sustainable waste treatment, etc., can solve the problems of insufficient concrete mixing, reduced screening efficiency, easy blocking of screens, etc. Quality and mixing efficiency, improve screening efficiency and quality, avoid the effect of honeycomb

Active Publication Date: 2022-05-31

湖南省云传供应链管理有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] 1. When the traditional screening device performs screening work, larger sand and gravel materials are easy to block the screen, which reduces the screening efficiency;

[0005] 2. Theoretically, in order to improve the mixing quality, the materials with low density should be put into the mixing first, and then the materials with high density should be put into the mixing step by step. However, in most cases, the order of feeding and the proportional relationship are ignored in order to improve the efficiency, which will easily cause the concrete to mix poorly. Adequate, poor homogeneity, honeycomb phenomenon

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0028] Below in conjunction with the accompanying drawings and embodiments, the technical solutions of the present invention are described in further detail.

[0030] Step S1, according to the mixing ratio, cement, water, admixture solution, externally mixed mixed material are weighed respectively.

[0032] Step S3, start the concrete preparation device to carry out the preparation of concrete.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

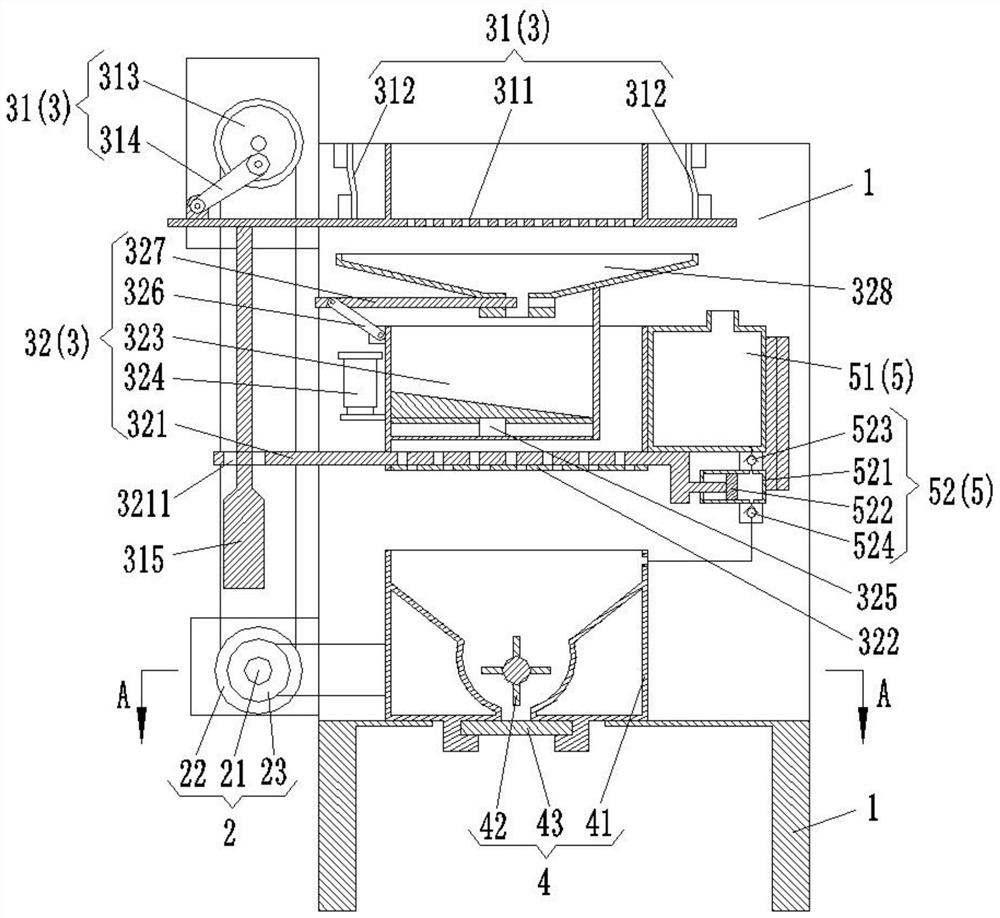

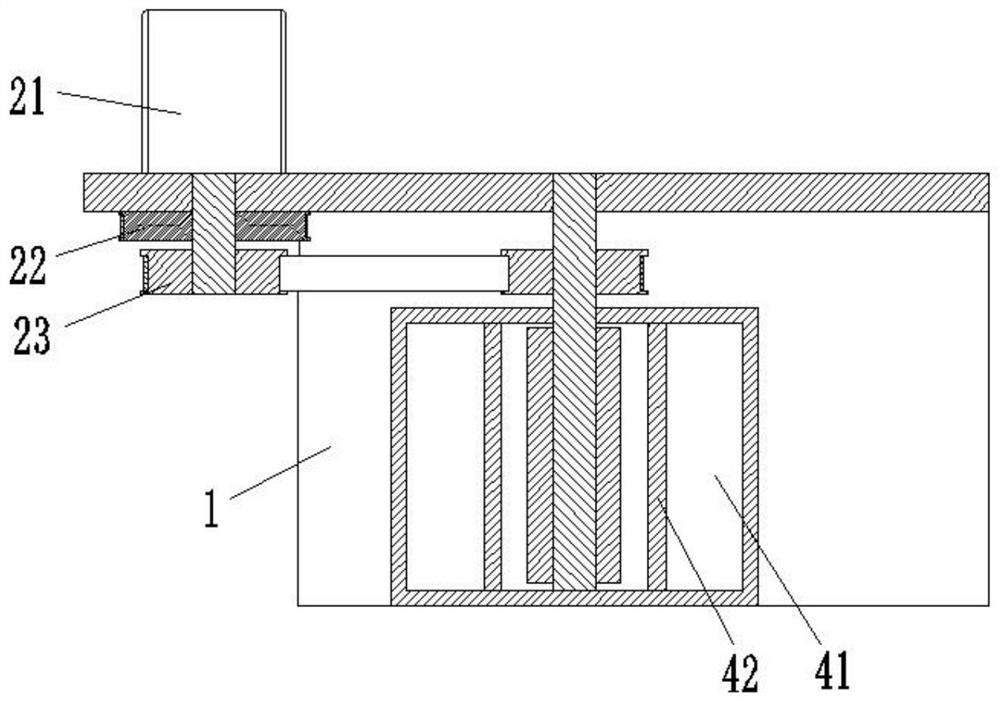

The invention belongs to the technical field of concrete preparation and discloses a concrete preparation method. In the concrete preparation method, the concrete preparation device used includes a driving mechanism, a screening mechanism, a stirring mechanism and a water supply mechanism fixed on the mounting frame; the driving mechanism is respectively connected with the screening mechanism, the stirring mechanism and the The water supply mechanism is connected, and drives the screening mechanism, the stirring mechanism and the water supply mechanism to work; the screening mechanism includes a first screening mechanism and a second screening mechanism, and the second screening mechanism Located between the first screening mechanism and the stirring mechanism, it is used to directly feed the stirring mechanism; the second screening mechanism is connected to the water supply mechanism, and performs synchronous feeding and Inject water. By adopting the concrete preparation method of the invention to carry out concrete preparation operation, the production quality of concrete can be improved.

Description

A kind of concrete preparation method technical field The invention belongs to concrete preparation technical field, be specifically related to a kind of concrete preparation method. Background technique Concrete usually refers to taking cement as the main cementitious material, and mixing it with water, sand, and stones, if necessary, mixing chemical external materials. Additives and mineral admixtures, and in accordance with scientific proportions, go through the processes of uniform stirring, compacting, curing and hardening. Production of obtained artificial stone. Concrete is rich in raw materials, low in price, low in production cost, and has good plasticity. It has the advantages of high strength, good durability, available steel reinforcement, corrosion resistance and long service life. However, there are following problems in the production process of existing concrete: 1, when traditional sieving device carries out sieving work, larger sand and gravel ma...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B28C5/14B28C5/08B28C7/12B07B1/28B07B1/46

CPCB28C5/148B28C5/0887B28C7/126B07B1/28B07B1/4609B07B1/46Y02W30/91

Inventor 秦克鲁袁广社陈存凤

Owner 湖南省云传供应链管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com