Yin-yang membrane dual-mode solvent-free composite production process

A production process, yin and yang film technology, applied in the direction of layered products, lamination devices, winding strips, etc., can solve problems such as low efficiency, and achieve the effect of improving composite efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

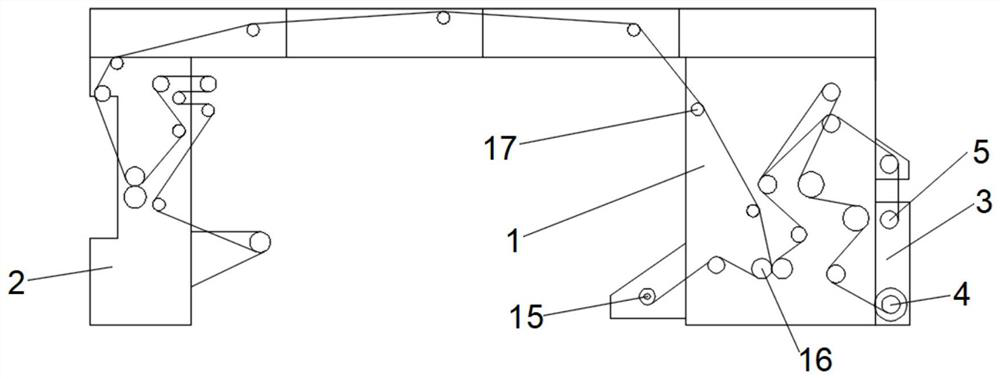

[0042] A dual-mode solvent-free composite production process of an anion-yang film, characterized in that it comprises the following steps:

[0043] A: Put the two kinds of base materials into the dual-mode composite mechanism of Yin-Yang film respectively, and set the relevant parameters;

[0044] B: Roll out a part of the two base materials from the base material roll, and load the unrolled parts on the cloth roll in order, and roll them into the compound unit through the cloth roll, and pass the compound material in the second frame through the conveying roll. into the composite unit and spread on top of the two substrates;

[0045] C: Coating the composite material and heating it to the composite unit to carry out the solvent-free composite production of the two-mode anion-yang film, and collect the finished composite film in the discharge direction of the composite unit.

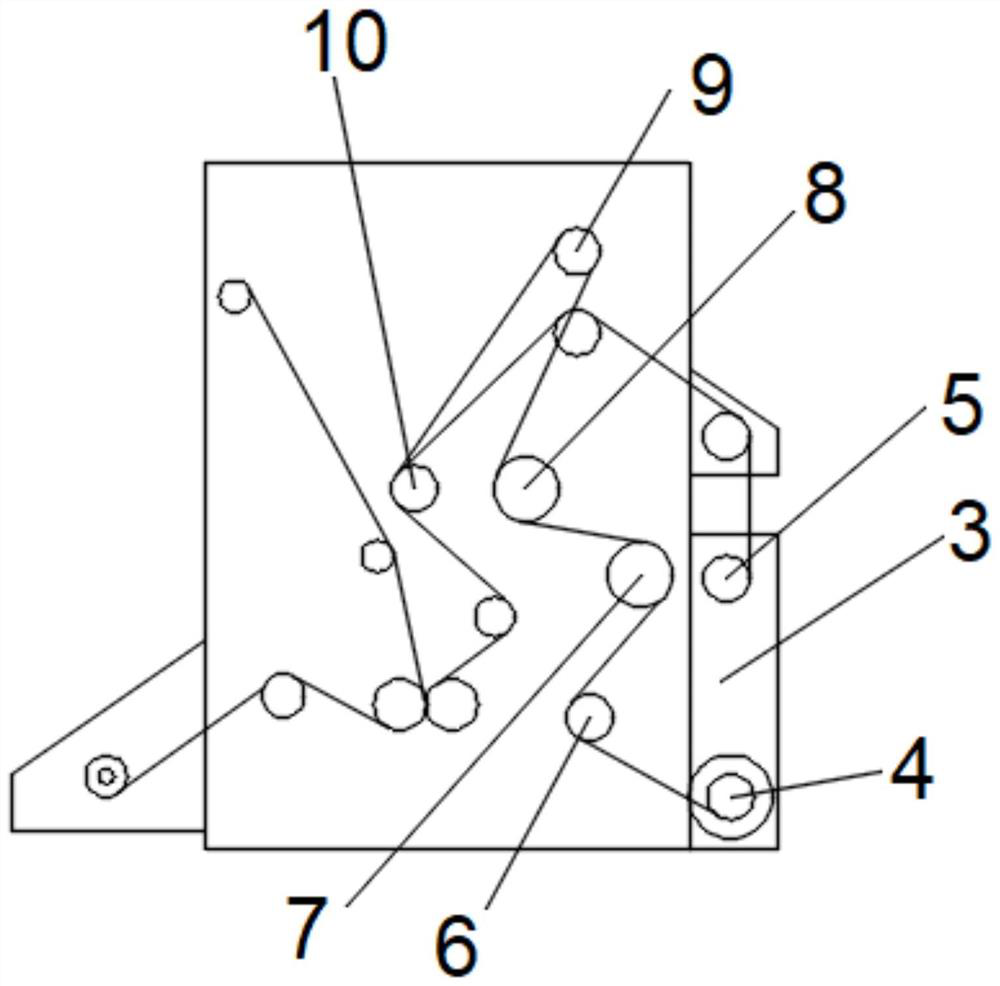

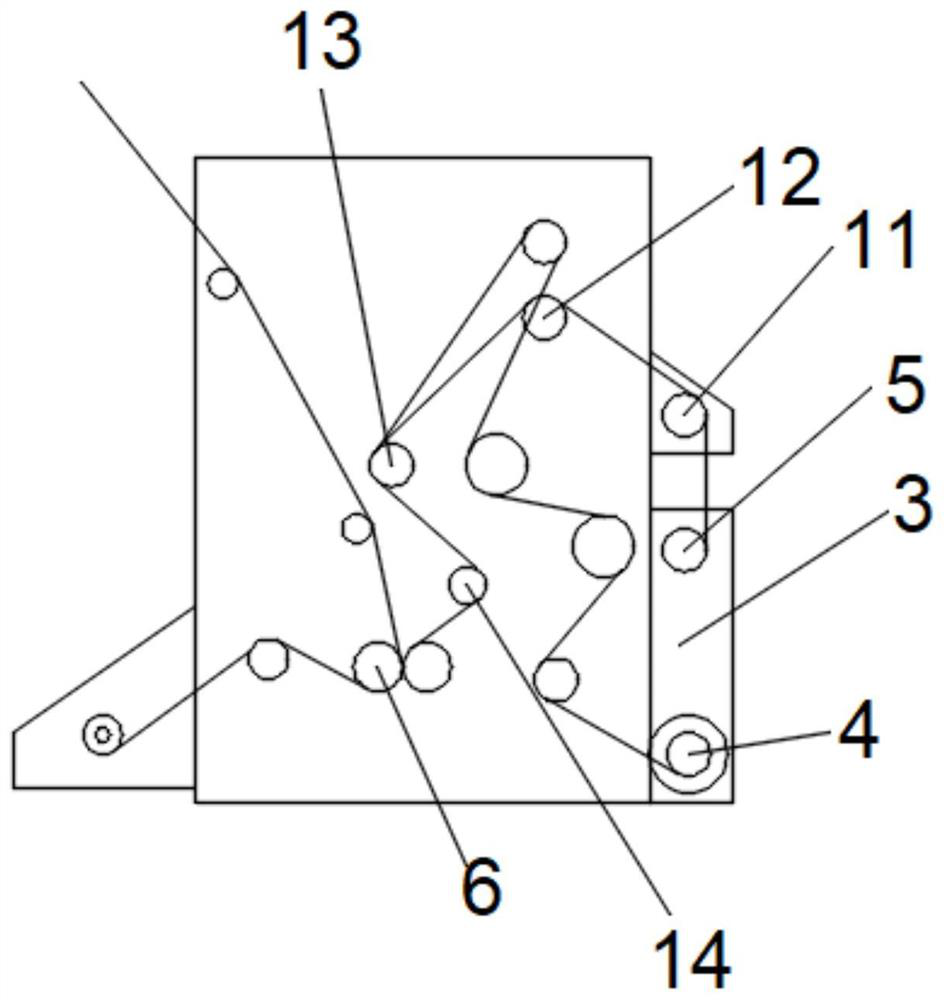

[0046] The anion-yang membrane dual-mode composite mechanism includes: a first frame 1, a mounting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com