A kind of boron-doped diamond film electrode foam ceramic substrate and preparation method thereof

A technology of boron-doped diamond and thin-film electrodes, which is applied in the fields of boron-doped diamond thin-film electrode foam ceramic substrate and its preparation, boron-doped diamond thin-film electrodes and its preparation, and can solve the problems of shortened service life and damage of boron-doped diamond thin-film electrodes, Achieve the effect of reducing impact force and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Boron-doped diamond thin film electrode foam ceramic matrix

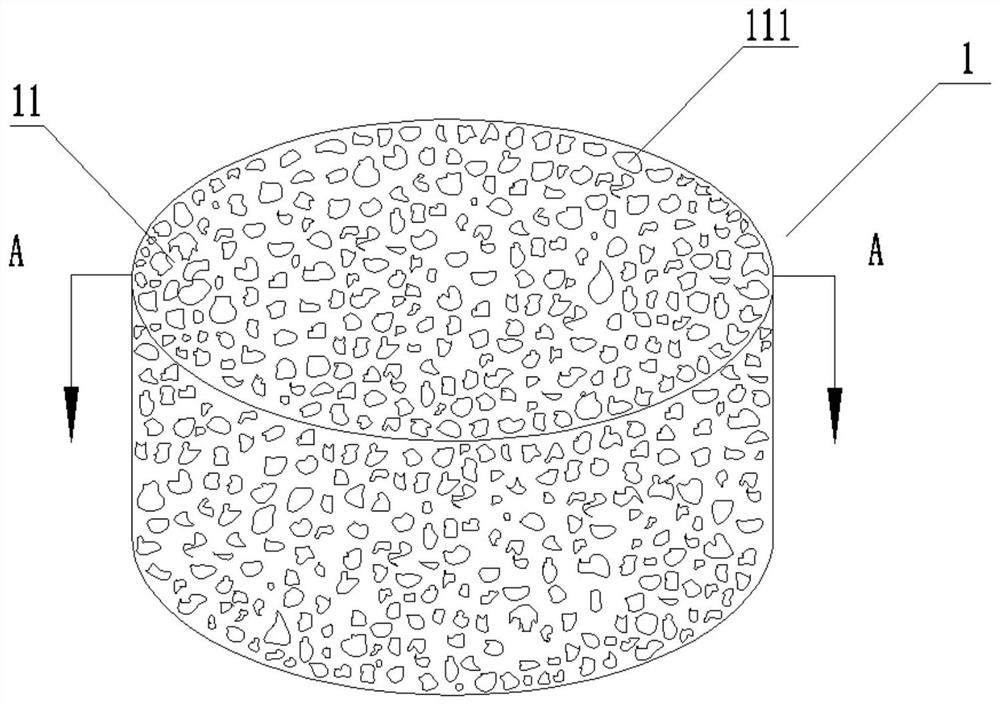

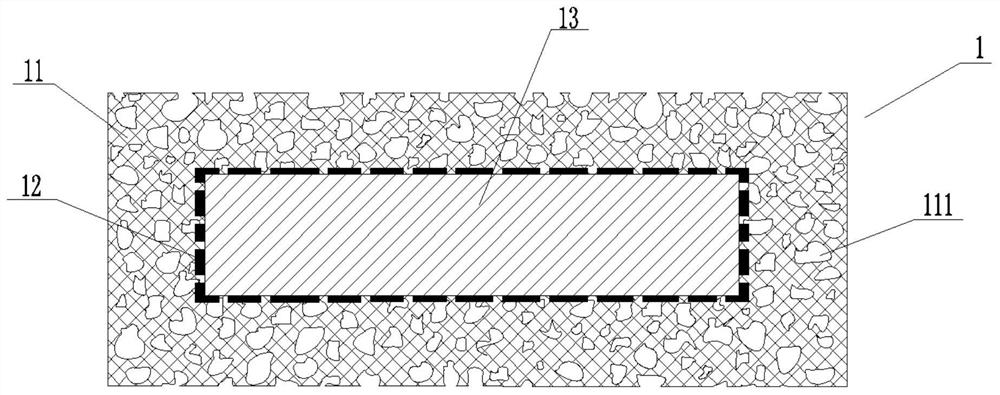

[0027] figure 1 A three-dimensional view of the foamed ceramic substrate of the boron-doped diamond thin film electrode in this embodiment is shown, figure 2 The edge of the foamed ceramic matrix of the boron-doped diamond thin film electrode in this example is shown. figure 1 A cross-sectional view in the A-A direction.

[0028] like figure 1 and figure 2As shown, the boron-doped diamond thin film electrode foamed ceramic substrate 1 of this embodiment includes a core portion 13 in the center, a middle portion 12 and a boron-doped diamond thin film deposition portion 11 . The intermediate portion 12 is attached to the outer surface of the core portion 13 at intervals. The boron-doped diamond thin film deposition portion 11 is located on the outer surface of the intermediate portion 12 and the exposed face of the core portion 13 at the interval between the intermediate portion 12 . The co...

Embodiment 2

[0034] Example 2: Preparation method of boron-doped diamond thin film electrode foam ceramic matrix

[0035] This embodiment provides a method for preparing a boron-doped diamond thin film electrode foamed ceramic substrate according to Embodiment 1, which includes the following steps:

[0036] S1, the ceramic powder is pre-pressed and then sintered to prepare the core of the boron-doped diamond thin film electrode foam ceramic matrix;

[0037] S2. Cut the energy-absorbing material to a predetermined size, attach it to the outer surface of the core at intervals, and coat the outer surface of the energy-absorbing material attached to the outer surface of the core with a heat insulating material to obtain a boron-doped diamond film The middle part of the electrode foam ceramic substrate;

[0038] S3, preparing a ceramic slurry containing the ceramic powder, sintering aid and foaming agent used in step S1;

[0039] S4. Injecting part of the ceramic slurry into the mold and pa...

Embodiment 3

[0042] Example 3: A Boron-Doped Diamond Thin Film Electrode

[0043] A boron-doped diamond thin film electrode of this embodiment includes the foamed ceramic substrate of the boron-doped diamond thin film electrode of Embodiment 1.

[0044] The boron-doped diamond thin film electrode of this embodiment has the foamed ceramic substrate of the boron-doped diamond thin film electrode of Embodiment 1, which will not be damaged by the impact force generated by the fluid colliding with the pore walls of the pores of the foamed ceramic substrate during use, nor will it be damaged during use. The boron-doped diamond thin film electrode in this embodiment has a long service life because it may be dislodged from the installation position due to impact force. In addition, the boron-doped diamond thin film electrode of this embodiment has the beneficial effects of the boron-doped diamond thin film electrode foamed ceramic substrate of the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com