Electrolyte-resistant associated alkali swelling thickener as well as preparation method and application thereof

A technology resistant to electrolytes and thickeners, applied in applications, household appliances, coatings, etc., can solve the problems of reduced thickening performance, restrictions on the application of alkali-swellable thickeners, poor thickening effects, etc., to achieve thickening High efficiency, low toxicity, and good electrolyte resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

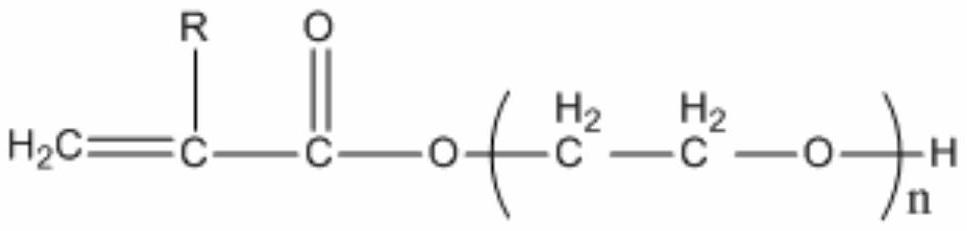

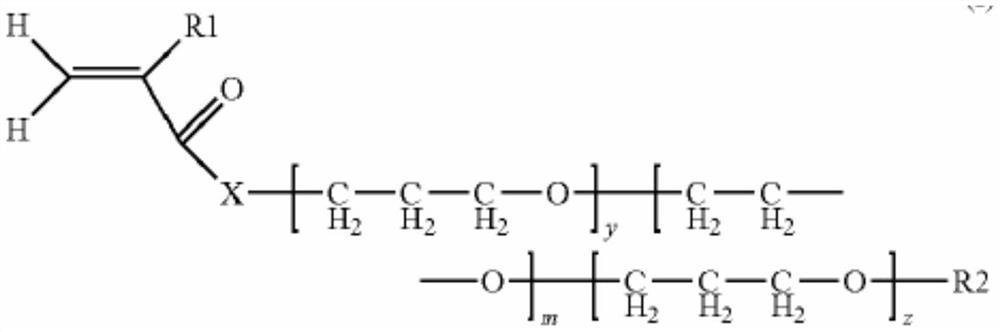

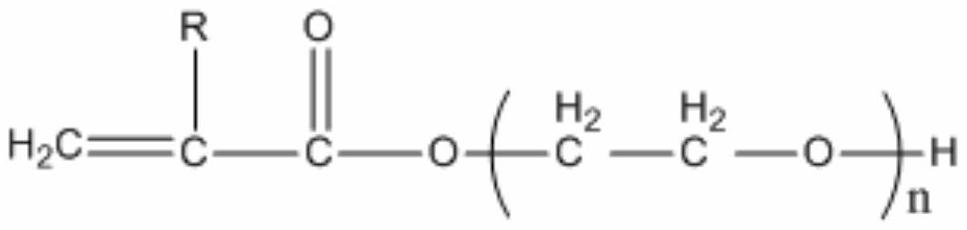

Method used

Image

Examples

Embodiment 1

[0036] (1) Pour 260g of deionized water into the reactor, add 5g of sodium dodecylsulfonate, and heat up to 82°C under stirring;

[0037] (2) dissolve 0.3g ammonium persulfate with 60g deionized water, be mixed with initiator solution;

[0038] (3) Take a beaker and mix the following monomers evenly: 105g ethyl acrylate, 35g methacrylic acid, 1.5g BASF BEPEGMA and 0.09g N'N methylenebisacrylamide, take 7.5g mixed monomer and 3g step (2 ) Gained initiator solution is added respectively in step (1) reactor and is incubated 30min;

[0039] (4) Add the remaining mixed monomer and the remaining initiator solution to the reactor dropwise for 2.5 hours. After the dropwise addition, keep warm for 1 hour to obtain an electrolyte-resistant associative alkali-swelling thickener.

Embodiment 2

[0041] (1) Pour 260g of deionized water into the reactor, add 5g of sodium dodecylsulfonate, and heat up to 82°C under stirring;

[0042] (2) dissolve 0.3g ammonium persulfate with 60g deionized water, be mixed with initiator solution;

[0043] (3) Take a beaker and mix the following monomers evenly: 100g ethyl acrylate, 35g methacrylic acid, 5g acrylamide, 1.5g BASF BEPEGMA and 0.09g N'N methylenebisacrylamide, take 7.5g mixed monomer and 3g step (2) gained initiator solution joins respectively in step (1) reactor and is incubated 30min;

[0044] (4) Add the remaining mixed monomer and the remaining initiator solution to the reactor dropwise for 2.5 hours. After the dropwise addition, keep warm for 1 hour to obtain an electrolyte-resistant associative alkali-swelling thickener.

Embodiment 3

[0046] (1) Pour 260g of deionized water into the reactor, add 5g of sodium dodecylsulfonate, and heat up to 82°C under stirring;

[0047] (2) dissolve 0.3g ammonium persulfate with 60g deionized water, be mixed with initiator solution;

[0048] (3) Take a beaker and mix the following monomers evenly: 100g ethyl acrylate, 35g methacrylic acid, 5g 2-acrylamido-2-methylpropanesulfonic acid, 1.5g BASF BEPEGMA and 0.09g N'N methylene For bisacrylamide, take 7.5g of mixed monomers and 3g of the initiator solution obtained in step (2), and add them to the reactor of step (1) to keep warm for 30min;

[0049] (4) Add the remaining mixed monomers and the remaining initiator solution to the reactor dropwise for 2.5 hours, and keep warm for 1 hour after the dropping to obtain the electrolyte-resistant associative alkali-swelling thickener.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com