A method for consolidating silty sand layers

A silt and sand layer technology, applied in soil protection, infrastructure engineering, sheet pile walls, etc., can solve the problems of increasing the safety risk of foundation pit excavation, slope instability, consumption of large resources, and low construction risk. , to achieve the effect of simple and easy operation, high promotion prospect and low construction risk in the initial reinforcement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate understanding of the present invention, the present invention will be described more fully below in conjunction with specific embodiments.

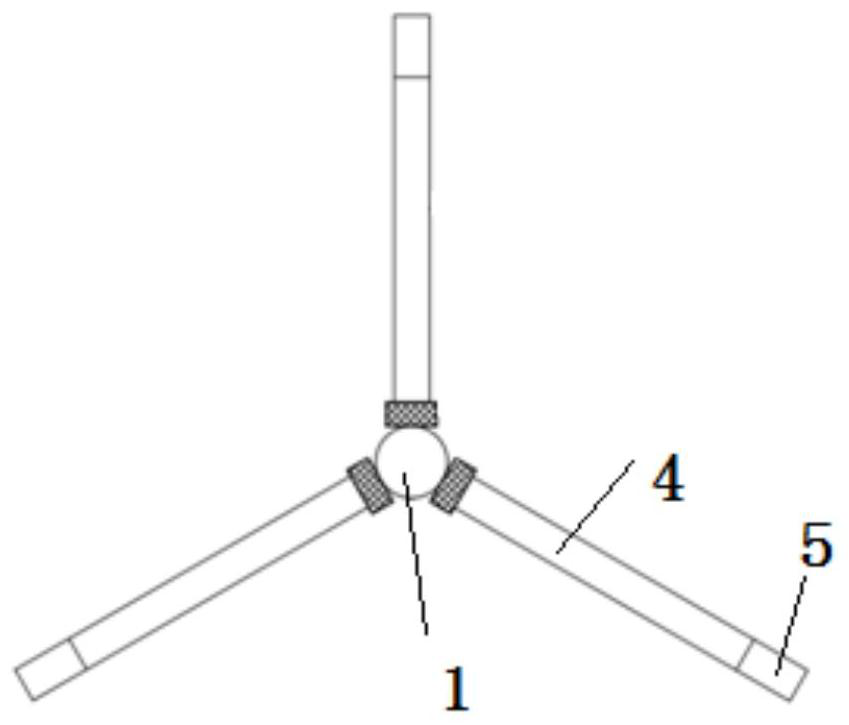

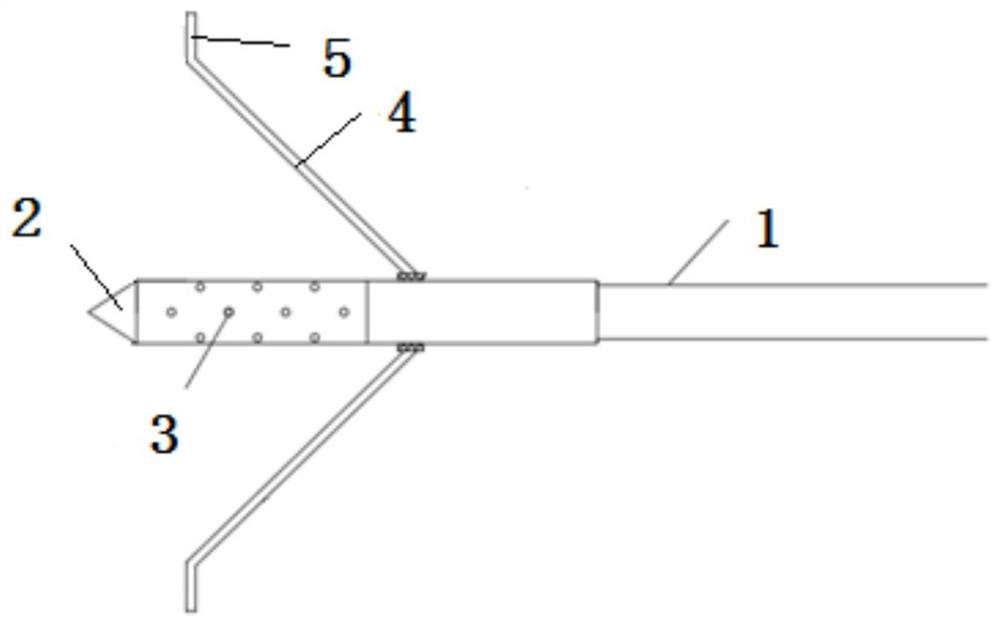

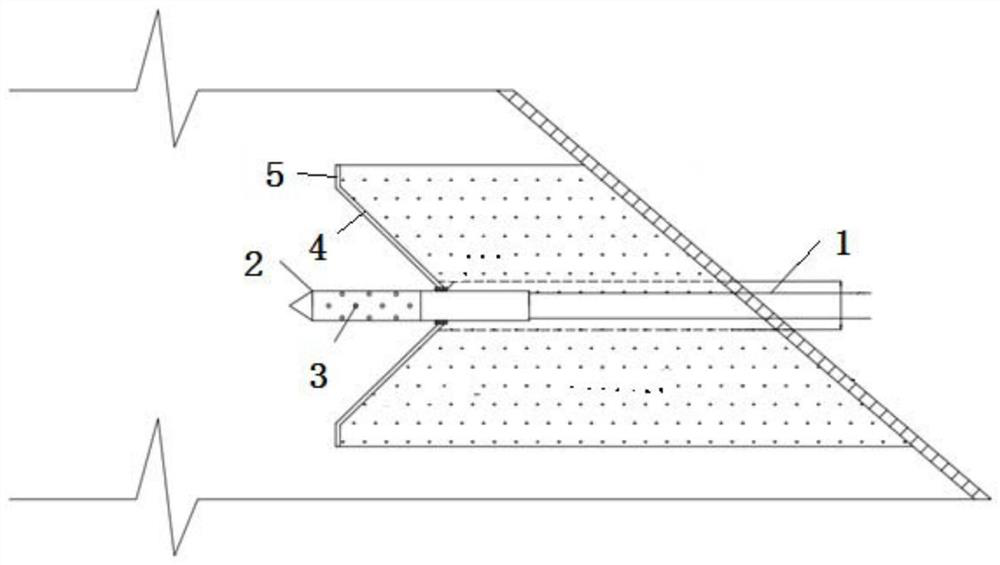

[0033] Such as Figure 1-5 As shown, a method for reinforcing the silty sand layer includes a stirring drill and a long anchor pipe 6. The drill bit part of the stirring drill includes a drill rod 1, and the drill rod 1 is provided with a cement grout For the liquid injection chamber that enters and exits, one end of the drill pipe 1 is provided with a drill bit 2 and the other end is provided with a grouting hole. The drill bit 2 is provided with at least two grouting holes 3 connected to the liquid injection chamber.

[0034] The side wall of the drill pipe 1 is provided with a stirring blade 4, and the other end of the stirring blade 4 is provided with a trigger protrusion 5. When the trigger protrusion 5 is subjected to the resistance directed from the drill bit 2 to the drill pipe 1, the stirring blade 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com