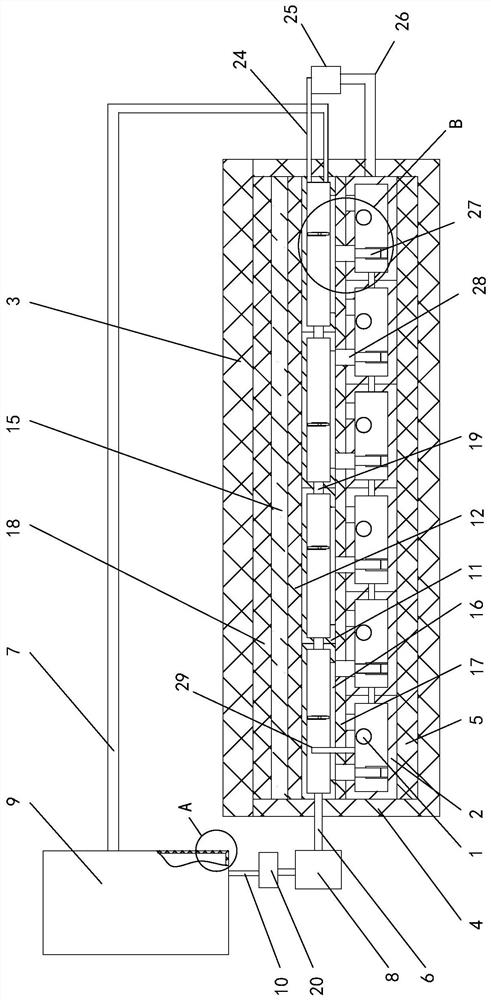

Fireproof electric floor heating structure

A technology of electric floor heating and fireproof layer, applied in the field of floor heating, can solve the problems of complicated installation process of electric floor heating, affecting user experience, uneven heating effect, etc., achieving the effect of simple installation, easy installation and disassembly, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

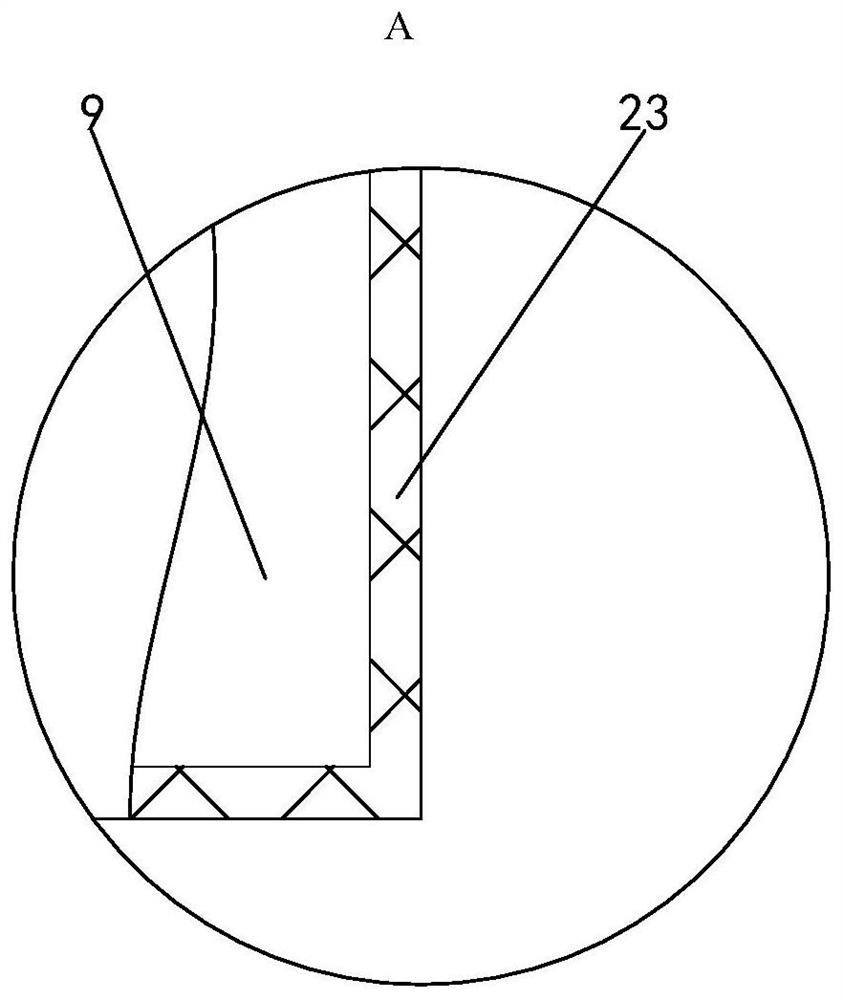

[0029] As a specific embodiment of the present invention, the first number column 28 is located at one end of the adjacent impeller 32 close to the water storage tank 9, and the first number column 28 is used to push the water in the water storage tank 11 to the impeller 32; When the first column 28 is farther away from the fan 25 than the adjacent impeller 32, when the first column 28 hits the water storage tank 11, the water flow in the water storage tank 11 will quickly impact the impeller 32, thereby further increasing the rotation speed of the impeller 32. , and then increase the rotation speed of No. 2 fan blade 31; the faster rotation of No. 2 fan blade 31 improves the moving speed of gas, thereby reducing the workload of fan 25 and indirectly increasing the rotation speed of No. 1 fan blade 27 , and then make the No. 1 pillar 28 hit the water storage tank 11 more violently.

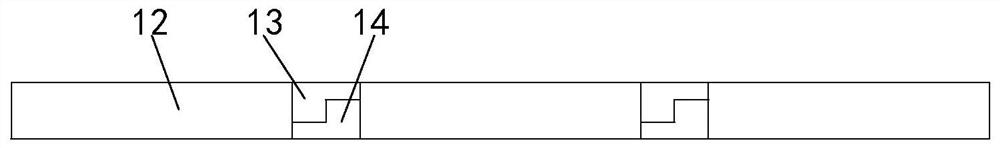

[0030] As a specific embodiment of the present invention, the bottom end of the floor 3 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com