Batch workpiece airtightness detection method based on artificial intelligence

An artificial intelligence, workpiece technology, applied in the direction of using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of difficult to determine whether the leakage position is the same part of the workpiece, different poses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The main purpose of the invention is to realize the airtight detection of batch workpieces.

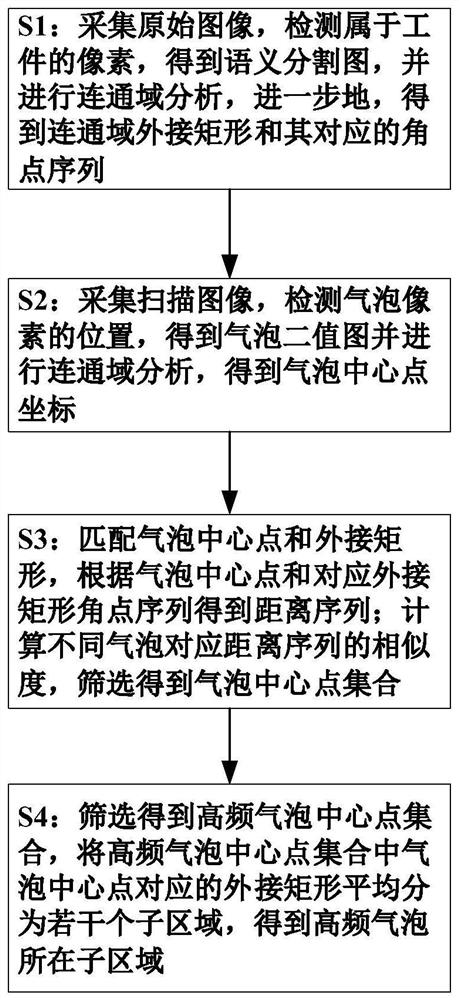

[0032] In order to realize the contents of the present invention, the present invention designs a method for airtight detection of batch workpieces based on artificial intelligence, the method flow chart is as follows figure 1 shown.

[0033] Step S1:

[0034] In the present invention, an RGB camera is used to photograph the airtightness detection device for airtightness analysis, and the airtightness detection device is a glass cylinder in which there is a certain amount of water. The camera is fixed directly above the air-tightness detection device, and photographs the air-tightness detection device in a bird's-eye view.

[0035] Put several similar workpieces into the air-tightness detection device by a mechanical arm or manually, and turn on the camera to collect the original image of the air-tightness detection device after placing the workpieces.

[0036] The present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com