Dental implant embedding tool

A technology for dental implants and tooling, applied in dental prosthesis, dentistry, measuring devices, etc., can solve problems such as high labor intensity, high scrap rate, skew, etc., and achieve improved efficiency and accuracy, good balance and stability , the effect of easy connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

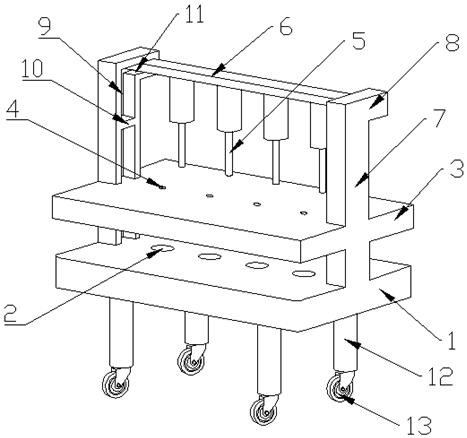

[0047] Such as figure 1 As shown, this embodiment provides a dental implant embedding tool, including a base plate 1, a placement groove 2 for accommodating a sleeve is provided on the base plate 1, a top plate 3 is provided above the bottom plate 1, and the top plate 3 is parallel to the bottom plate 1 and the top plate 3 and the bottom plate 1 are connected by a connecting frame; the top plate 3 is provided with a guide hole 4 for dental implants to pass through, and the guide hole 4 corresponds to the placement groove 2 And the axis of the guide hole 4 is perpendicular to the bottom surface of the placement groove 2; the top of the top plate 3 is provided with a lower pressing rod 5, and the lower pressing rod 5 corresponds to the guide hole 4 and can be inserted from the guide hole 4. Through it, the lower pressing rod 5 can move up and down and a limiting device is arranged on the track where it moves up and down.

[0048] In order to improve embedding efficiency and sav...

Embodiment 2

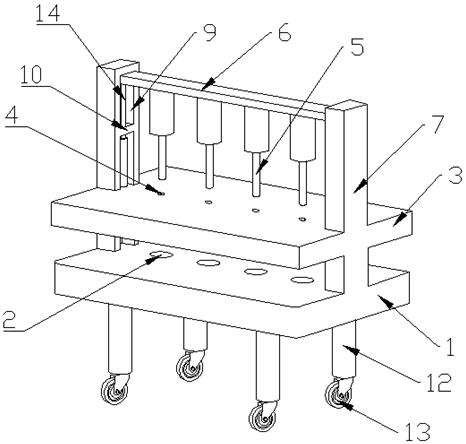

[0058] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are: figure 2 As shown, the present embodiment adopts an automatic driving mode to drive the connecting rod 6 and the lower pressing rod 5 to move, the connecting rod 6 is connected with a linear drive device 14, the output shaft of the linear drive device 14 is connected to the connecting rod 6 and can Drive described connecting rod 6 to move up and down.

[0059] Specifically, the linear drive device 14 may adopt linear motors, electric push rods, hydraulic cylinders, air cylinders and other devices that output linear motion.

[0060] In this embodiment, the main body of the driving device 14 is installed at the position below the limit block 10 in the track 9, and the output shaft of the drive device 14 passes through the limit block 10 and is connected to the connecting rod 6, so that it can...

Embodiment 3

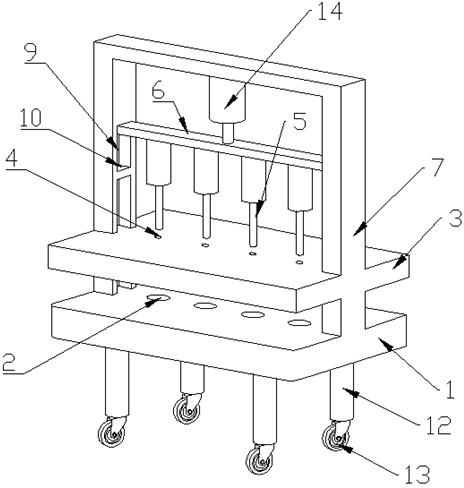

[0064] The same features of this embodiment and Embodiment 2 will not be described in detail. The different features of this embodiment and Embodiment 2 are: image 3 As shown, the bracket 7 of this embodiment forms the shape of a gantry, and the driving device 14 is arranged on the beam of the gantry to realize the driving of the connecting rod 6 and the pressing rod 5 .

[0065] The working principle of this embodiment is the same as that of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com