Liquid specific heat capacity measuring system and measuring method

A measurement system and specific heat capacity technology, applied in the direction of thermal development of materials, can solve the problems of low accuracy, narrow temperature range, narrow temperature measurement range, etc., to achieve the effect of improving measurement accuracy, improving accuracy and reducing heat dissipation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

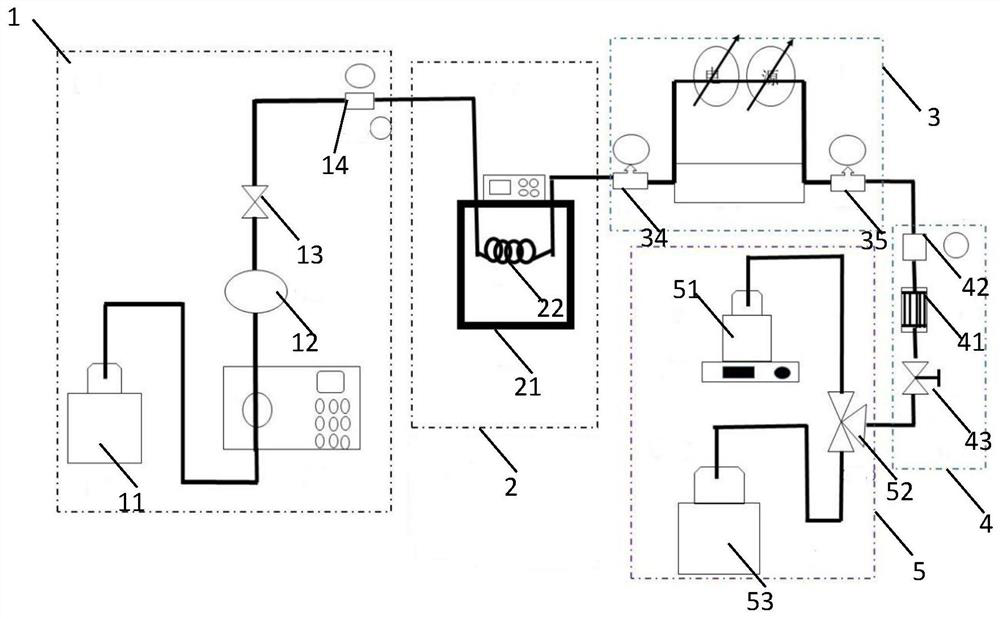

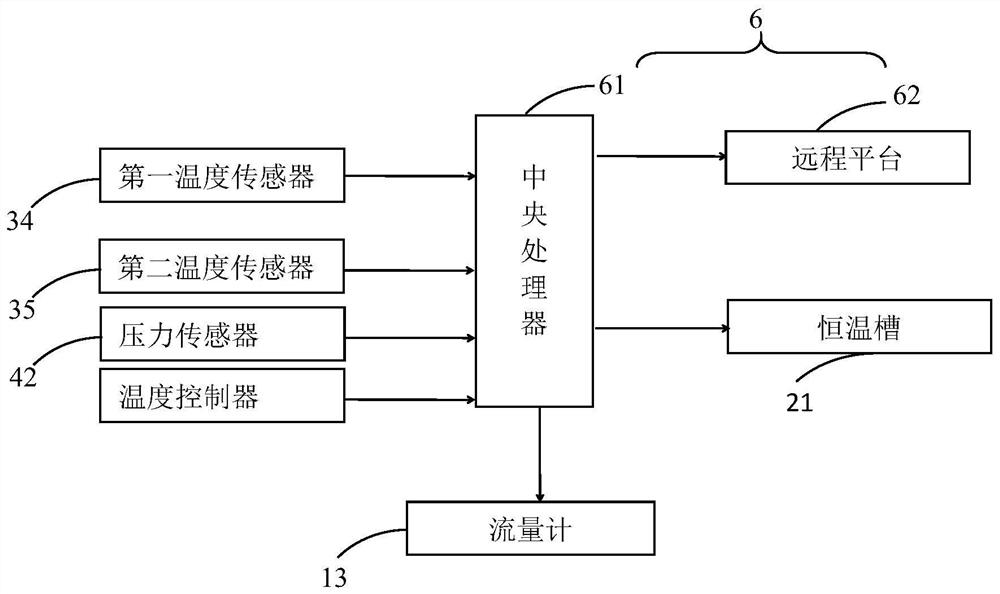

[0039] See attached figure 1 As shown, Embodiment 1 of the present invention discloses a liquid specific heat capacity measurement system, comprising: a power unit 1, a preheating unit 2, a testing unit 3, a pressure control unit 4, a sampling unit 5 and a data processing unit 6,

[0040] The power part 1, the preheating part 2, the test part 3, the pressure control part 4 and the sampling part 5 are sequentially connected and communicated through pipelines, and the data processing part 6 is electrically connected with the test part 3 and the power part 1;

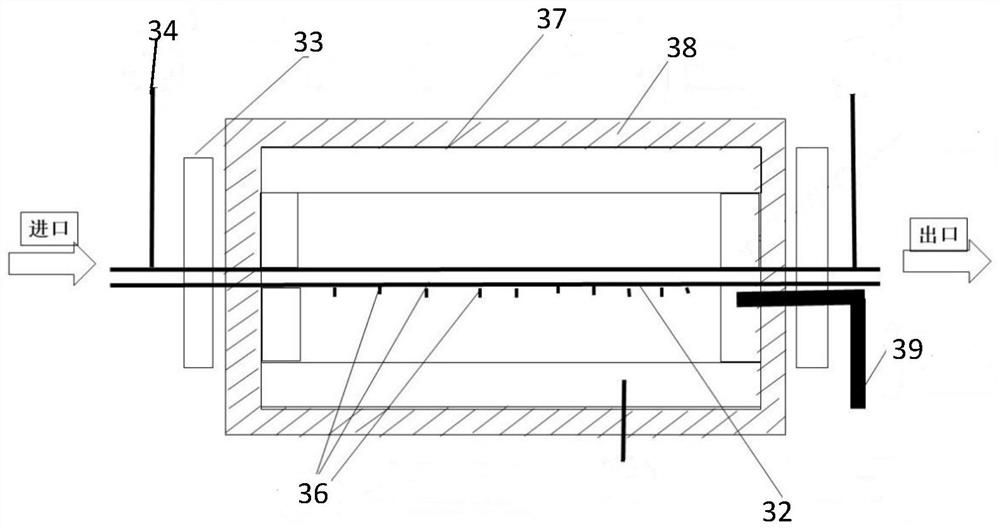

[0041] Wherein, the test section 3 specifically includes: a heat preservation device 31, a test pipeline 32, a heating device 33 and a cooling pipe 39, the heat preservation device 31 is arranged on the test pipe 32, the heating device 33 is arranged on both sides of the test pipe 32, and the cooling pipe 39 is arranged Under the test pipe 32 and inside the heating device 33, there is cooled nitrogen gas.

[0042] Specifi...

Embodiment 2

[0056] This embodiment 2 provides a method for measuring the specific heat capacity of a liquid, including:

[0057] S1: Test the flow rate of the liquid through the flowmeter 13, respectively detect the inlet temperature and the outlet temperature of the test pipeline 32 through the first temperature sensor 34 and the second temperature sensor 35 to obtain the temperature rise of the liquid, and measure the quality of the liquid with the balance 51. The expression of the specific heat capacity of the liquid obtained from the parameters is:

[0058]

[0059] In the formula, C pexp is the specific heat capacity, m is the mass of the liquid, ΔT is the temperature rise, Q L is the heat loss, c p is the experimental specific heat capacity;

[0060] Among them, the expression of temperature rise is: ΔT=T m -T b

[0061] In the formula, T m is the outlet temperature, T b is the inlet temperature;

[0062] Among them, P is the heating power, T m

[0063] S2: Judging t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com