Current-carrying friction micro-area surface force-heat-electric load distribution test system and method

A current-carrying friction and distribution testing technology, applied in thermometers, analytical materials, measuring devices, etc., which use electrical/magnetic components directly sensitive to heat. Problems such as the transient nature of sexual contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

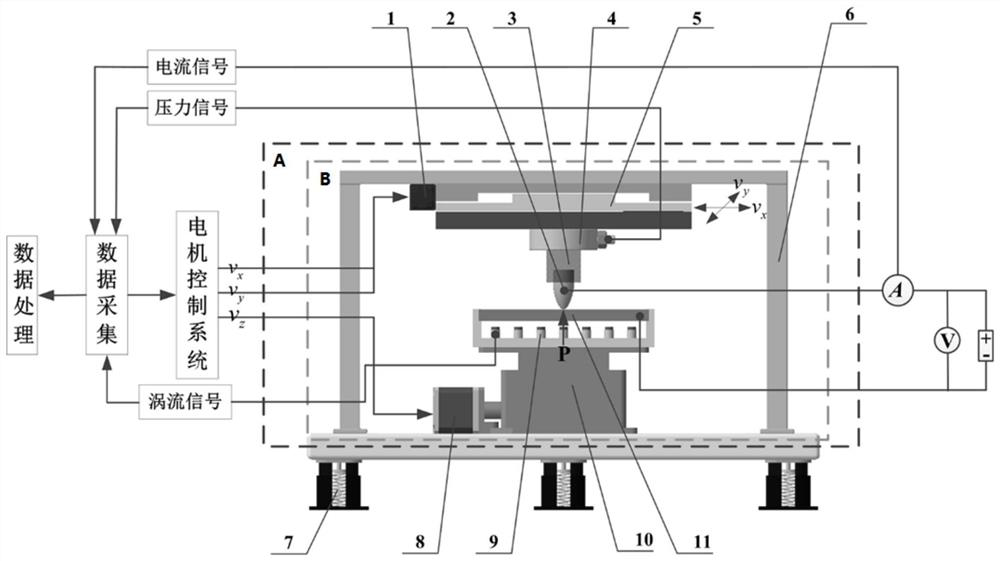

[0036] Example of test system

[0037] Such as figure 1 It is a system for testing the force-thermal-electric load distribution on the surface of the current-carrying friction micro-zone.

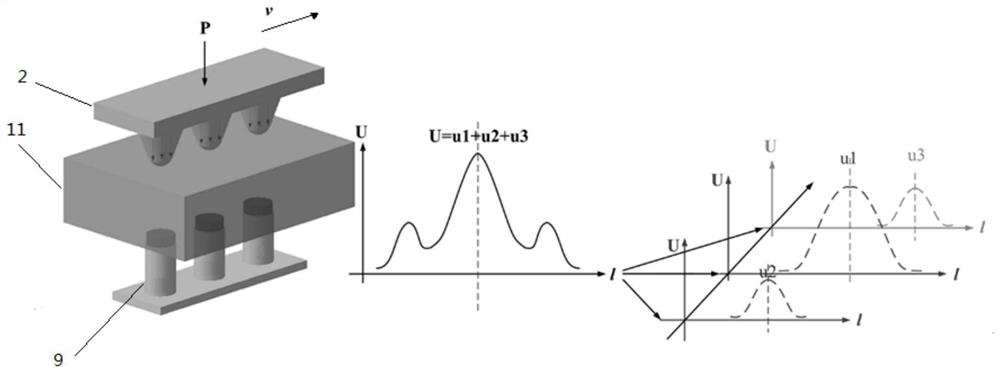

[0038] The tested friction pair includes an upper sample 2 and a lower sample 11. The upper sample 2 is a needle sample, that is, a sample with a needle-like tip, whose tip is in contact with the surface of the lower sample 11; from a microscopic point of view , that is, the micro-convex peaks on the protrusion contact and rub against the micro-convex peaks on the lower sample surface.

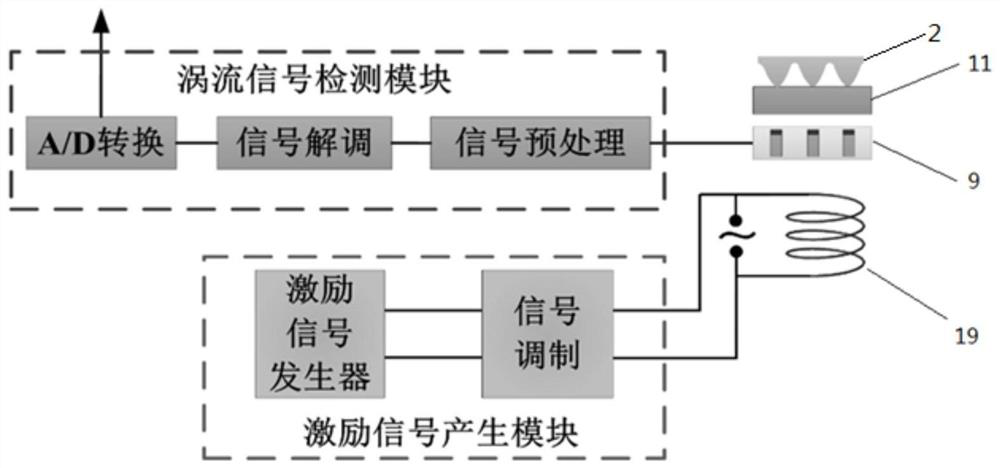

[0039] The system mainly includes a sample fixture 3, which is used to clamp the upper sample 2; a disc-shaped support frame, which is used to support and fix the lower sample 11, and a plurality of eddy current sensors are arranged in the disc-shaped support frame below the lower sample 11 9. Form an eddy current sensor array. An excitation coil 19 is arranged below the eddy current sensor array for gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com