A kind of preparation technology of epoxy resin adhesive

A technology of epoxy resin and preparation process, which is applied in the direction of transportation and packaging, mixer with rotating stirring device, dissolution, etc., which can solve the problems that the adhesive cannot be uniformly tempered, the adhesive is not poured completely, and the adhesive has a low degree of fineness. , to avoid quality decline, improve uniform viscosity and fineness, and avoid increased resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

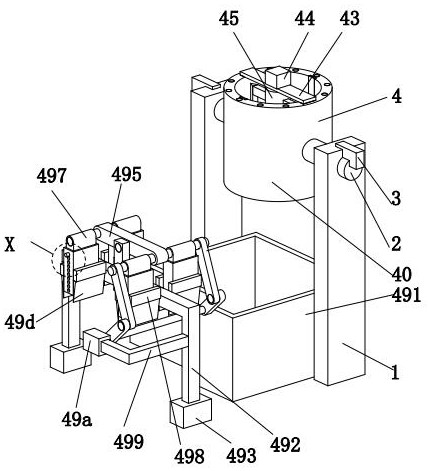

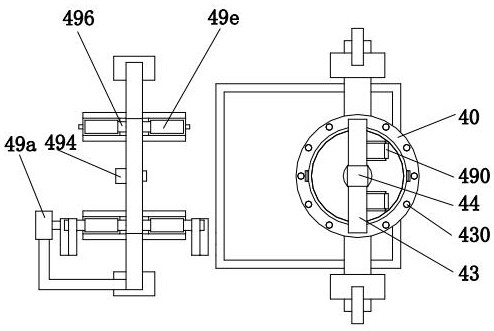

[0040] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

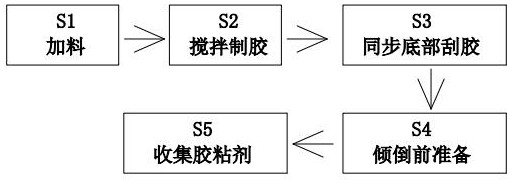

[0041] like Figure 1 to Figure 11 A kind of epoxy resin adhesive preparation process shown, it has used a kind of epoxy resin adhesive preparation device, this epoxy resin adhesive preparation device comprises vertical frame 1, fixed rod 2, block 3 and stirring mechanism 4, adopts epoxy resin When the resin adhesive preparation device prepares epoxy resin adhesive, the specific preparation process is as follows:

[0042] S1, feeding: Pour the raw materials required for preparing the epoxy resin adhesive into the mixing tank 40 by manual means;

[0043] S2. Stirring and making glue: drive the hollow shaft 45 to rotate through the No. 1 motor 44, and the fixed shaft 47 rotates horizontally with the hollow shaft 45 synchronously. At the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com