Composite ultrasonic vibration stirring ball-milling equipment and use method

A technology of vibration stirring and composite ultrasound, which is applied in the direction of grain processing, etc., can solve the problems of easy agglomeration of fine powder particles, affecting the uniformity of powder ball milling, the quality of mixed powder, and the tendency of powder slurry to stick to the wall and bottom, etc., to achieve The adhesion effect is strengthened, the particle size uniformity is improved, and the effect of avoiding the deterioration of the grinding effect is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

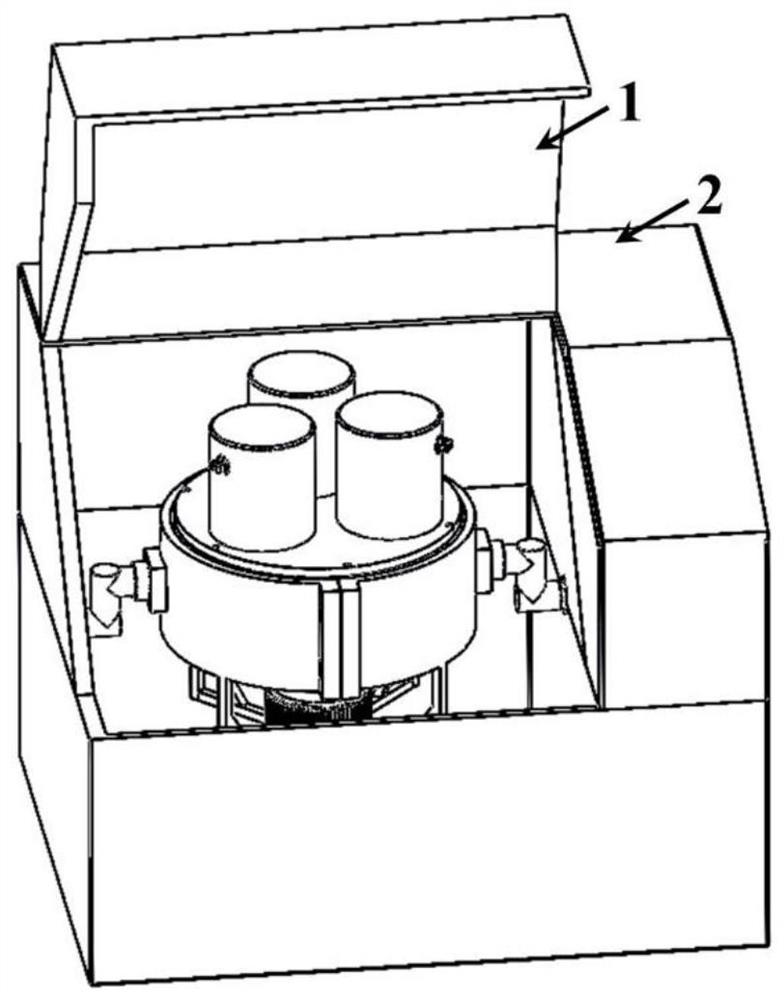

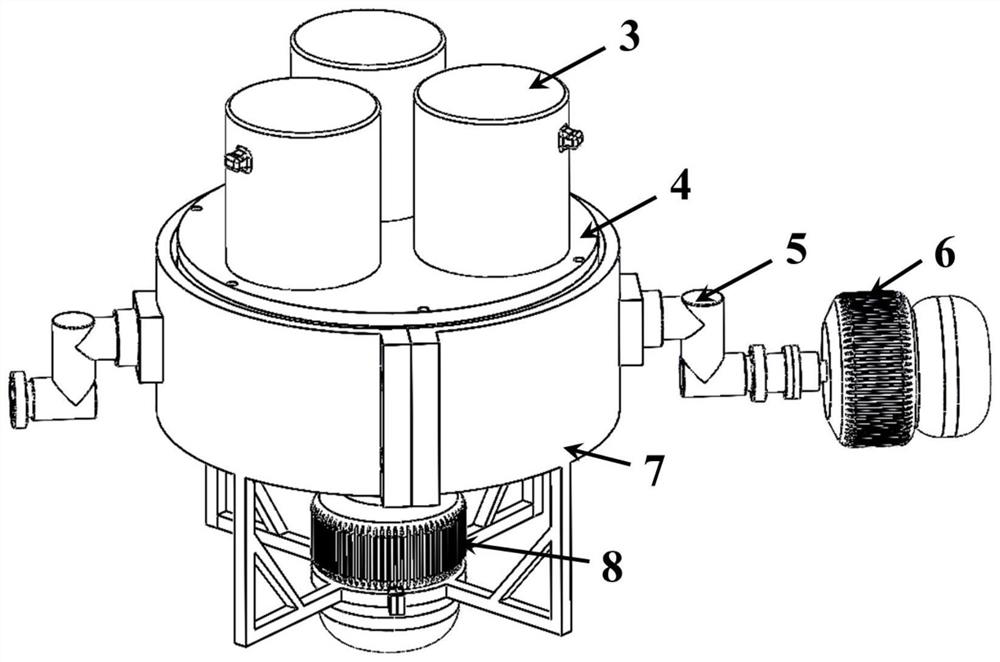

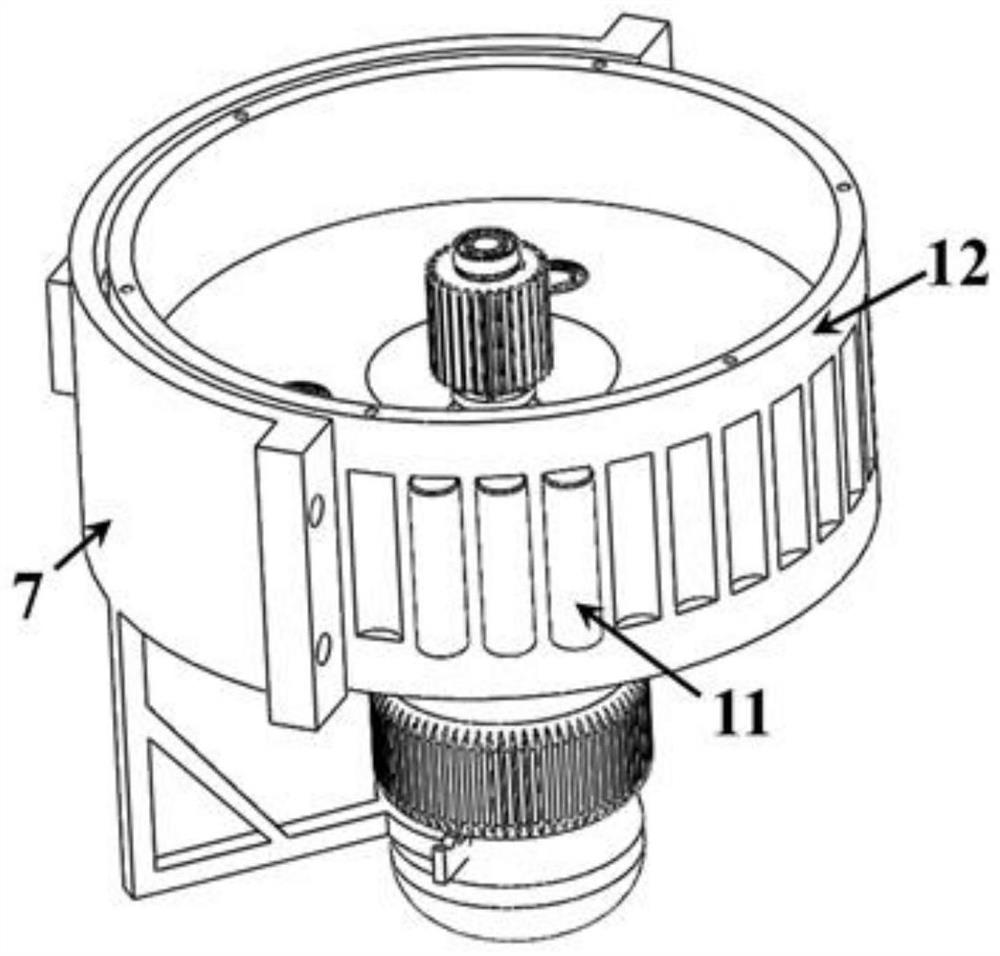

[0026] Such as Figure 1-7 As shown, the present invention provides a compound ultrasonic vibration stirring ball milling equipment, including an outer shell 2, a ball milling tank 3, a fixed frame 7 and a transmission mechanism, and the inside of the ball milling tank 3 is provided with an ultrasonic vibration stirring claw 19 and a spherical ultrasonic oscillator 20. The transmission mechanism includes a rotary base 12, a rotating shaft 5, a central gear 10, a planetary gear 9, a longitudinal motor 6, an epicyclic motor 8 and a central motor 15. The ball mill pot 3 is installed on the upper sealing cover 4, and the upper The sealing cover 4 is connected with the rotary base 12 through bolts; the outer wall of the rotary base 12 is provided with a concave area that can accommodate the rotating roller 11, and the inner wall of the fixed frame 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com