Anti-loosening nut and production equipment

A production equipment and anti-loosening technology, used in nuts, metal processing equipment, lighting and heating equipment, etc., can solve the problems of no humidification and dust reduction, poor shock absorption effect, and insignificant heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

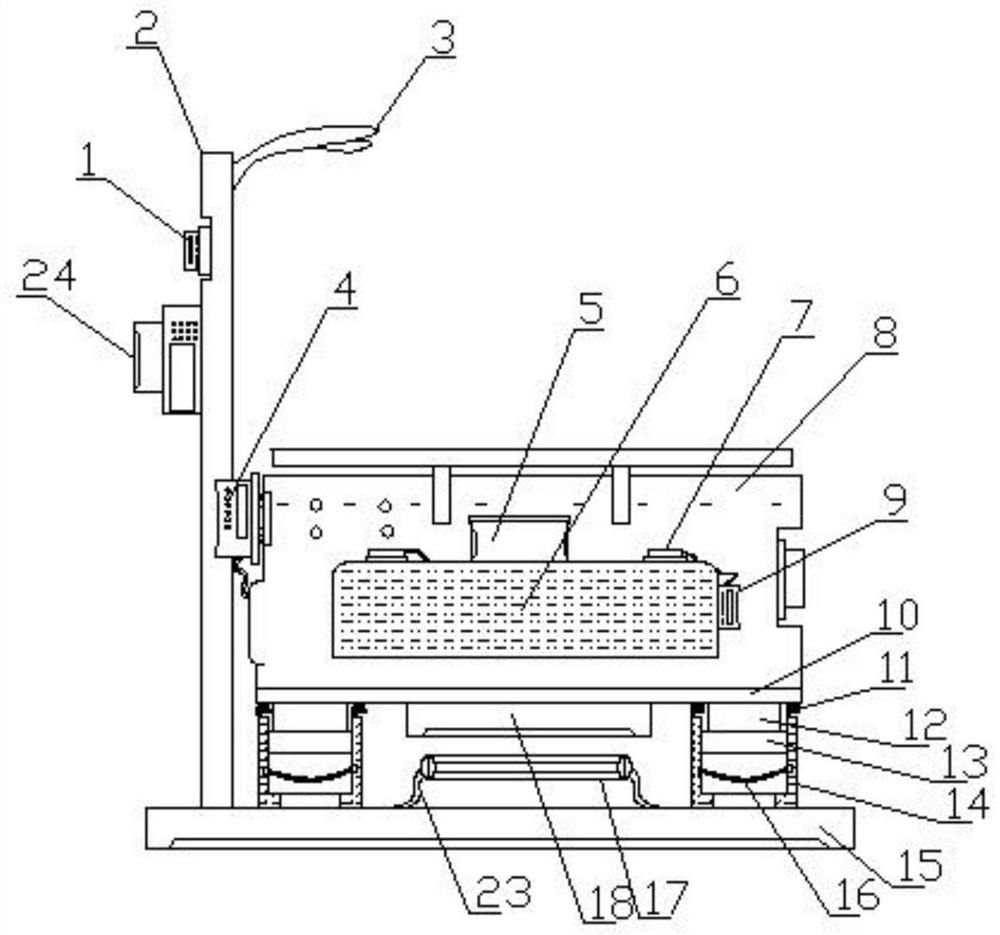

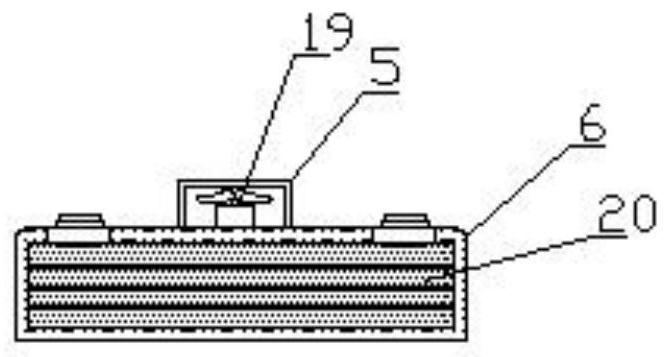

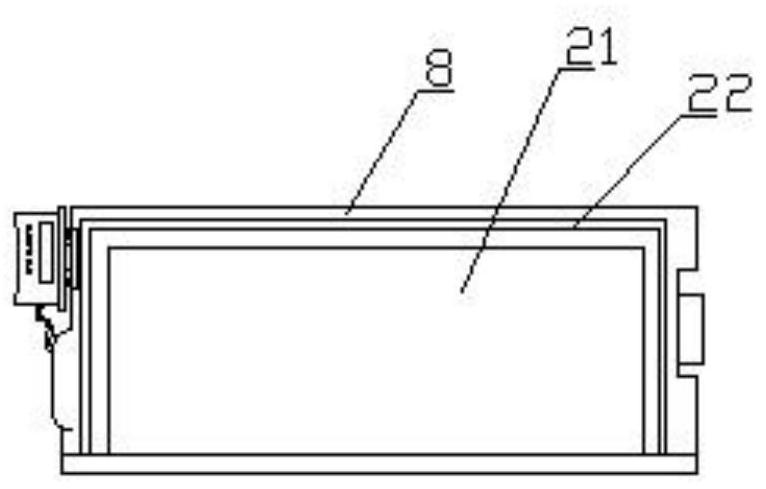

[0024] like Figure 1-3 As shown, a kind of anti-loosening nut and production equipment include a base 15, a support plate 10 and an automatic nut cold heading machine 21, the two ends of the top of the base 15 are installed with a sleeve 14 by bolts, and the inner bottom of the sleeve 14 The PP buffer film 16 is installed by screws, the sleeve 14 is provided with a piston 13, the top of the piston 13 is installed with a support column 12 by bolts, and the top of the support column 12 is welded to the support plate 10, and the top of the support plate 10 A protective cover 8 is installed through screws, one side of the protective cover 8 is installed with a refrigeration box 6 through screws, one side of the refrigeration box 6 is installed with a microcomputer time control switch 9 through screws, and the two ends of the top of the refrigeration box 6 pass through The installation groove installs the semiconductor refrigeration sheet 7, the air inlet 5 is arranged between the...

Embodiment 2

[0038] like Figure 1-3 As shown, a kind of anti-loosening nut and production equipment include a base 15, a support plate 10 and an automatic nut cold heading machine 21, the two ends of the top of the base 15 are installed with a sleeve 14 by bolts, and the inner bottom of the sleeve 14 The PP buffer film 16 is installed by screws, the sleeve 14 is provided with a piston 13, the top of the piston 13 is installed with a support column 12 by bolts, and the top of the support column 12 is welded to the support plate 10, and the top of the support plate 10 A protective cover 8 is installed through screws, one side of the protective cover 8 is installed with a refrigeration box 6 through screws, one side of the refrigeration box 6 is installed with a microcomputer time control switch 9 through screws, and the two ends of the top of the refrigeration box 6 pass through The installation groove installs the semiconductor refrigeration sheet 7, the air inlet 5 is arranged between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com