Waterproof geopolymer material and preparation method thereof

A geopolymer and waterproof technology, applied in the field of waterproof geopolymer materials and their preparation, can solve the problems of high price, difficult to popularize and use, poor durability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

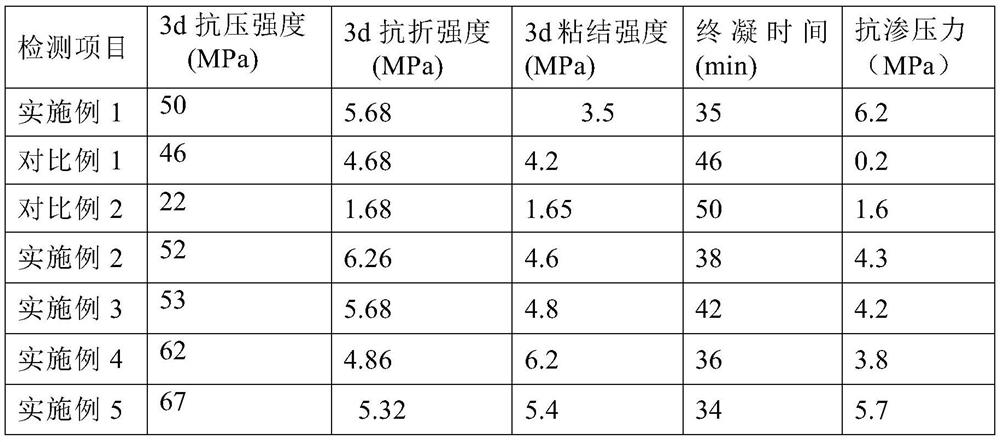

Examples

Embodiment 1

[0031] In this embodiment, the preparation process of the waterproof polymer material is as follows:

[0032] Put 0.06 parts of modified nano-magnesium oxide and 0.08 parts of dispersant in 9 parts of water, stir for 240s, and then put it under the power of 700W for 0.5h to obtain a uniform mixed solution; then weigh 40 parts of fly ash, 26 Pour phosphorus slag, 10 parts of ordinary Portland cement, 7 parts of sodium bentonite into the mixing pot, stir for 90 seconds to obtain the mixture particles, then mix the obtained mixture particles, 0.01 parts of admixture, 4 parts of sodium hydroxide solid and Add 5 parts of sodium silicate solids into the muffle furnace (setting temperature is 800°C), calcinate for 5 hours, sieve after cooling to obtain geopolymer colloid powder; then add the homogeneous mixed solution obtained above to the above geopolymer Stir in the colloidal powder for 240s to obtain a geopolymer slurry, then pour, vibrate, and cure under natural conditions to obt...

Embodiment 2

[0036] In this embodiment, the preparation process of the waterproof polymer material is as follows:

[0037] Put 0.07 parts of modified nano-magnesium oxide and 0.08 parts of dispersant in 10 parts of water, stir for 240s, and then put it under the power of 700W for 0.5h to obtain a uniform mixed solution; then weigh 39 parts of fly ash, 26 Pour 10 parts of phosphorus slag, 10 parts of ordinary Portland cement, and 6 parts of sodium bentonite into the mixing pot, stir for 90 seconds to obtain the mixture particles, and then mix the obtained mixture particles, 0.01 parts of admixture, 5 parts of sodium hydroxide solid and Add 5 parts of sodium silicate solid into the muffle furnace (setting temperature is 900°C), calcinate for 6 hours, sieve after cooling to obtain geopolymer colloidal powder; then add the homogeneous mixed solution obtained above to the above geopolymer Stir in the colloidal powder for 120s to obtain a geopolymer slurry, then pour, vibrate, and maintain under...

Embodiment 3

[0039] In this embodiment, the preparation process of the waterproof polymer material is as follows:

[0040]Put 0.06 parts of modified nano-magnesium oxide and 0.08 parts of dispersant in 9 parts of water, stir for 240s, and then put it under the power of 700W for 0.5h to obtain a uniform mixed solution; then weigh 40 parts of fly ash, 26 Pour phosphorus slag, 10 parts of ordinary Portland cement, 7 parts of sodium bentonite into the mixing pot, stir for 90 seconds to obtain the mixture particles, then mix the obtained mixture particles, 0.01 parts of admixture, 4 parts of sodium hydroxide solid and Add 5 parts of sodium silicate solids into the muffle furnace (setting temperature is 800°C), calcinate for 5 hours, sieve after cooling to obtain geopolymer colloid powder; then add the homogeneous mixed solution obtained above to the above geopolymer Stir in the colloidal powder for 240s to obtain a geopolymer slurry, then pour, vibrate, and cure under natural conditions to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com