Glass fiber reinforced TPU material and preparation method thereof

A glass fiber and long glass fiber technology, which is applied in the field of glass fiber reinforced TPU materials and their preparation, can solve the problems of little research on injection molding characteristics and little in-depth research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

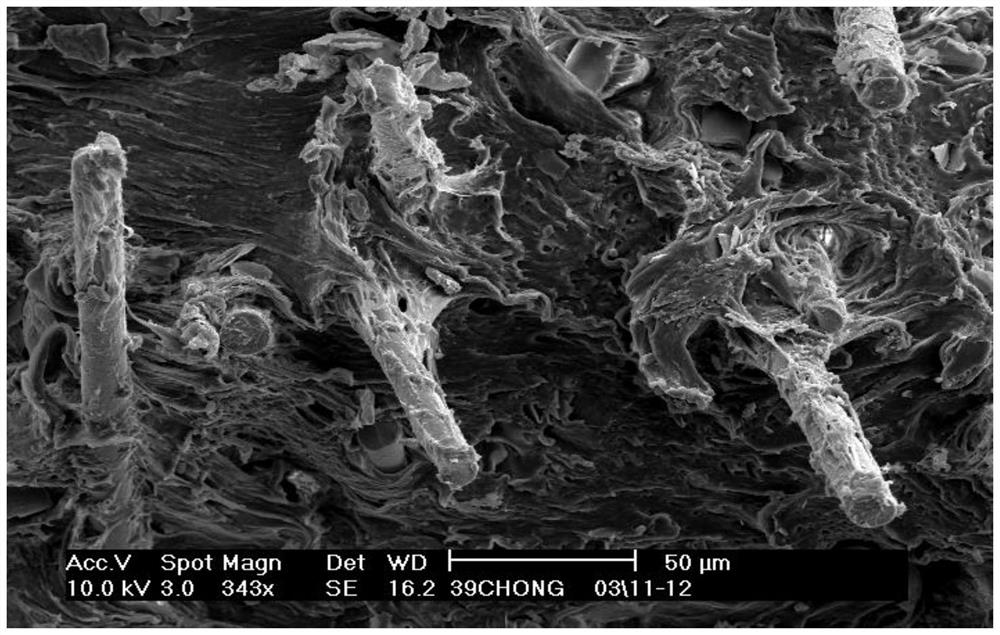

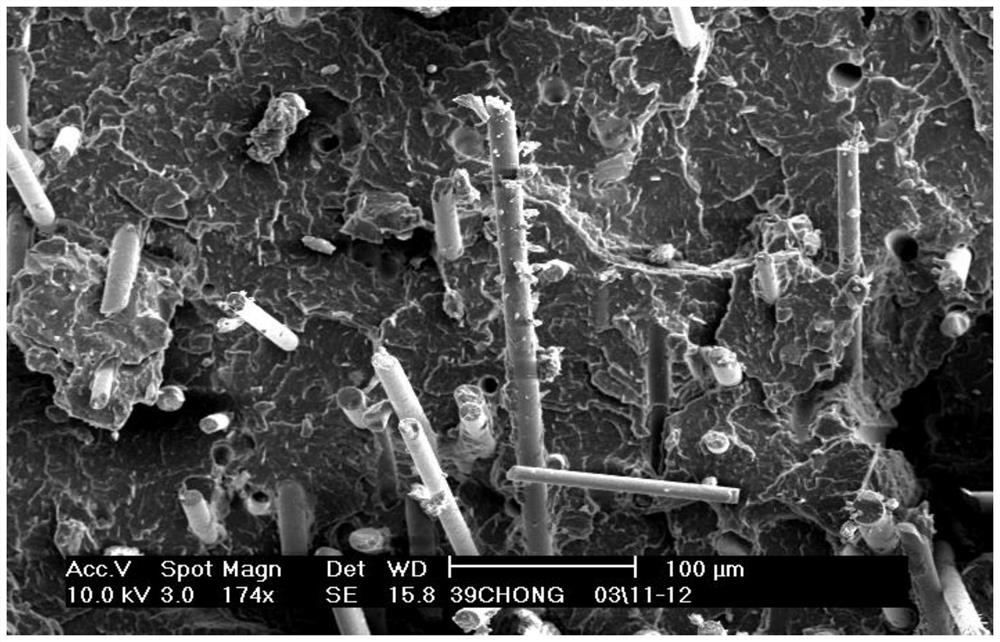

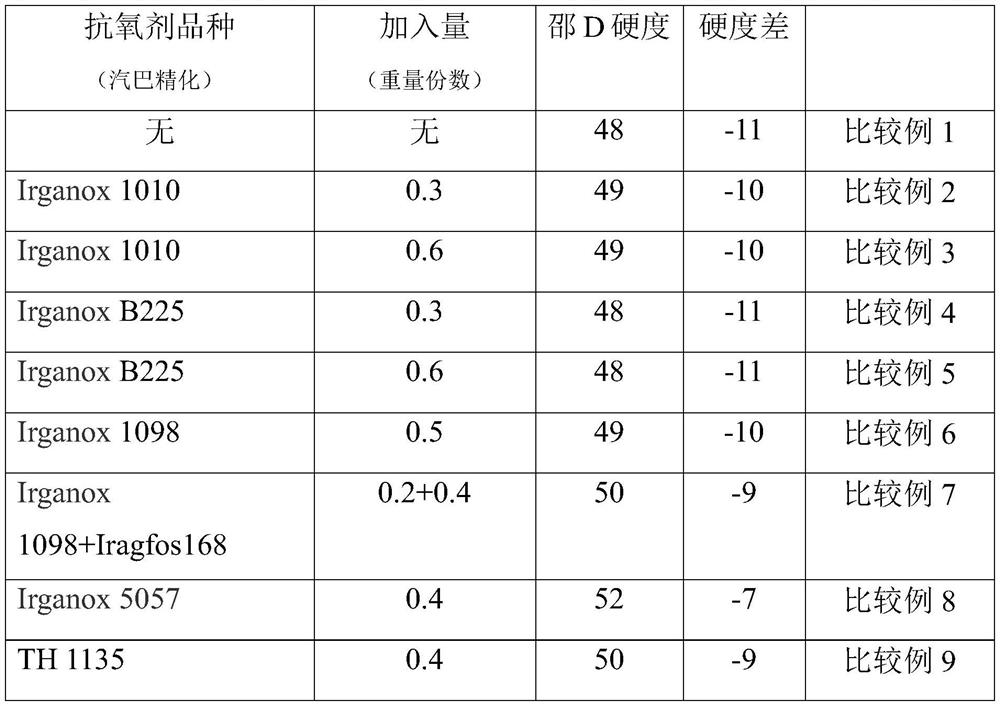

[0054] The preparation method of glass fiber reinforced TPU material includes: ① The polyurethane elastomer (Bayer, Germany, Desmopan365, Desmopan 392LE compounded in a weight ratio of 1:1) was dried in a cyclone drying oven at 100 °C for 4 hours. ②Put the dried polyurethane elastomer into the mixing tank, and add antioxidant (Ciba Specialty Chemicals, Irganox 5057 and TH 1135 in a weight ratio of 1:2) and toner (carbon black, U.S. Cabot Company, M570), warpage improving agent (glass fiber powder produced by Nanjing Glass Fiber Research Institute, 400 orders, and Guilin Guiguang Talc Development Co., Ltd. production, 400 order talcum powder, the two are by weight: 1:1 mixed and compounded), light stabilizer (BASF TINUVIN XT 855FF), mixed evenly. ③ Small test to determine the screw speed, feeding screw speed, number of glass fiber strands (Beijing Xingwang Glass Fiber Factory, 1000 type). ④ The screw temperature conditions of 180-190°C, the screw configuration of two sets of s...

Embodiment 2

[0062] From the performance test results of Example 1 and Example 2, it can be seen that whether the glass fiber surface is treated or not has almost no influence on the material performance. The present application has low requirements for glass fiber surface treatment, and untreated glass fiber can achieve the same effect, and the method of the present application can effectively reduce raw material costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com