Time sequence classification analysis method and system for glass quality influence factors

A technology of time series and influencing factors, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve problems such as energy consumption, impact, and reduction of oxygen content in the kiln

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

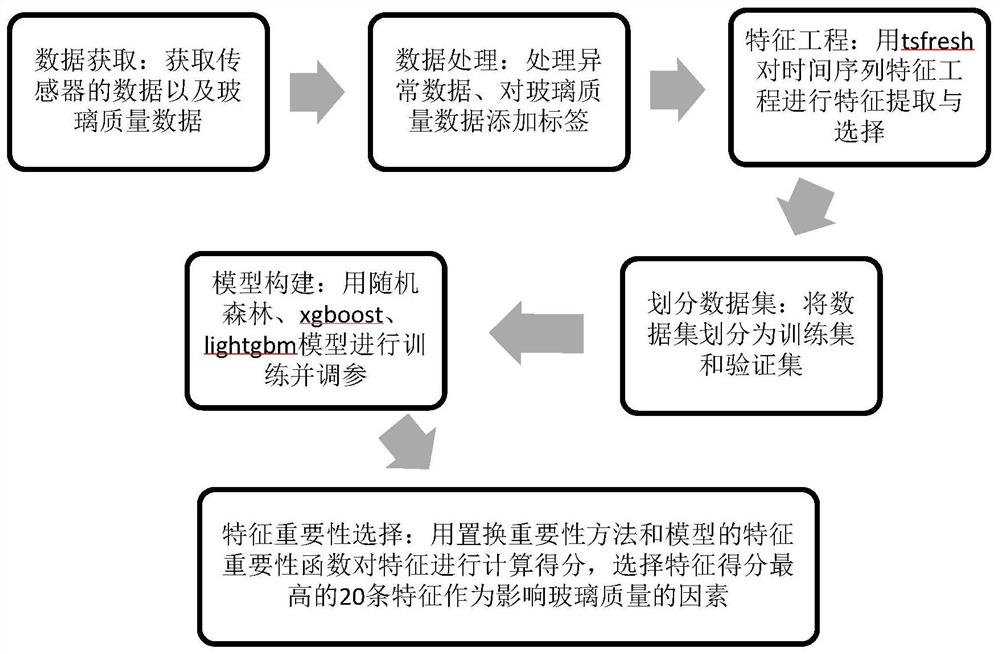

[0036] The invention can provide a model for time series classification and analysis of glass quality influencing factors. The present invention combines the machine learning model with the glass manufacturing process, analyzes and models time series data such as furnace temperature, pressure, natural gas flow, oxygen flow, and pressure, and finds key factors that affect glass quality, thereby improving glass quality. Production yield. The random forest algorithm and tree-based integrated model xgboost and lightgbm models of the present invention classify time series data and glass quality data. The tree-based model will split each feature in the classification process, and find the optimal split point to generate a tree, so as to realize the classification of time series. At the same time, after the three models are traine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com