A processing method for extruding taps

A technology for extruding taps and processing methods, which is applied to metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of complicated processing operations of extruding taps, inability to effectively realize one-time processing of threads and thread outer circles, etc. To achieve the effect of simple structure, simple installation and layout, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

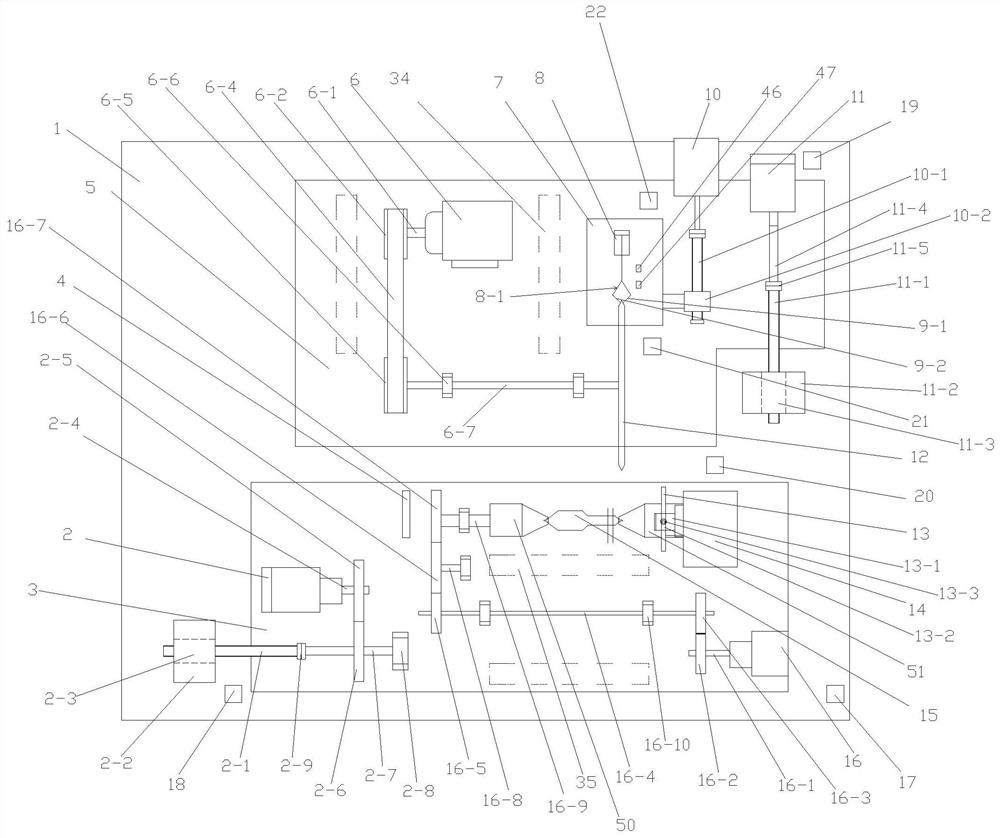

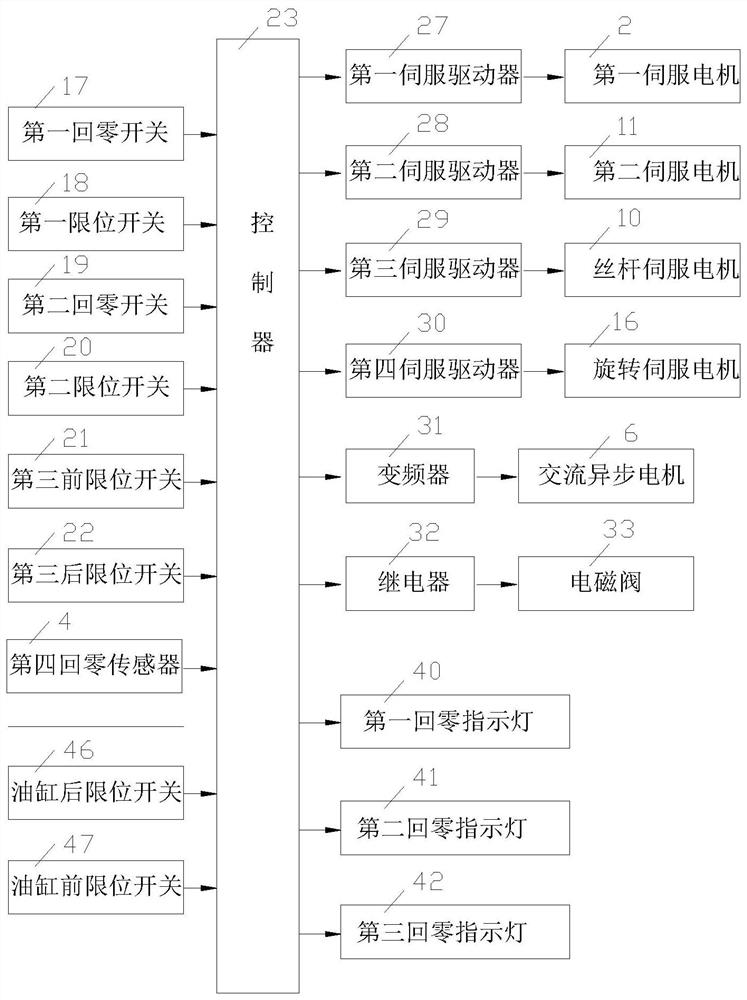

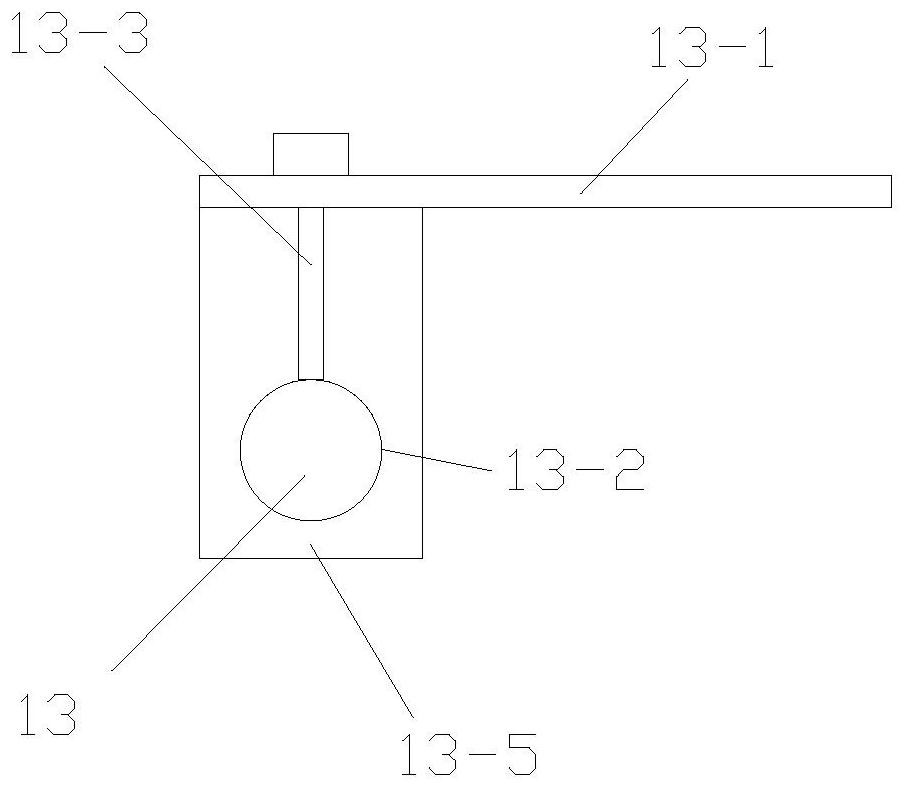

[0193] like Figures 1 to 7 A process of pressing a squeezing tap, the extruded tap of pressing, including a bed base 1, a longitudinal slip mechanism and a transverse slip mechanism disposed on the bed base 1, and provided in the A rotation mechanism and rotation of the workpiece 15 and the rotation of the workpiece 15 and the grinding wheel trimming mechanism disposed on the lateral sliding mechanism and a monitoring module disposed on the bed base 1;

[0194] The longitudinal slip mechanism includes a longitudinal guide rail 35 disposed on the bed base 1, a longitudinal slide 3 mounted on the longitudinal guide rail 35 and a longitudinal slide module that drives longitudinal slide 3 pulling along the longitudinal guide rail 35;

[0195] The lateral sliding mechanism includes a transverse rail 34 disposed on the bed base 1, a transverse slide 5 mounted on the transverse guide rail 34 and a lateral drive module that drives the transverse slide 5 along the transverse guide rail 34;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com