Low-shrinkage halogen-free flame-retardant polyethylene composition and preparation method and application thereof

A flame-retardant polyethylene and low-shrinkage technology, which is applied in the direction of plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problems of low shrinkage mechanical strength and the inability to improve the shrinkage rate and mechanical properties of polyethylene materials at the same time. Achieve low molding shrinkage and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

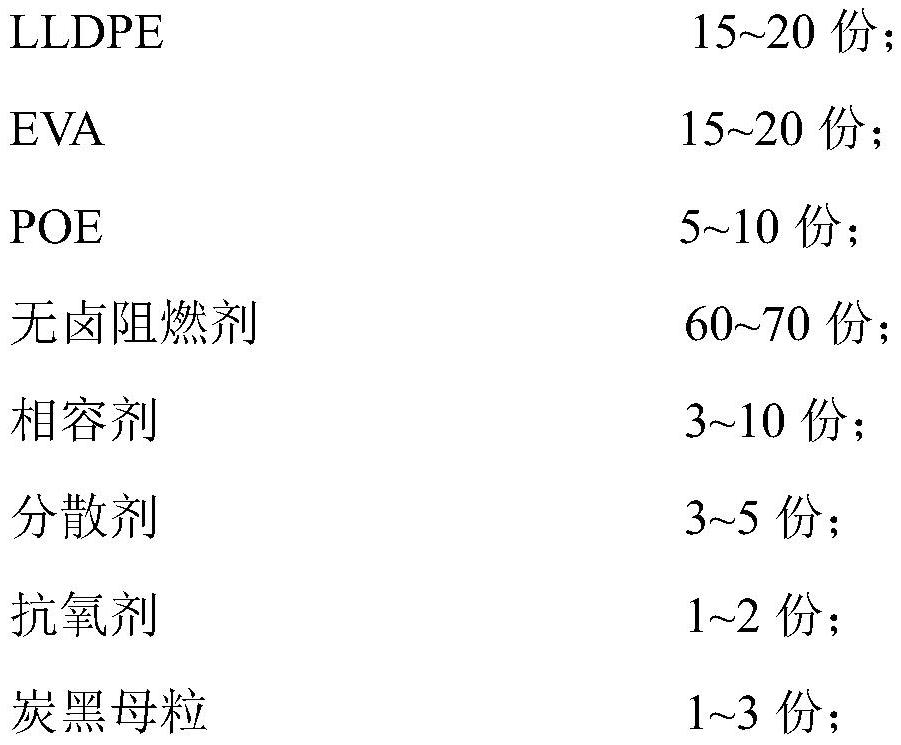

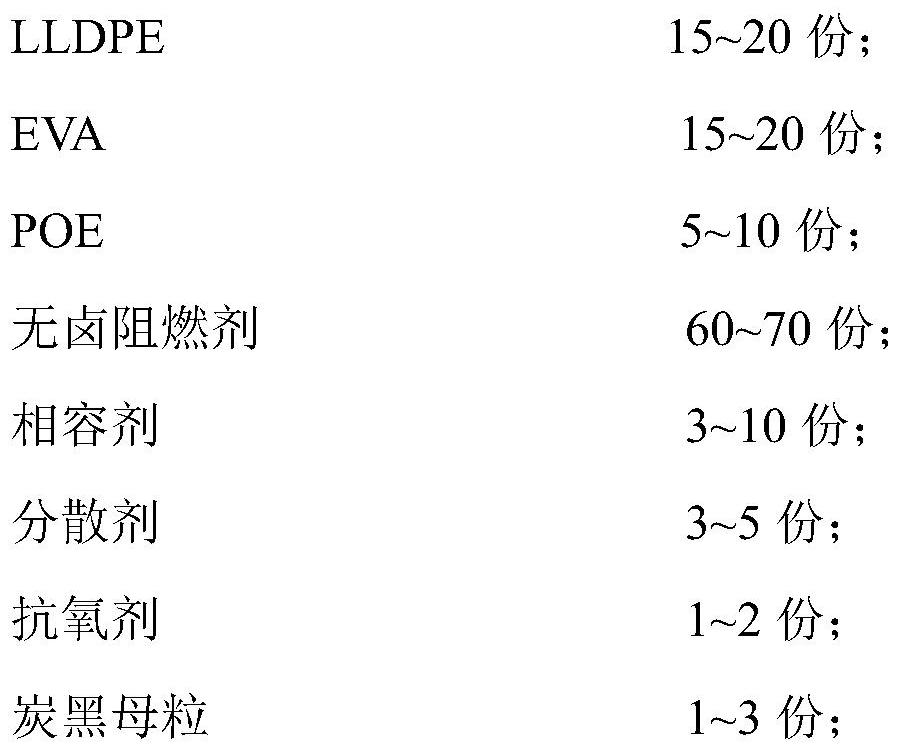

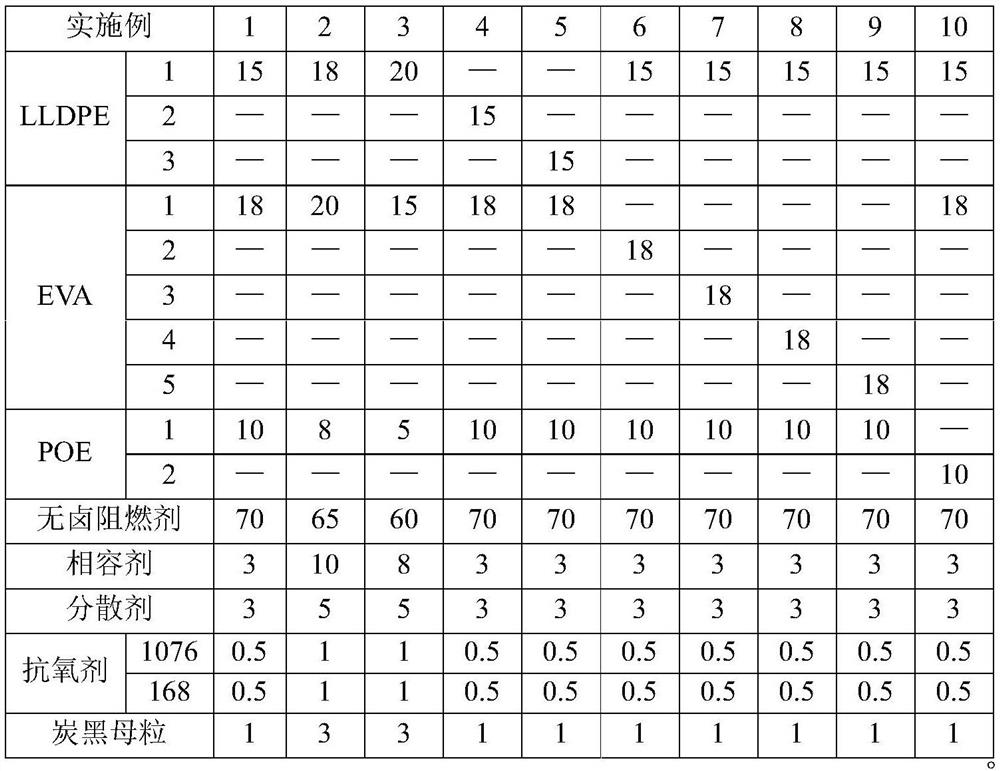

[0055] According to the formula in Table 1, add LLDPE, EVA, POE, halogen-free flame retardant, compatibilizer, dispersant, antioxidant, and carbon black masterbatch into the high-speed mixer, and mix at a speed of 2000-3000rpm Obtain the mixture evenly; put the mixture into a twin-screw extruder for melt blending, extruding, and granulation to obtain the low-shrinkage halogen-free flame-retardant polyethylene composition, wherein the twin-screw extruder The temperature is 180-200°C, and the length-to-diameter ratio of the screw is 48:1.

[0056] Table 1 each embodiment each component content (weight part)

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com