Process for producing clostridium butyricum through high-density fermentation under negative pressure condition and application

A Clostridium butyricum, production process technology, applied in the direction of microorganism-based methods, bacteria, microorganisms, etc., can solve the problems of insufficient anaerobic conditions, complex operation, low content of live bacteria per unit of bacteria powder, etc., to achieve the promotion of proliferation and Sporulation, alleviating feedback inhibition, and promoting growth effects

Active Publication Date: 2021-05-07

INST OF MICROBIOLOGY JIANGXI ACADEMY OF SCI +1

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Existing clostridium butyricum anaerobic fermentation process has the following defects: (1) the traditional method of removing oxygen in the fermentation system mainly includes boiling method, air isolation method (covering liquid paraffin), adding reducing agent, feeding methods such as nitrogen, In actual industrial production, the operation is complicated, and it is easy to leave a small amount of oxygen to cause insufficient anaerobic conditions; (2) a large amount of compound culture medium or a large amount of poorly water-soluble components are used as the culture medium, which causes post-processing difficulties and

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

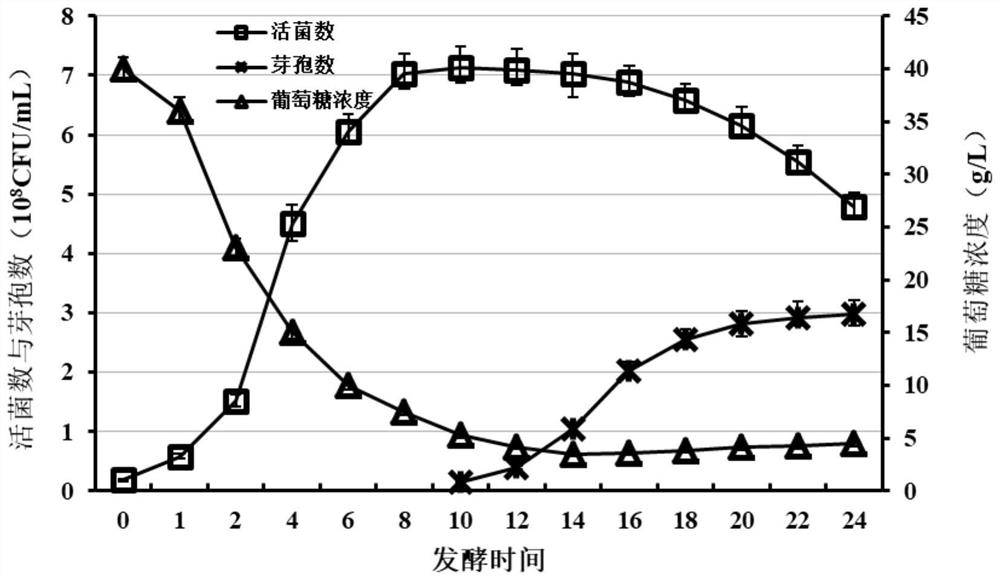

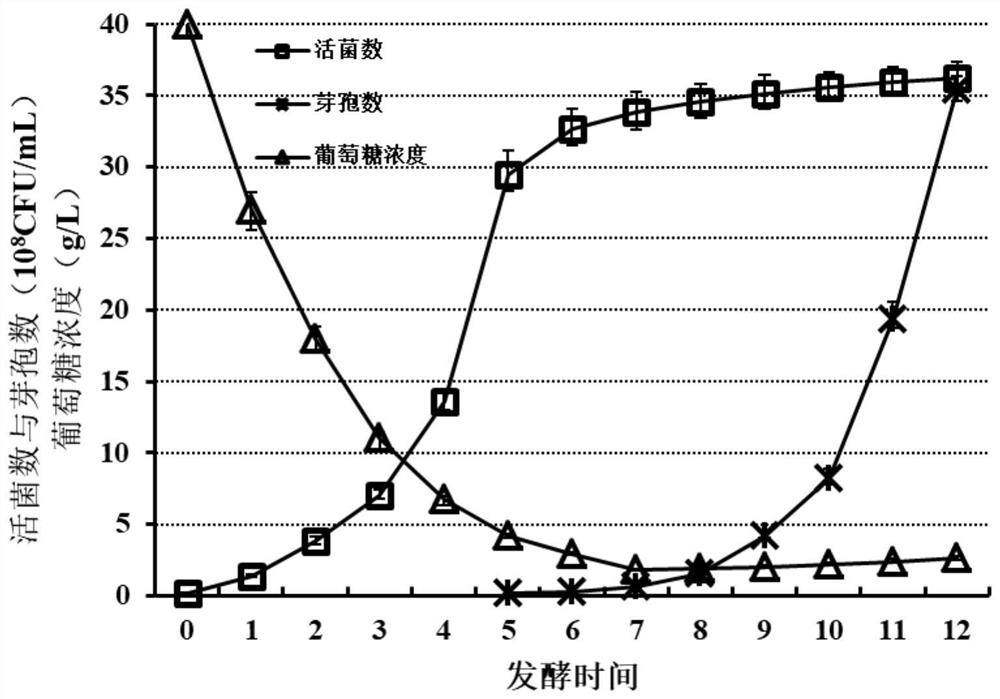

The invention relates to a process for producing clostridium butyricum by high-density fermentation under a negative pressure condition. The process comprises the following steps of inoculating a clostridium butyricum seed solution into a fermentation culture medium, carrying out anaerobic fermentation under the conditions that the temperature is 35-40 DEG C, the stirring rotating speed is 100-300r/min, the pH value is constant to 6.0-7.5 by using soluble alkali, and the vacuum degree is kept to 0.03-0.08 Mpa under negative pressure air exhaust, culturing for 10 hours, and ending the fermentation. Vacuum is maintained through negative-pressure air exhaust, and stirring is started, a strict anaerobic environment is created, and a fermentation medium and a fed-batch fermentation process are optimized based on amino acid characteristics of clostridium butyricum thalli and spores, so that accumulation of metabolic harmful substances is reduced to the maximum extent, proliferation of clostridium butyricum and spore transformation are promoted, and the number of spores in the obtained clostridium butyricum fermentation liquor reaches 7.9 billion CFU/mL or above. The process for producing the clostridium butyricum through fermentation has the advantages that inert gas does not need to be introduced, the fermentation period is short, post-treatment is simple, the production cost is greatly reduced on the whole, the spore number of clostridium butyricum clear liquid fermentation is greatly increased, and meanwhile the clostridium butyricum with high cost performance can be produced.

Description

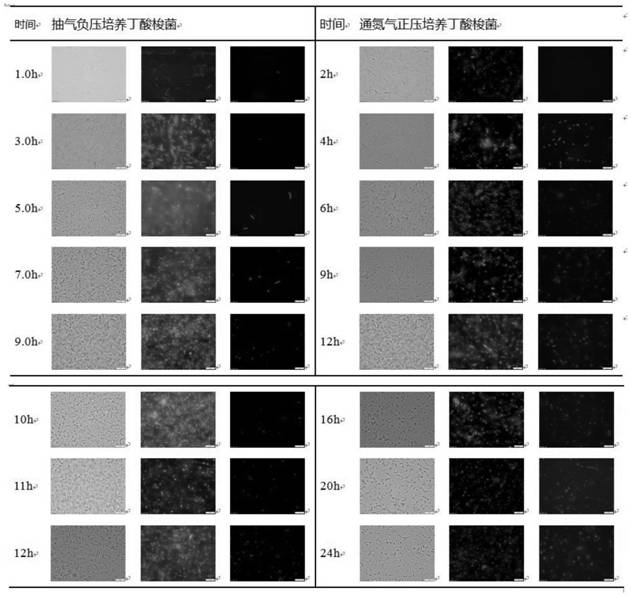

technical field [0001] The invention relates to the field of microbial fermentation engineering, in particular to a Clostridium butyricum fermentation process technology, and more specifically to a high-density fermentation production process and application of Clostridium butyricum under negative pressure conditions. Background technique [0002] Clostridium butyricum (Clostridium butyricum), also known as butyric acid bacteria, Clostridium butyricum, and Miyaribacterium, is an anaerobic probiotic that exists in the intestines of animals, as well as in soil, natural yogurt, and cheese. Clostridium genus in the Clostridium family of Firmicutes, the thallus is fusiform and straight rod-shaped, with flagella all over the body, and has certain fluidity; endogenous spores are eccentric and terminal, spherical or oval in shape, and have gastric acid resistance , bile resistance and other characteristics, can pass through the stomach and small intestine, and reach the completely a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C12N1/20C12N1/04C12R1/145

CPCC12N1/20C12N1/04Y02E50/10

Inventor 郭建军袁林曾静聂俊辉王通

Owner INST OF MICROBIOLOGY JIANGXI ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com