Dyeing and finishing process of all-cotton edible wool knitted fabric

A wool knitting and fabric technology is applied in the dyeing field of anti-wrinkle finishing of knitted fabrics, which can solve the problems of stiffness and easy hand feeling of the cloth, and achieve the effects of reducing dosage, shortening reaction time and reducing erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The used fabric to be dyed in this embodiment is that the fabric to be dyed is 40SJC+30D spandex single jersey, 420 kilograms, and the dyeing equipment used is an air flow dyeing machine; the dyeing bath ratio is 1:4;

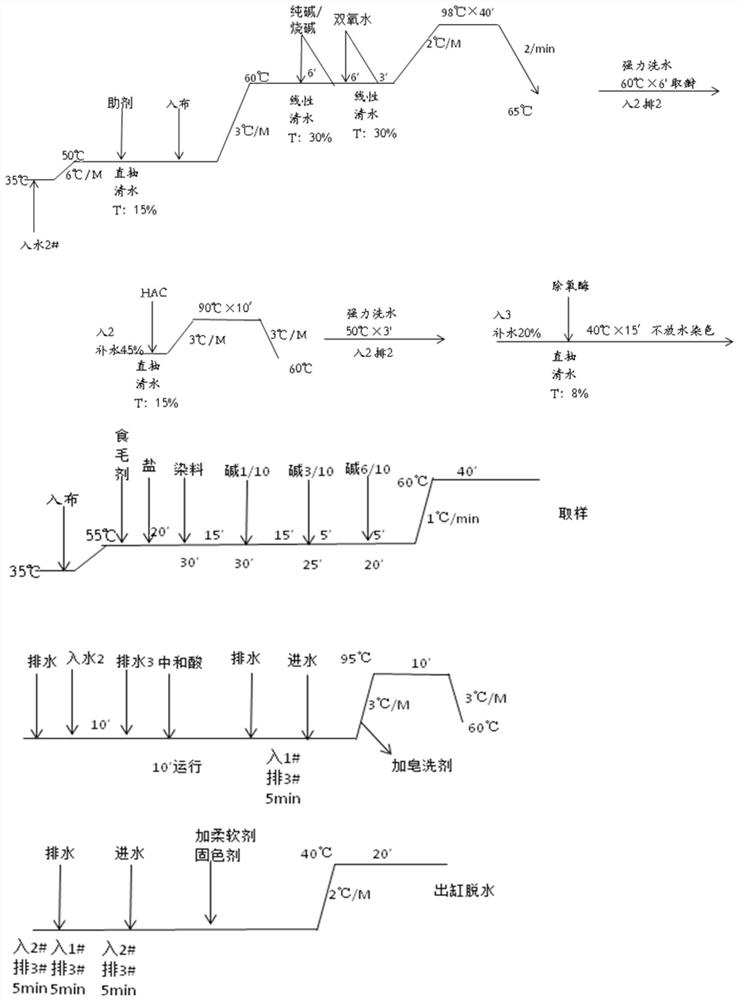

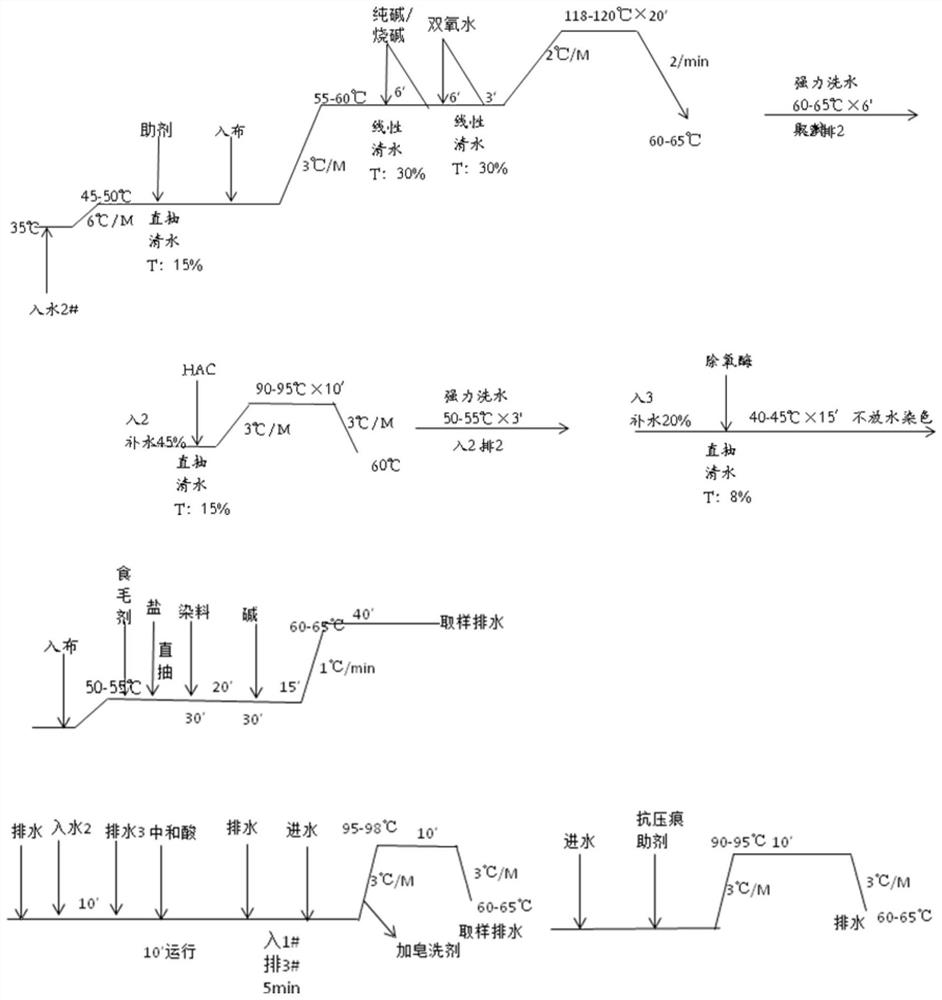

[0033] Such as figure 2 As shown, the specific steps are as follows:

[0034] (1) Add degreaser to the dyeing bath, add the fabric to be dyed into the water bath, heat up to 55-60°C, add soda ash, caustic soda, hydrogen peroxide, hydrogen peroxide stabilizer, and gradually heat up to 118-120°C for 20 minutes, Cool down to 60-65°C.

[0035] (2) Neutralize at room temperature, heat up to 90-95°C for soaping for 10 minutes, then cool down to 60-65°C for washing. Re-introduce water and add deoxygenase, incubate at 40-45°C for 15 minutes before staining.

[0036] (3) Add water to the treated fabric to be dyed to the specified bath ratio, then heat up to 50-55°C, add high-efficiency wool-eating agent, all sodium sulfate, and dyes, add soda ash after 20 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com