Manufacturing method of main rope of plastic-coated water skiing rope

A production method and plastic-coating technology, which can be used in transportation and packaging, textiles, fabrics, etc., and can solve problems such as performance optimization of the main rope of the water skiing rope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

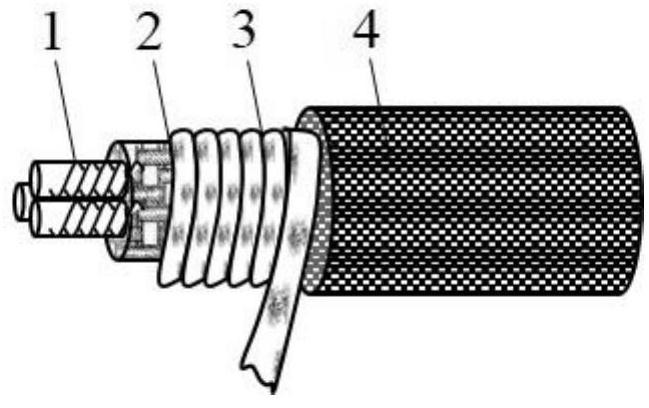

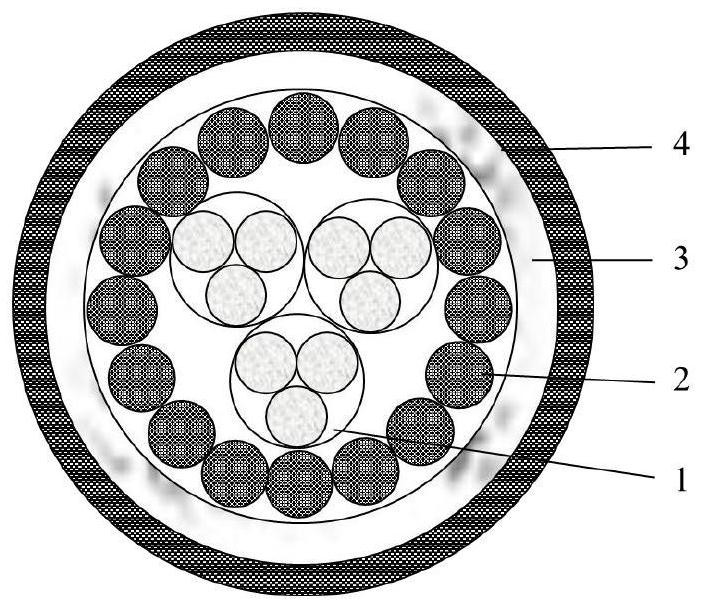

[0039] A main rope of a plastic-coated water skiing rope and a manufacturing method thereof, comprising the following steps:

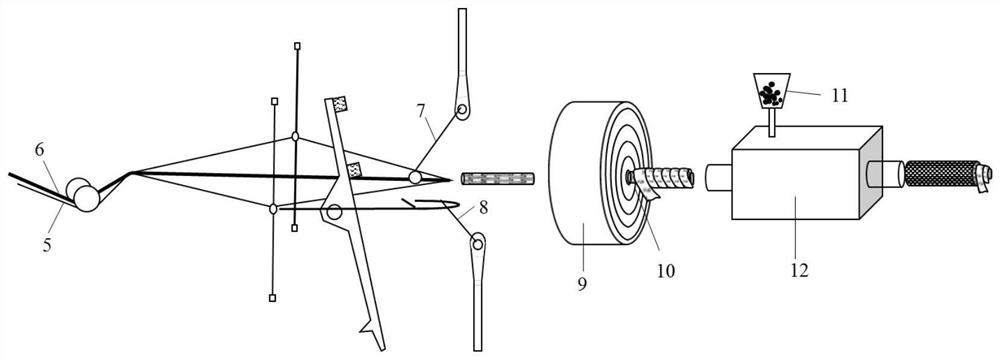

[0040] (1) Take 3 ultra-high molecular weight polyethylene filaments with a specification of 1000D, twist and combine them into one yarn on a ring twister, the twist direction is Z direction, and the twist is set to 20 twists / meter to make warp yarn 5.

[0041] (2) Get 16 warp yarns that above-mentioned step (1) obtains, arrange on the loom in parallel, get two 250D ultra-high molecular weight polyethylene multifilaments without twisting, as weft yarn 7 and overlock thread 8 respectively. Through the opening and closing movement of the loom and the reciprocating movement of the weft yarn, the warp yarn 5 and the weft yarn 7 are interwoven to form a closed structure, and the overlock thread 8 is trimmed on one side to obtain a non-sandwich woven rope with a linear density of 5.7 g / m.

[0042] (3) Import the non-sandwich woven rope index obtained in step...

Embodiment 2

[0045] A main rope of a plastic-coated water skiing rope and a manufacturing method thereof, comprising the following steps:

[0046] (1) Take 3 ultra-high molecular weight polyethylene filaments with a specification of 800D, twist and combine them into one yarn on a ring twisting machine, the twist direction is Z direction, and the twist is set to 20 twists / meter to make warp yarn 5.

[0047] (2) Take a single filament of ultra-high molecular weight polyethylene with a specification of 1600D and twist it on a ring twisting machine. The twist is set to 20 twists / meter, and the twist direction is Z or S direction, and the twisted filament is used as a rope core 1.

[0048] (3) Get 16 warp yarns that the above step (1) obtains, 4 S direction rope cores that step (2) obtains and 4 Z direction rope cores are arranged in parallel, introduce on the loom, get two 250D ultra-high molecular weight Polyethylene multifilaments are not twisted, and are used as weft yarn 7 and overlock th...

Embodiment 3

[0052] A main rope of a plastic-coated water skiing rope and a manufacturing method thereof, comprising the following steps:

[0053] (1) Take 3 ultra-high molecular weight polyethylene filaments with a specification of 800D, twist and combine them into one yarn on a ring twisting machine, the twist direction is Z direction, and the twist is set to 20 twists / meter to make warp yarn 5.

[0054] (2) Take 5 ultra-high molecular weight polyethylene filaments with a specification of 800D, and carry out preliminary twisting on a ring twister to form a yarn, the twist is set to 40 twists / meter, and the twist direction is S direction; take three to complete the initial The twisted yarn is re-twisted on the ring twister, the twist is 20 twists / meter, and the twist direction is Z direction, and three twisted yarns 6 are made as the rope core 1.

[0055] (3) Get 16 warp yarns obtained in the above step (1), and 1 rope core obtained in the step (2), arrange them in parallel, and introduce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com