Drilling methane self-circulation blasting fracturing enhanced extraction method

A detonation fracturing and methane technology, applied in earthwork drilling, mining fluid, measurement, etc., can solve problems such as uneven mixing, methane detonation range and effect limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

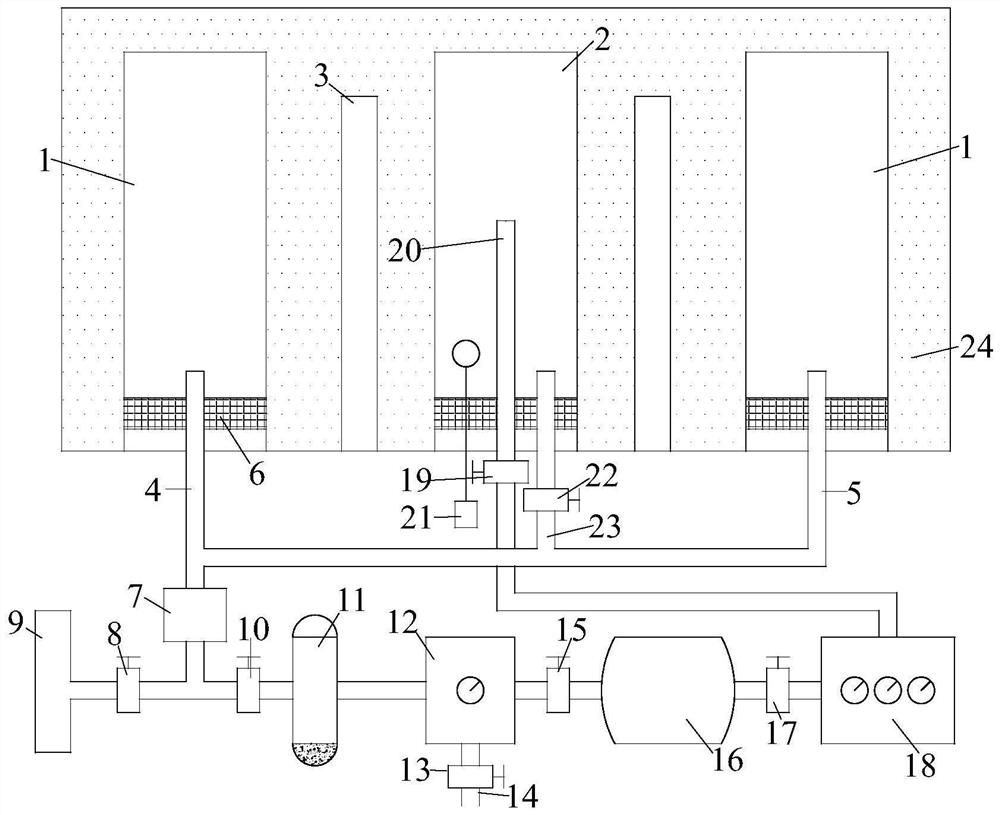

[0021] Below in conjunction with the implementation in the accompanying drawings, the present invention will be further described:

[0022] The drilling methane self-circulation explosion fracturing enhanced drainage method of the present invention, the specific steps are as follows:

[0023] a. First construct two gas drainage boreholes 1, one explosion fracturing borehole 2 and two guide boreholes 3 from the roadway to the coal seam, and then install the gas drainage pipe 1 4 and the gas drainage pipe 2 5 respectively Put into the gas drainage borehole, put the gas drainage pipe 3 23, the gas injection pipe 20 and the ignition device 21 into the explosion fracturing drilling, and finally seal the gas drainage drilling and the explosion fracturing drilling;

[0024] b. Connect gas extraction pipe 1 4, gas extraction pipe 2 5, and gas extraction pipe 3 23 to the suction port of gas extraction pump 7 through pipelines, and gas injection pipe 20 to exit gas booster pump 18 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com