Marker selection method for oil field logging

A marker and well logging technology, which is applied in the directions of measurement, earthwork drilling, wellbore/well components, etc., can solve the problems of crawler resistance, casing deformation, manpower, and high replacement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] The general procedure for testing the fluid production profile of a horizontal oil well is as follows.

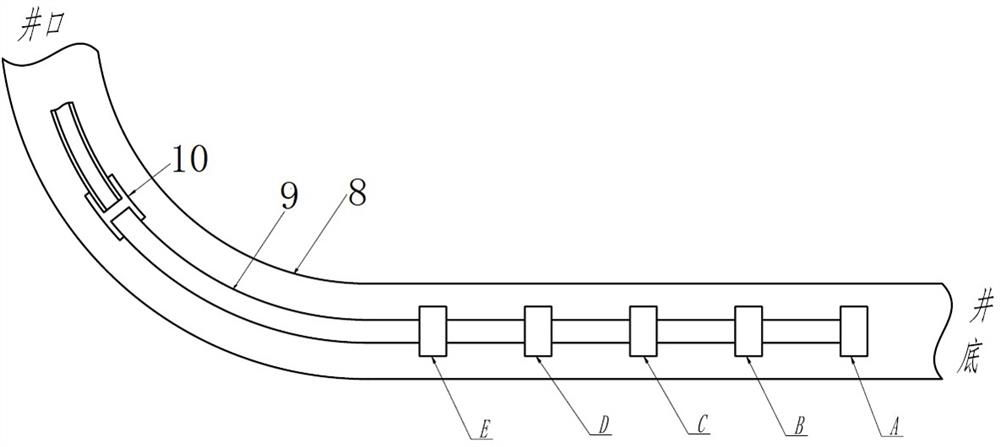

[0098] 1) Design of downhole release device deployment plan: determine which downhole fluid production conditions should be paid attention to according to well conditions, and count the number of layers and the specific positions of the front and rear ends of each layer (near the bottom of the well is the front end, and away from the bottom of the well for the backend). A release device is to be deployed at the back end of each concerned interval, and the number of concerned intervals is the number of release devices that need to be deployed. Such as figure 2 As shown, for example, it is necessary to measure 5 intervals, and it is necessary to deploy 5 release devices to the back end of each interval.

[0099] 2) Factory production: According to the above, it is necessary to measure the liquid production of 5 layers, first form 5 kinds of solid oil-based markers a...

Embodiment 2

[0109] Example 2 Water-seeking test for high water-cut level oil wells

[0110] For high water-cut wells, if there is still a small amount of oil production, it is necessary not only to find out the main water-production interval, but also to find the oil-production interval. The traditional water-seeking test method mainly focuses on the main water-producing layer, but in reality, if the main water-producing layer is accompanied by a small amount of oil production, then the main water-producing layer is blocked according to the test conclusion, and the result may be water plugging It stopped, and a small amount of oil was also blocked. Therefore, if the main oil-producing section of the well can be given at the same time as the main water-producing section, it will provide more comprehensive basic data for the subsequent comprehensive management.

[0111] Such as figure 2 As shown, for a high water-cut horizontal well with 5 intervals, it is planned to deploy 5 release dev...

Embodiment 3

[0116] Example 3 Full life cycle production monitoring of horizontal wells

[0117] For horizontal oil wells, the technology of this patent application can be used to implement the production monitoring of the entire life cycle, that is, to monitor the liquid production of each section of the horizontal well, including the flow rate of each section, the ratio of oil to water, and as the production progresses, the production layer trend of change. Mastering this information at any time will provide complete basic data for the scientific decision-making of production management and maintenance programs of horizontal wells.

[0118] Such as figure 2As shown, a horizontal well that has just been completed, or a horizontal well that has been in production for many years, has a total of 5 intervals. It is necessary to monitor the fluid production of each interval for a long time. At the back end of each interval ( A release device is deployed on the layer away from the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com