Drainage device for open pit mine

A technology for drainage devices and open pit mines, applied in mining devices, drainage, pump devices, etc., can solve the problems of increasing the electric energy of centrifugal pumps, time-consuming and laborious, and increasing the load of centrifugal pumps, so as to avoid obstruction of drainage, reduce electric energy, and reduce The effect of the probability of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

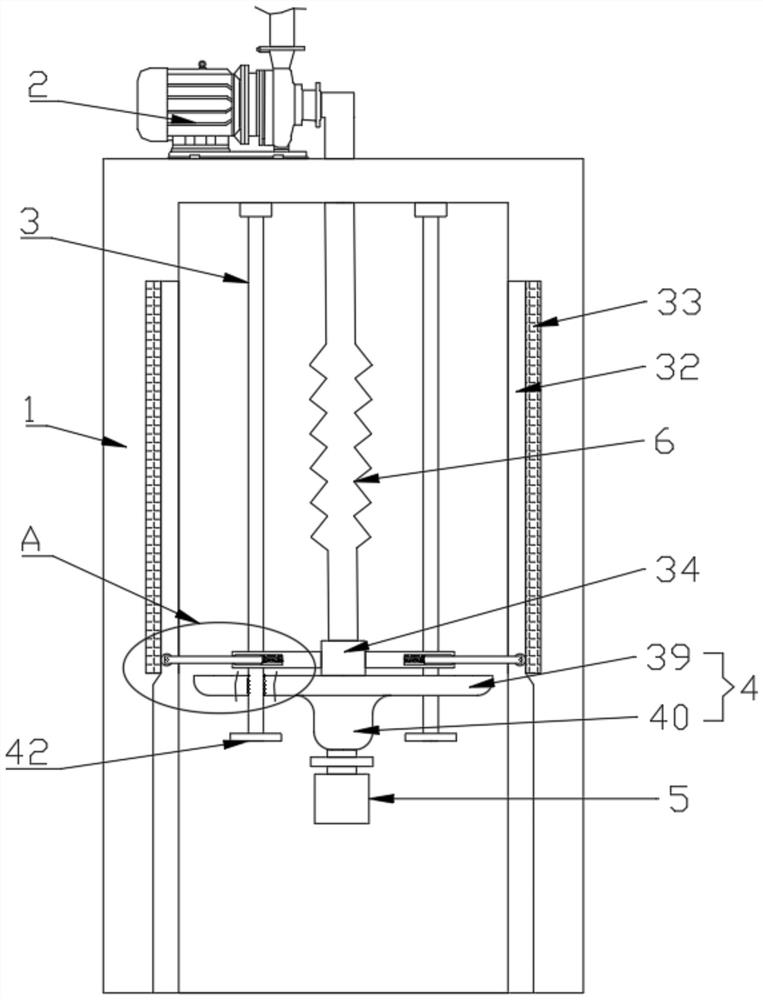

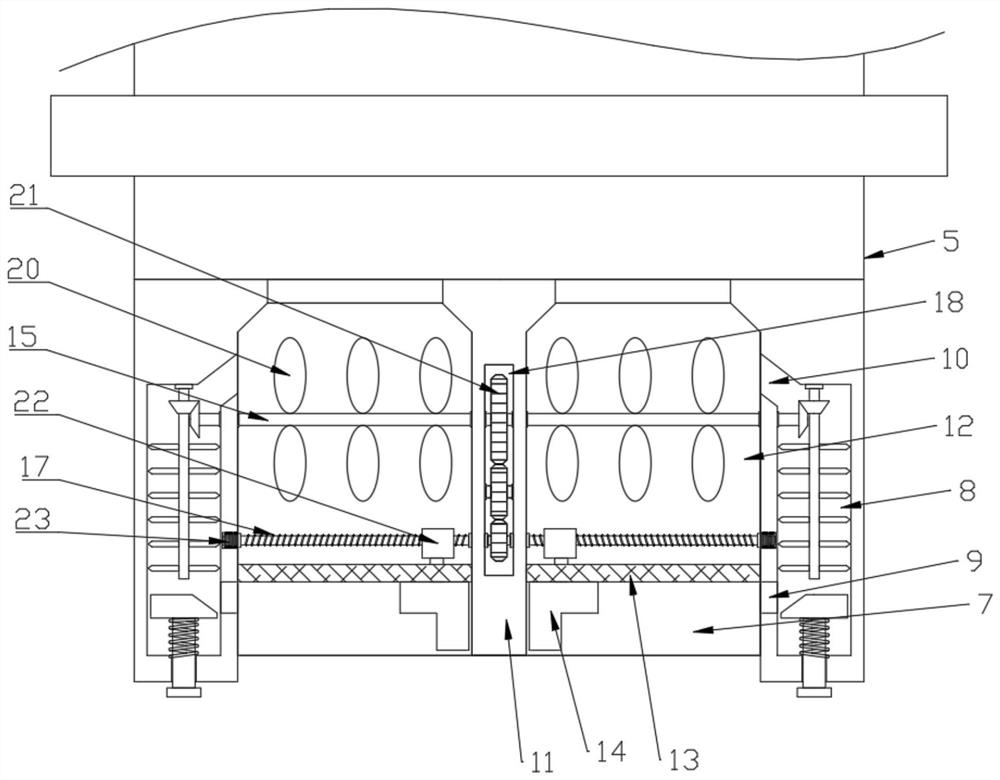

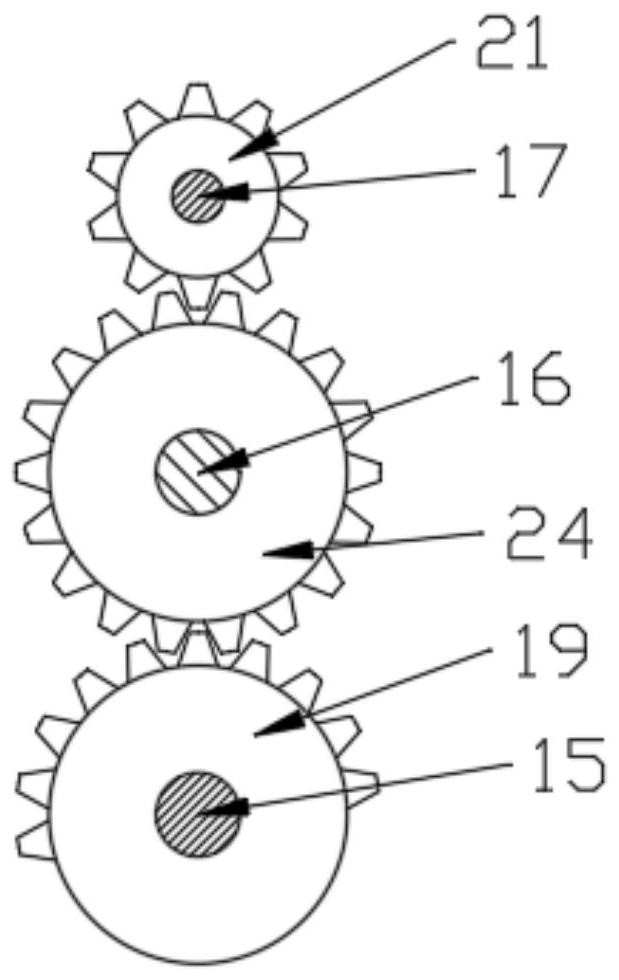

[0025] see Figure 1-5 , a drainage device for open-pit mines, including a mounting frame 1 installed in the open-pit mine water tank and a centrifugal pump 2 arranged on the mounting frame 1, the top surface of the inner wall of the mounting frame 1 is fixedly provided with two slide bars 3, A floating body 4 is movably installed on the slide bar 3, and the bottom of the floating body 4 is fixedly provided with a fixed box 5, and the top of the fixed box 5 is connected with the input end of the centrifugal pump 2 through a flexible hose 6, and the fixed box There is a groove 7 in the bottom end surface of the box 5, and the bottom end surface of the fixed box 5 is located on both sides of the groove 7, and a slag discharge groove 8 is symmetrically provided. The slag discharge port 9 and the connection port 10, and a crushing assembly is provided in the slag discharge tank 8, and a vertical partition 11 is fixed in the groove 7, and the groove 7 is divided into two by the par...

Embodiment 2

[0032] This embodiment expands the functions on the basis of Embodiment 1, specifically:

[0033] The inner surface of the installation frame 1 is symmetrically provided with a chute 32, the chute 32 is embedded with a conductive plate 33 connected in series with the centrifugal pump 2, and the top of the floating body 4 is provided with a conductive plate 33 for both sides. Electrically connected connection assembly, the connection assembly includes a sleeve block 34 and connection units arranged on both sides of the sleeve block 34, the sleeve block 34 is sleeved on the telescopic hose 6, and the sleeve block 34 is connected to the top surface of the floating body 4 Fixedly connected, the connecting unit includes a telescopic sleeve 35, a telescopic rod 36 and an induction roller 37, the telescopic sleeve 35 is fixedly connected with the cover block 34, and one end of the telescopic rod 36 is rotatably connected with an induction roller 37, and the telescopic rod The other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com