A ramjet plasma igniter

A ramjet and plasma technology, applied in ramjet engines, machines/engines, mechanical equipment, etc., can solve the flight conditions that are not suitable for large airspace, high speed, and ultra-long distance, and it is difficult to solve the problem of continuous and stable combustion of ignition performance. Meet the requirements of wide-area ignition of the engine, and achieve the effect of widening the working boundary, stabilizing the speed of the combustible gas mixture, and being safe, reliable and wide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

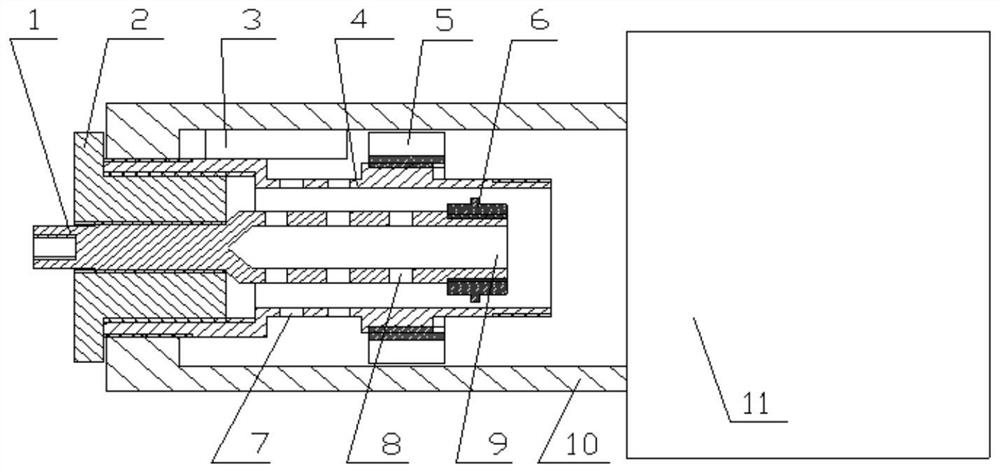

[0023] The present invention provides a ramjet plasma igniter, such as figure 1 As shown, it includes a high voltage electrode 1 , an insulating medium 2 , a low voltage electrode 4 , a rectifier grid 5 , a discharge boss 6 , an annular casing 10 , and a flame nozzle 11 . The insulating medium 2 is made of polytetrafluoroethylene.

[0024] The low-voltage electrode 4 is fixed on the outer circumference of the high-voltage electrode 1 through the insulating medium 2, and a discharge space is formed between the high-voltage electrode 1 and the low-voltage electrode 4; the insulating medium 2 is used to isolate and support the high-voltage electrode 1 and the low-voltage electrode 4. One end of the annular casing 10 is fixed on one end of the outer circumference of the low-voltage electrode 4, and the other end is fixedly connected with the flame nozzle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com