Digitized intelligent tensioner for pumping unit belt

A technology of pumping unit and tensioner, applied in the direction of belt/chain/gear, mechanical equipment, program control in sequence/logic controller, etc., can solve the belt slippage of pumping unit, difficult management, fire accidents, etc. problems, to achieve the effect of reducing the probability of shutting down production and wells, reducing hidden risks, and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

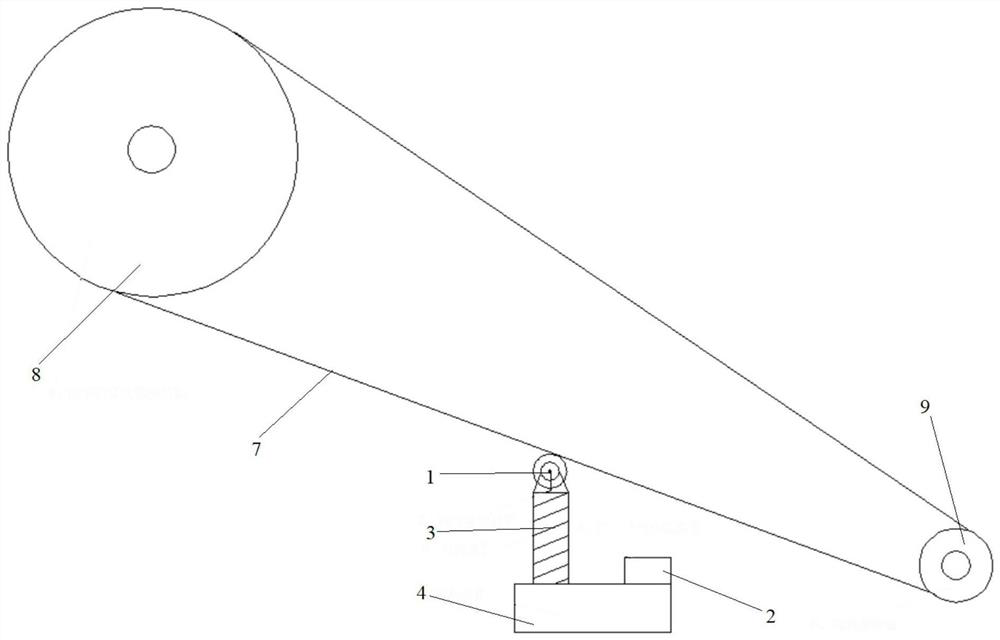

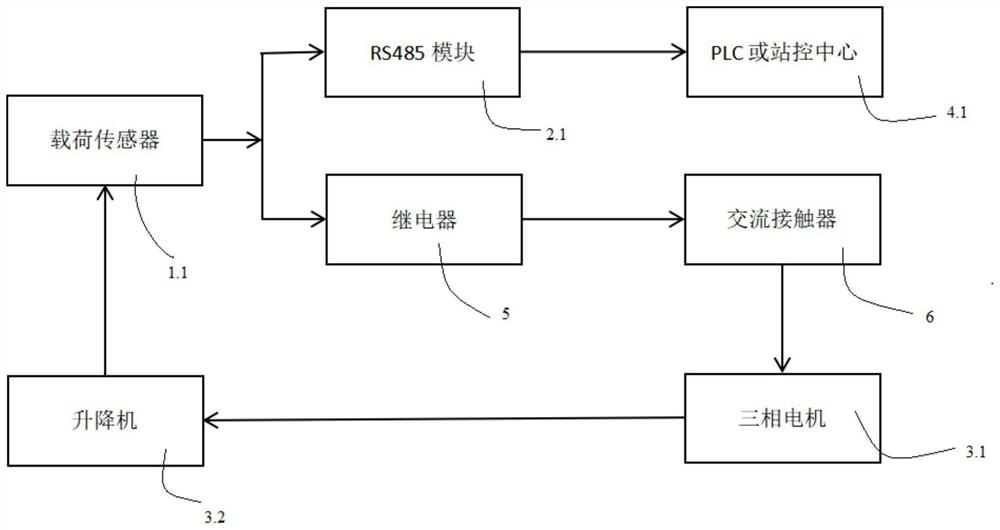

[0017]By the followingfigure 1 with2Further detailed description of the invention.

[0018]An oil tensioner belt digitized intelligent tensioner, including the contact monitoring unit 1, the signal transmission unit 2, the lifting portion 3, and the control module 4, and the contact monitoring unit 1 is used to monitor the tightness of the belt, and the signal transmission unit 2 is used. The signal monitored by the contact monitoring unit 1 is transmitted to the control module 4, and the lifting portion 3 is used to adjust the looseness of the belt; wherein the contact control unit 1 includes a load sensor 1.1, the signal transmission unit 2 includes an RS485 module 2.1, a lifting portion 3 includes a motor 3.1, an elevator 3.2 that is axially attached to the motor 3.1.

[0019]The looseness control device used in the prior art for the control of the belt of the beam pumping machine is generally a single structure, and it is not possible to achieve timely and accurate operations for diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com