Exhaust and leak hunting structure of T-MAP sensor gland and sealing method

A sensor and gland technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum for liquid tightness measurement, etc., can solve the problems of unfavorable product use safety, rust, high risk of leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below according to the drawings and embodiments.

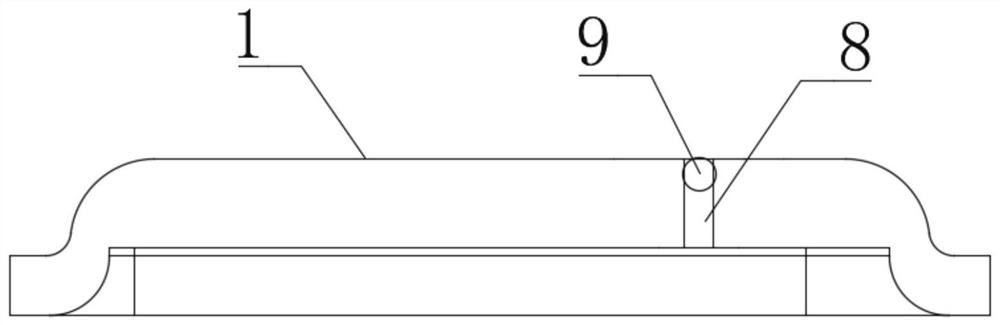

[0030] Such as figure 1 As shown, as the exhaust and leak detection structure of the traditional T-MAP sensor gland, an air outlet 8 is punched on the gland body 1. After the exhaust and leak detection are completed, a diameter ratio The steel ball 9 with a slightly larger diameter of the air outlet hole 8 is directly riveted into the air outlet hole 8 , thereby achieving the purpose of sealing the air outlet hole 8 .

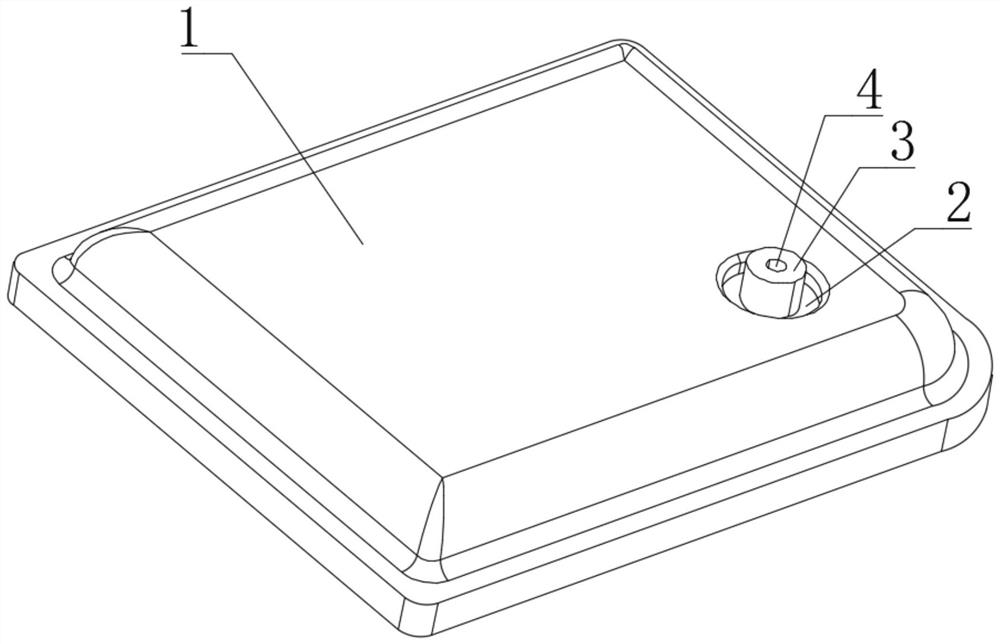

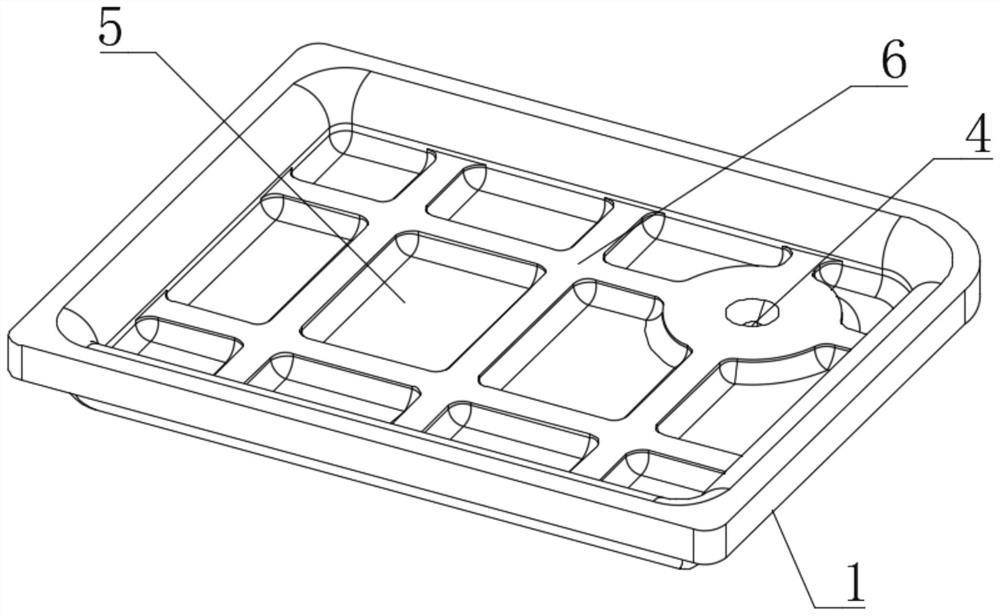

[0031] As an improvement on traditional structures such as Figure 2-4 As shown, a T-MAP sensor gland exhaust and leak detection structure, including a gland body 1, along the surface of the gland body 1 is provided with a circular groove 2, along the circular groove 2 The center of the circle is provided with a cylinder 3 perpendicular to it, along the central axis of the cylinder 3 there is a cylindrical air hole 4 that can pass through the gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com