A flow channel design method for a high-efficiency hydraulic manifold

A hydraulic integration and design method technology, applied in design optimization/simulation, computer-aided design, calculation, etc., can solve problems such as low degree of automation, partial loss along the process, and low efficiency, so as to improve design efficiency and energy Efficiency and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

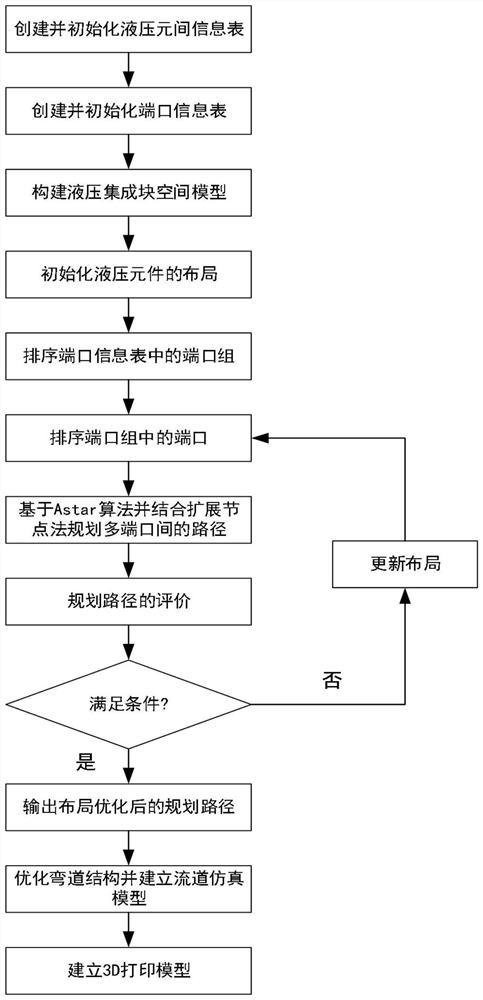

[0048] In this embodiment, as figure 1 As shown in the figure, a flow channel design method for an energy-efficient hydraulic manifold reduces the loss along the flow path and the local loss through layout optimization, inter-port path planning and local flow channel structure optimization, and improves the performance of the hydraulic manifold. energy efficiency, and the design results can be fabricated using 3D printing. Specifically, follow the steps below:

[0049] Step 1. Establish the mathematical model of the hydraulic manifold:

[0050] Step 1.1. Determine the hydraulic component model on the hydraulic manifold according to the hydraulic schematic diagram, and create and initialize the hydraulic component information table HC={hc 1 ,hc 2 ,...,hc i ,...,hc I }, where hc i is the information set of the ith hydraulic element, I is the total number of hydraulic elements; and there are:

[0051]

[0052] Among them, because of the different geometric shapes of hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com