Flexible feed mixing device for aquatic animal breeding

A technology for aquatic animals and feed, applied in the direction of feed, application, mixer, etc., can solve problems such as screen blockage, increased cost, and reduced processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

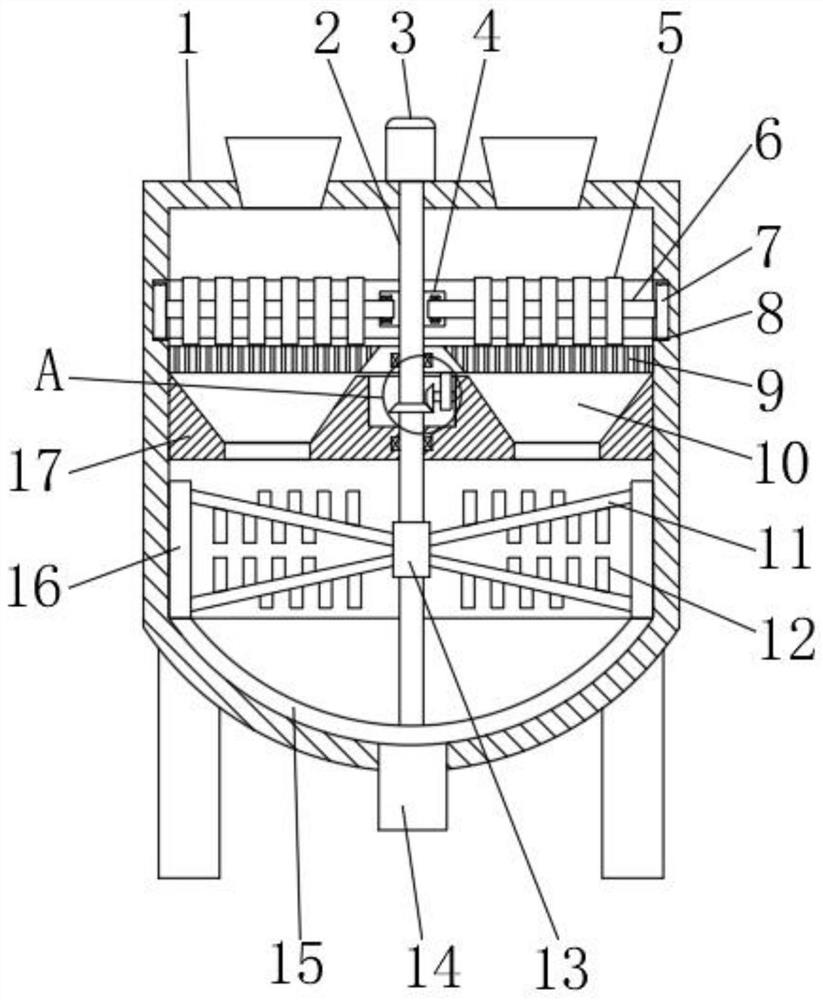

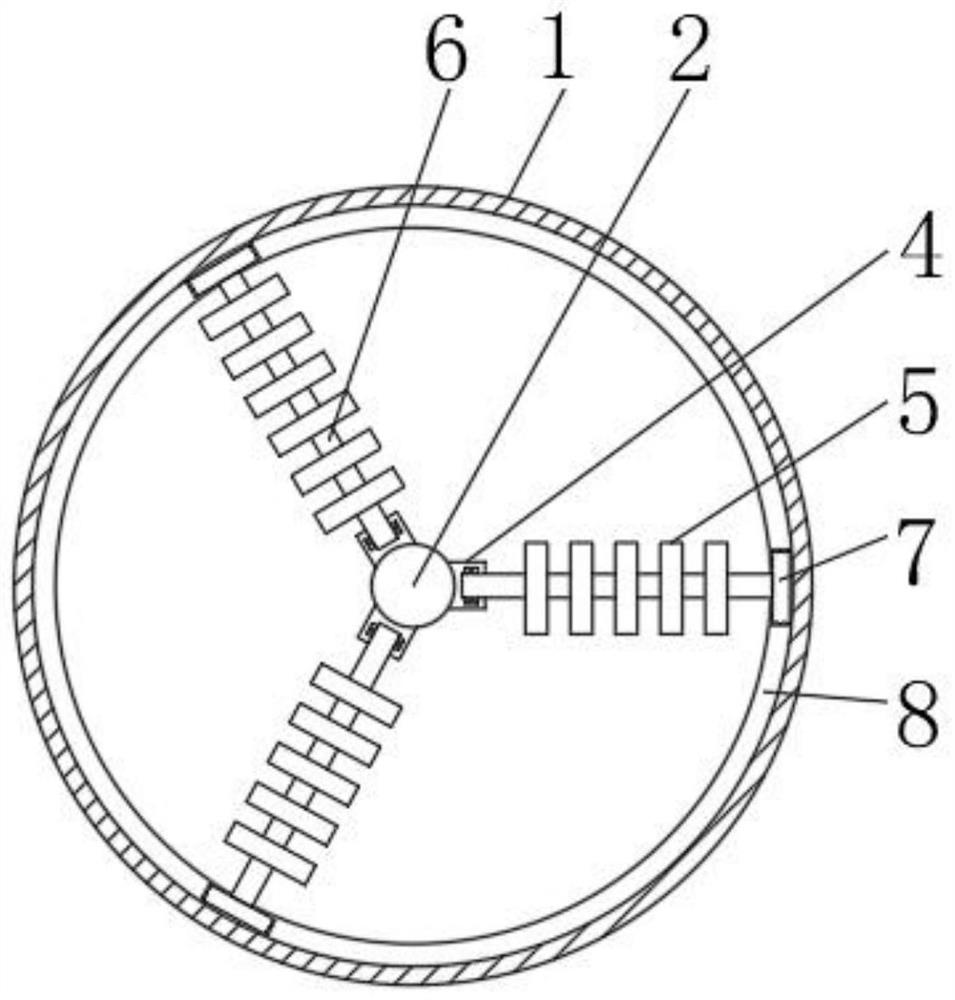

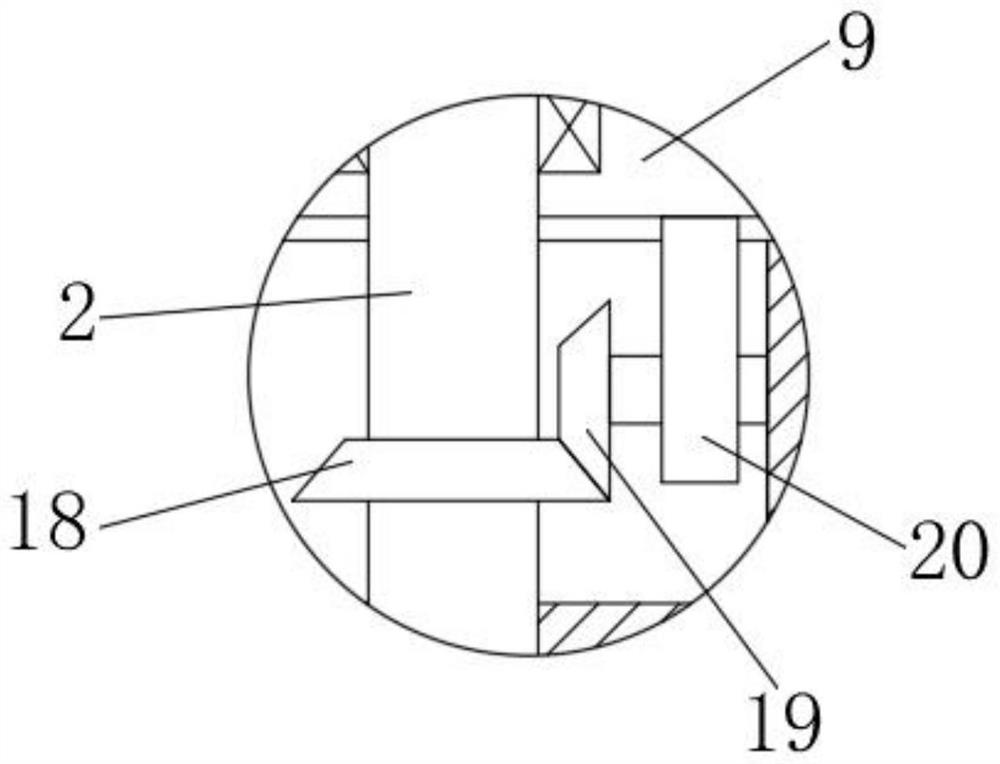

[0024] Embodiment one: refer to Figure 1~4 , in an embodiment of the present invention, a feed flexible mixing device for aquatic animal breeding, comprising a mixing box 1, a motor 3 is placed on the upper end of the mixing box 1, and a main shaft 2 is connected to the output end of the motor 3, which runs through the mixing box The upper end of the main shaft 2 inside 1 is fixed with a fixed block 4, and the internal bearing of the fixed block 4 is connected with a transmission shaft 6, and a plurality of rolling rollers 5 are evenly distributed on the transmission shaft 6, and the transmission shaft 6 is far away from the fixed block 4. One end is provided with a gear 7, and the gear 7 is meshed with a gear ring 8 set on the inner wall of the mixing box 1, so that the transmission shaft 6 drives the rolling roller 5 to revolve around and rotate at the same time, and the large grain feed material is rolled and refined to make it To meet the digestion granularity required by...

Embodiment 2

[0031] Embodiment 2: This invention also provides another embodiment, which is improved on the basis of the above embodiment, the outer wall of the scraper 15 and the side scraper 16 is closely connected with the inner wall of the mixing box 1 Fitting together effectively prevents the feed from accumulating in the mixing box 1 and causing mildew and deterioration.

[0032] To sum up, when this invention works, at first turn on motor 3, equipment operation, multiple raw materials are dropped into mixing box 1 through a plurality of feeding ports, at first sieve screen 9 screens out the feed raw material with bigger particle, through fixed block 4, and the meshing constraints of the gear 7 and the gear ring 8, the transmission shaft 6 drives the rolling roller 5 to revolve and rotate simultaneously, and the feed raw materials are rolled and refined to meet the digestion needs of aquatic animals. The net 9 is blocked, and the driving bevel gear 18 on the main shaft 2 meshes with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com