Surface treatment system and surface treatment method for covering plates

A technology for surface treatment and cladding, applied in the direction of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low cleaning ability, single cleaning ability, and inability to effectively meet the needs of aluminum-based cladding panels Need and other questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

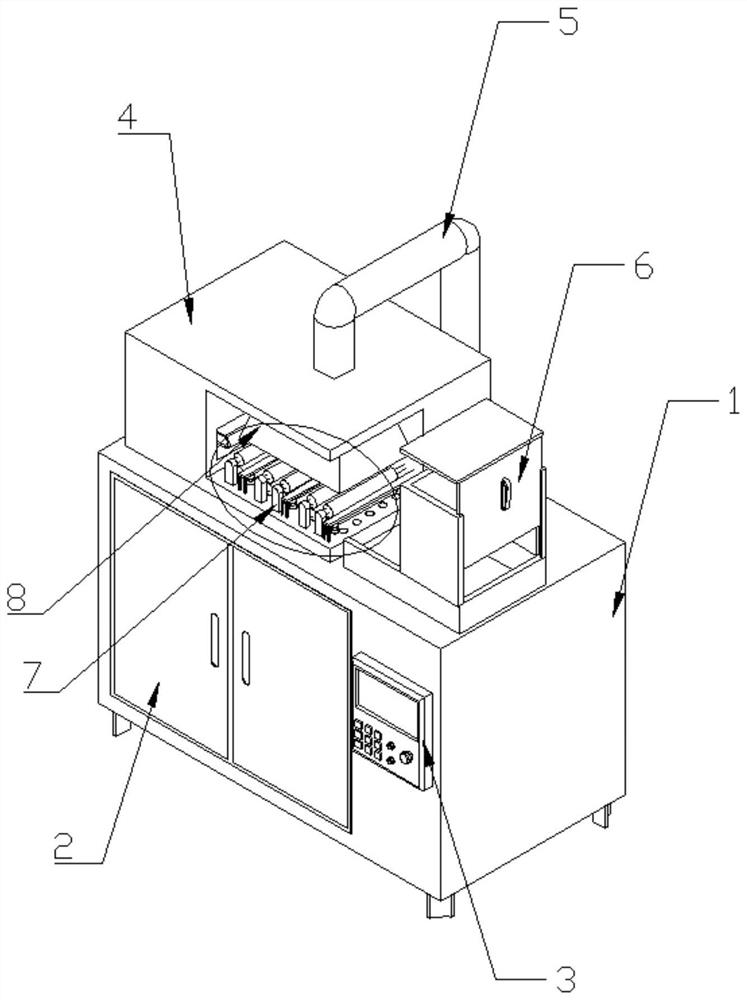

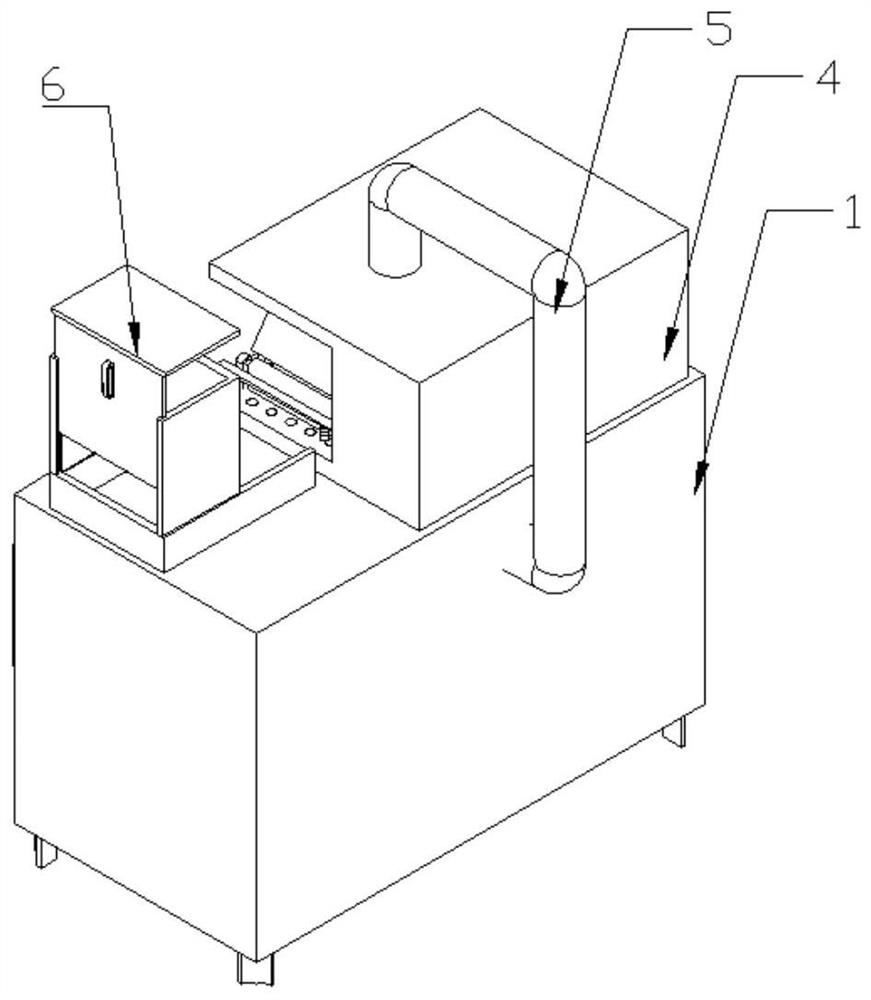

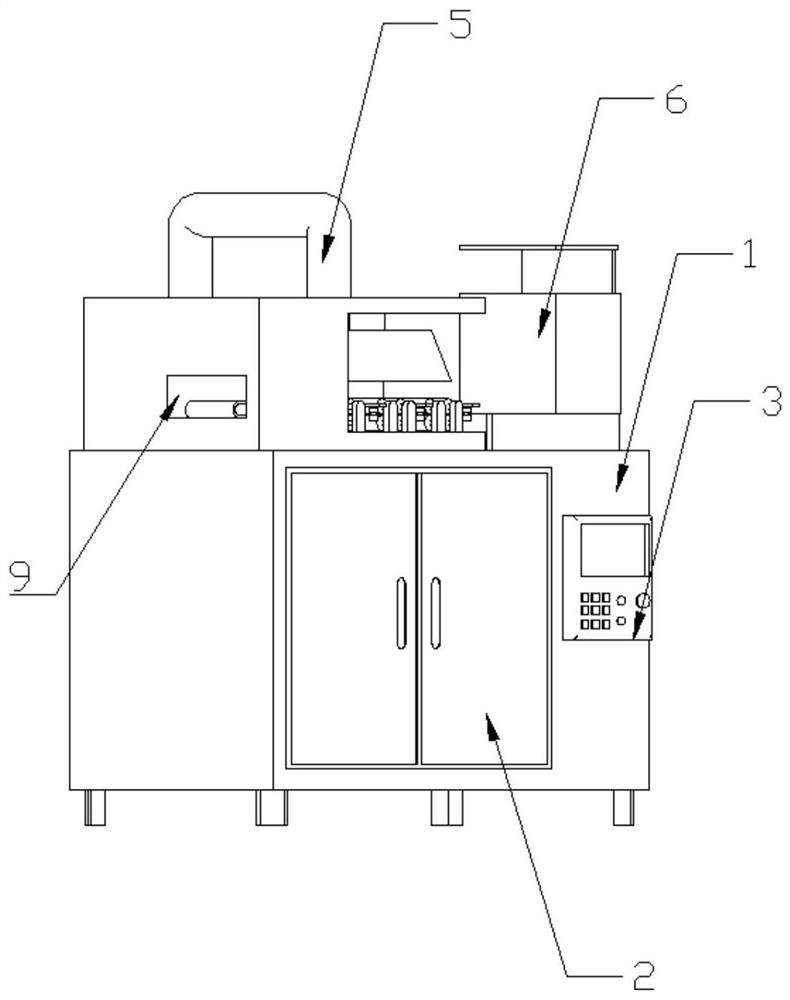

[0050] Please refer to Figure 1 to Figure 9 As shown, it shows the specific structure of the preferred embodiment of the present invention, a surface treatment system for cladding panels, including the following structure.

[0051] Cabinet body 1, box door 2, industrial computer 3, protective cover 4, vacuum pipe 5, cladding panel automatic transmission mechanism 6, cladding panel transmission and cleaning assembly 7, dust collection cover 8, conveyor belt 9 and dust suction hole 10, One side of the cabinet body 1 is provided with a side-opening box door 2; the industrial computer 3 is arranged on one side of the box door 2, and is fixedly connected with the cabinet body 1; the protective cover 4 is fixedly installed on the cabinet body 1, the top of the protective cover 4 is connected with a suction pipe 5 for dust collection;

[0052] The cladding panel automatic transmission mechanism 6 is arranged on one side of the protective cover 4, and is fixedly installed on the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com