Laser surface treatment equipment

A laser surface treatment and laser technology, which is applied in laser technology and its application field, can solve the problems of high cost, large land occupation, and low processing efficiency, and achieve the effect of reducing floor space, reducing cost, and improving surface treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

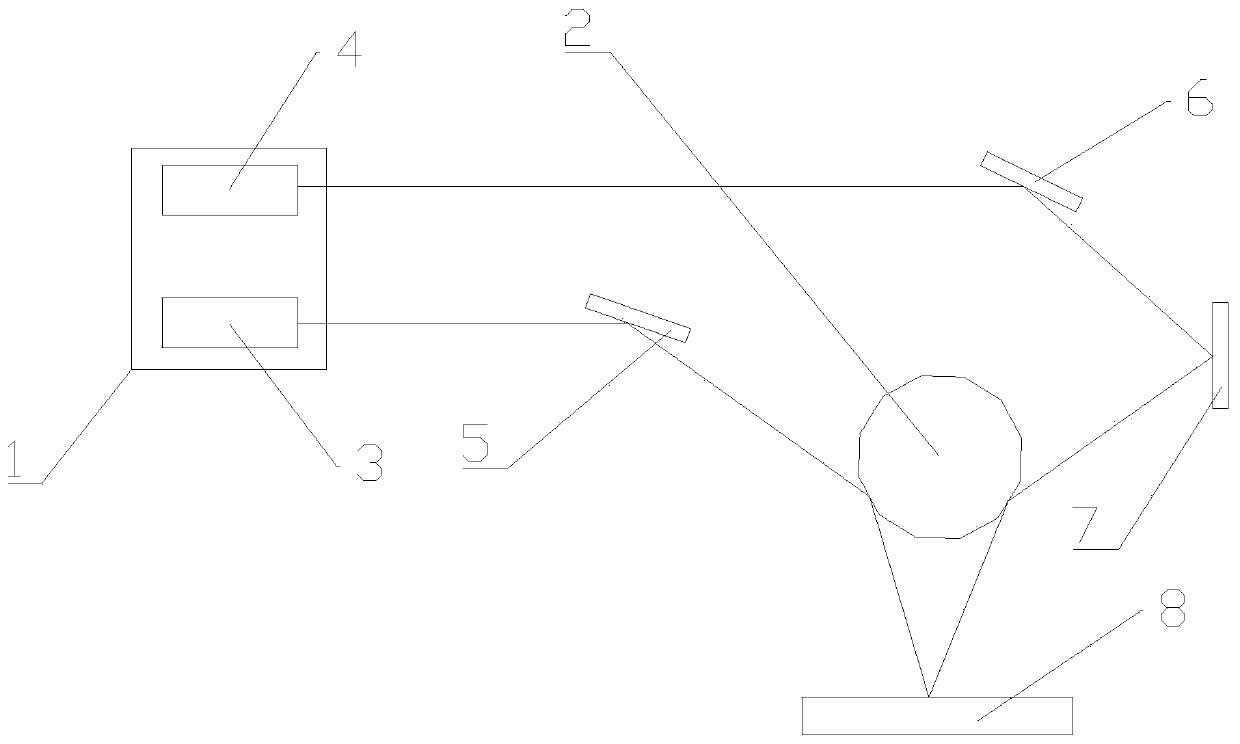

[0043] Please refer to figure 1 , a laser surface treatment equipment, including a laser component 1, a reflective component and a polygonal rotating mirror 2;

[0044] The laser assembly 1 includes a first laser emission source 3 and a second laser emission source 4 arranged sequentially from bottom to top. The power of the first laser emission source 3 and the second laser emission source 4 emitting laser light is different, and the higher power Laser irradiating the surface of the part can effectively remove oxides and pollutants on the metal surface, while the lower power laser irradiates the surface of the part for pretreatment, which can prepare for the subsequent anti-rust process. When the mirror 2 rotates, it will continuously improve the position of the laser irradiation on the surface of the part 8 to be processed, thereby jointly ensuring the improvement of surface treatment efficiency;

[0045] The reflective assembly reflects the laser light emitted by the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com