A preparation process of anti-friction and wear-resistant gear parts

A technology for preparation process and parts, which is applied in the field of preparation process of anti-friction and wear-resistant gear parts, can solve the problems of mechanically matching PVD coating with high hardness and low hardness, unsatisfactory performance of coating, and inability to obtain PVD coating, etc., to achieve improvement Effects of surface treatment efficiency, good support matrix, and mitigation of differences in physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

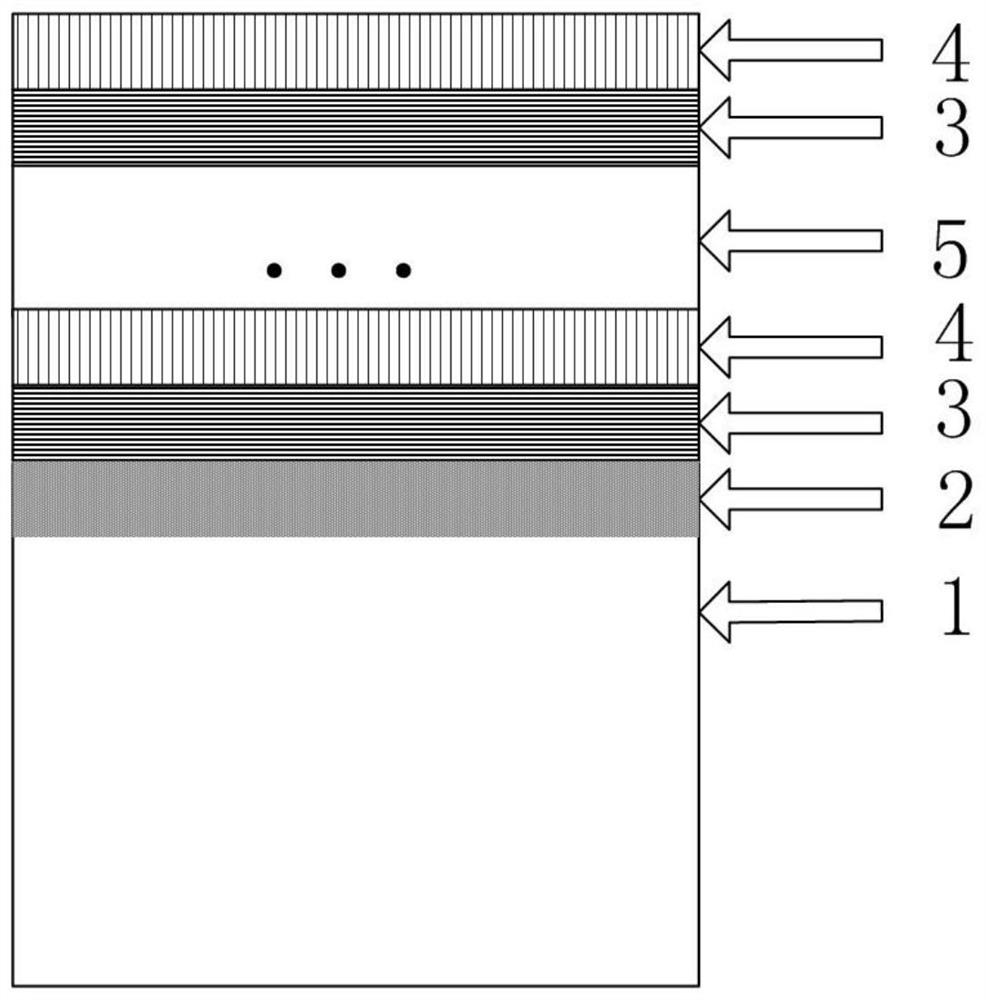

Image

Examples

Embodiment 1

[0029] In the preparation method of wear-resistant gear parts of the present invention, the base material of the gear parts is 22CrNi2MoNbH; The VCrWSiC / Cr multi-layer composite coating on the surface was deposited by the controlled sputtering composite method. During the deposition, 2 C ion plating targets, 1 V magnetron sputtering target, 1 Cr magnetron sputtering target, and 1 W magnetron sputtering target were used. Sputtering target and 1 Si magnetron sputtering target;

[0030] Specifically include the following steps:

[0031](1) Parts processing: parts base blank → quenching (835 ~ 885 ° C, water cooling) → high temperature tempering (525 ~ 565 ° C, water cooling) → roughing → semi-finishing → stress relief tempering (505 ~ 565 ° C, air cooling) )→finishing (surface roughness Ra1.6μm, processing size: lower tolerance limit);

[0032] (2) Parts surface pretreatment: use metal cleaning agent to remove oil stains on the surface of the workpiece, rinse and dry;

[0033]...

Embodiment 2

[0044] In the preparation method of wear-resistant gear parts according to the present invention, the base material of the gear parts is 20MnB, the base of the gear parts is subjected to quenching, high temperature tempering, rough finishing and then carburizing by ion plating, and then ion plating and magnetic The VCrWSiC / Cr multi-layer composite coating on the surface was deposited by the controlled sputtering composite method. During the deposition, 2 C ion plating targets, 1 V magnetron sputtering target, 1 Cr magnetron sputtering target, and 1 W magnetron sputtering target were used. Sputtering target and 1 Si magnetron sputtering target;

[0045] Specifically include the following steps:

[0046] (1) Parts processing: parts base blank → quenching (900 ~ 945 ° C, oil quenching) → high temperature tempering (525 ~ 600 ° C, air cooling) → rough machining → semi-finishing → stress relief tempering (555 ~ 595 ° C, Oil cooling)→finishing (surface roughness Ra1.6μm, processing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com