Surface treatment process of titanium or titanium alloy dental implant

A technology for tooth implantation and surface treatment, applied in the improvement of process efficiency, dentistry, dental implants, etc., can solve the problems of low bonding strength of bone tissue, long healing time, uneven porous structure, etc. Water-based, the effect of improving microscopic morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

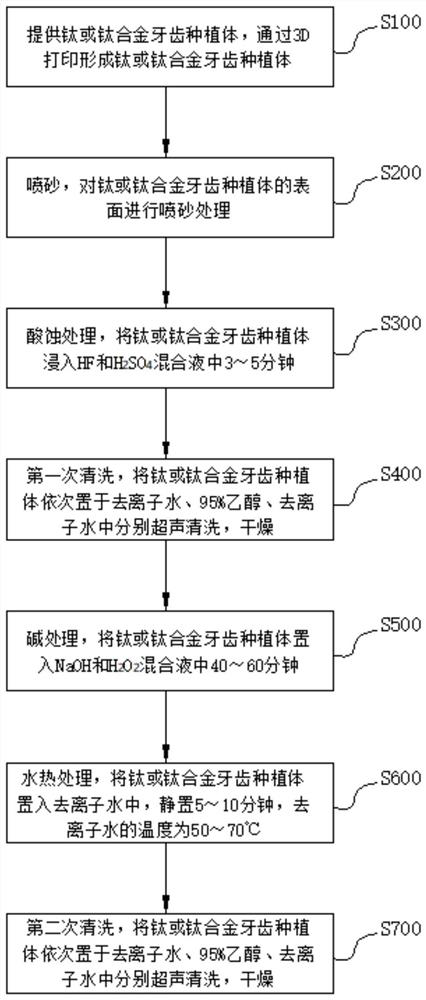

[0026] A kind of surface treatment process of titanium or titanium alloy dental implant, refer to figure 1 shown, including the following steps:

[0027] S100: Provide titanium or titanium alloy dental implants, form titanium or titanium alloy dental implants by 3D printing: use metal titanium or titanium alloy powder as raw material, form the implant part with 2 to 4 implant teeth by 3D printing Titanium or titanium alloy dental implants, and a rough surface can be formed on titanium or titanium alloy dental implants. The advantage of using 3D printing is that it can realize customized implant services according to the actual needs of patients;

[0028] S200: Sandblasting, sandblasting the surface of titanium or titanium alloy dental implants, using 60 mesh titanium dioxide to perform sandblasting treatment on the surface of titanium or titanium alloy dental implants, the spraying distance is 80mm, the spraying time is 10s, sandblasting During the process, the axial inclinat...

Embodiment 2

[0035] A kind of surface treatment process of titanium or titanium alloy dental implant, refer to figure 1 shown, including the following steps:

[0036] S100: Provide titanium or titanium alloy dental implants, form titanium or titanium alloy dental implants by 3D printing: use metal titanium or titanium alloy powder as raw material, form the implant part with 2 to 4 implant teeth by 3D printing Titanium or titanium alloy dental implants, and a rough surface can be formed on titanium or titanium alloy dental implants. The advantage of using 3D printing is that it can realize customized implant services according to the actual needs of patients;

[0037] S200: Sandblasting, sandblasting the surface of titanium or titanium alloy dental implants, using 70-mesh titanium dioxide to perform sandblasting treatment on the surface of titanium or titanium alloy dental implants, the spraying distance is 80mm, the spraying time is 10s, sandblasting During the process, the axial inclinat...

Embodiment 3

[0044] A kind of surface treatment process of titanium or titanium alloy dental implant, refer to figure 1 shown, including the following steps:

[0045] S100: Provide titanium or titanium alloy dental implants, form titanium or titanium alloy dental implants by 3D printing: use metal titanium or titanium alloy powder as raw material, form the implant part with 2 to 4 implant teeth by 3D printing Titanium or titanium alloy dental implants, and a rough surface can be formed on titanium or titanium alloy dental implants. The advantage of using 3D printing is that it can realize customized implant services according to the actual needs of patients;

[0046] S200: Sandblasting, sandblasting the surface of titanium or titanium alloy dental implants, using 80 mesh titanium dioxide to perform sandblasting treatment on the surface of titanium or titanium alloy dental implants, the spraying distance is 80mm, the spraying time is 10s, sandblasting During the process, the axial inclinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com