Production method of high-barrier nylon PE co-extruded film

A production method and technology of co-extrusion film, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems that consumers cannot directly display the appearance of food, and the barrier performance cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

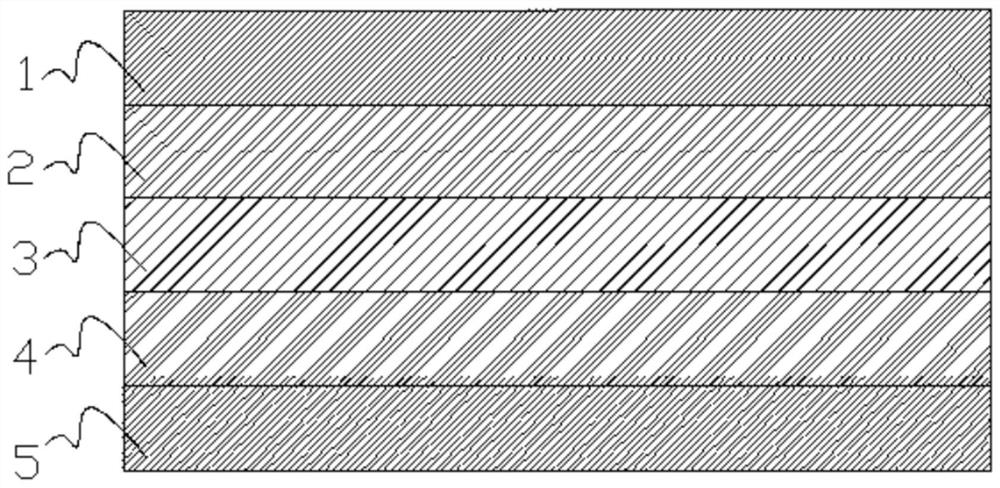

[0031] as attached figure 1As shown, a production method of high-barrier nylon PE co-extrusion film, including inner film layer and outer film layer: inner film layer includes continuous bonded surface layer PE layer 1, PA layer 2, modified PE layer 3, middle PE layer The layer 4 and the surface layer PA layer 5 are composed of a symmetrical nylon film bonded sequentially and an asymmetric nylon film bonded sequentially; the outer film layer includes a printing layer, a barrier layer and a heat-sealing layer, and is distributed sequentially from the inside to the outside. The specific production method Proceed as follows:

[0032] Step 1: The symmetrical nylon membrane bonded in sequence is constructed by glue layer, BOPA layer, and symmetrical nylon membrane, and the symmetrical nylon membrane is co-extruded with PE layer, modified TO layer, PA layer 2, and modified PE3 layer arranged in sequence made;

[0033] Step 2: The asymmetric nylon membrane bonded in sequence is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transverse stretch temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com