A high current channel selector pdu system

A channel selection, high-current technology, applied in current collectors, circuits, charging stations, etc., can solve the problems of complex lines, poor flexibility, and high calorific value, and achieve flexible distribution, strong applicability, and reduced calorific value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

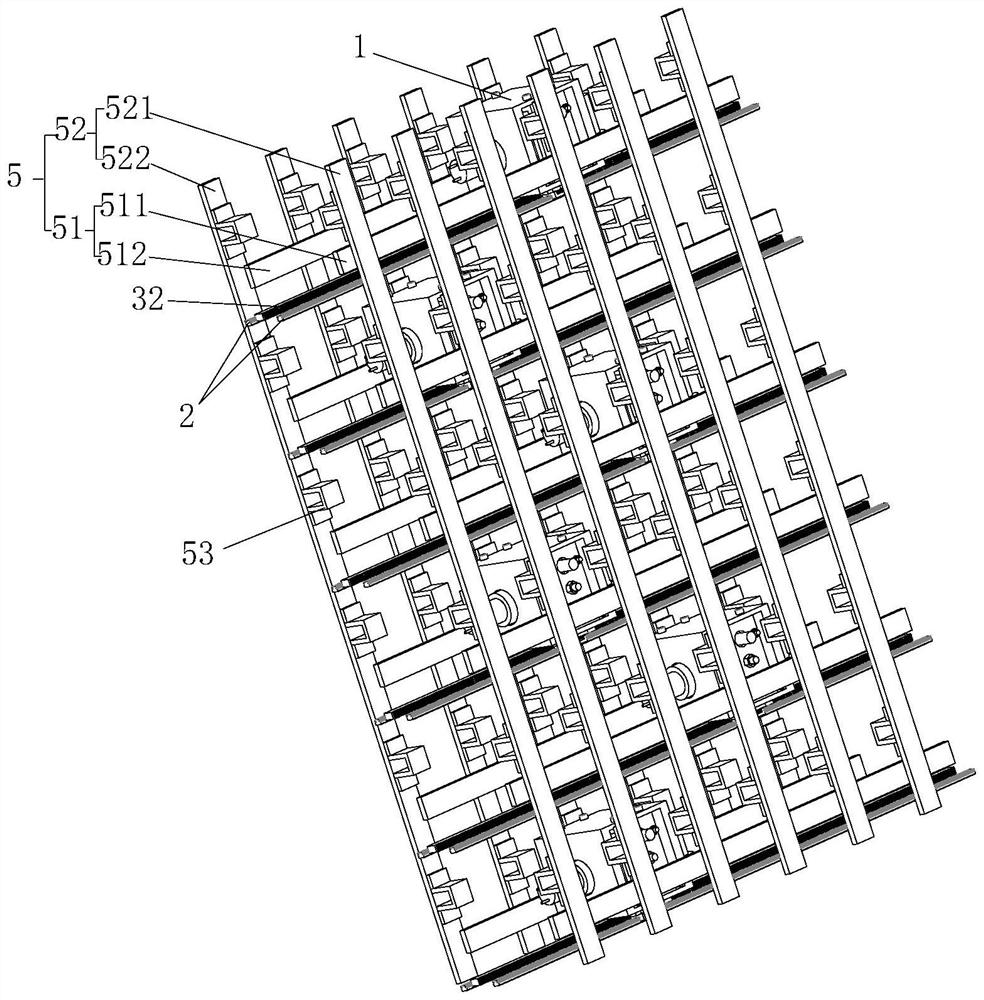

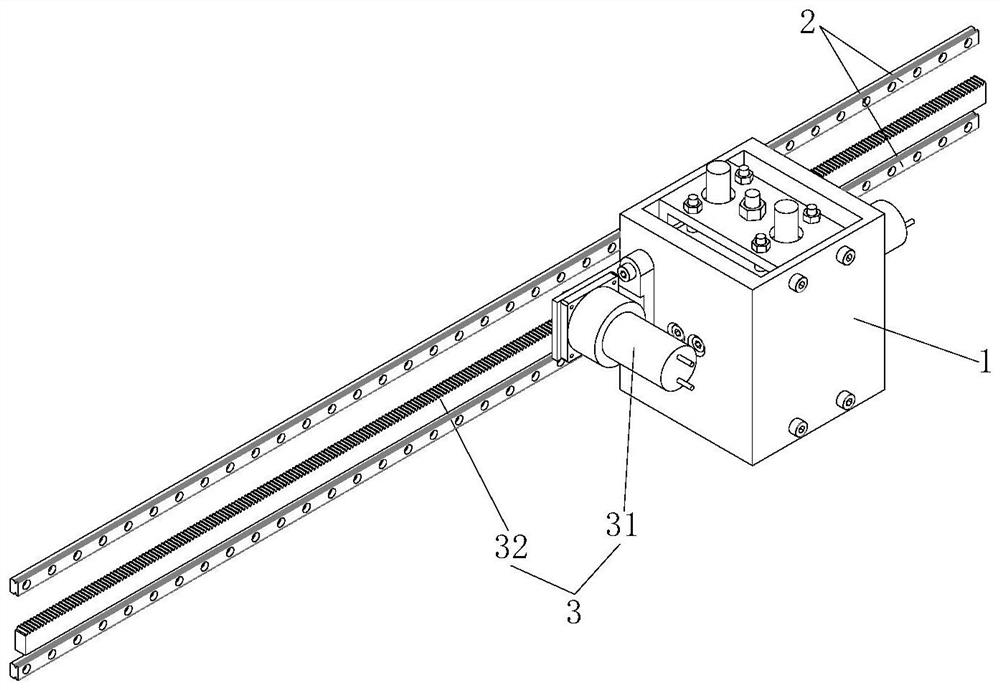

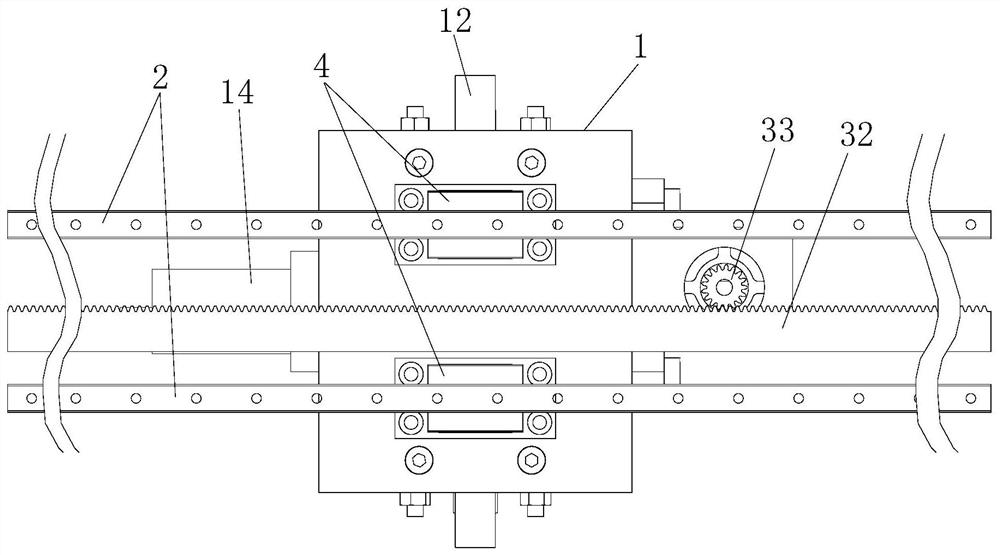

[0038] like Figure 1-6 As shown, this embodiment provides a high-current channel selection PDU system, including a PDU robot module 1 and an external channel 5. The external channels 5 are arranged in an array on the outer circumference of the PDU robot module 1, and the PDU robot module 1 moves to the workstation. , the electrode unit 12 in the PDU robot module 1 extends out and contacts with the external channel 5 to form an electrical connection.

[0039] The PDU robot module 1 includes a moving carrier 11, an electrode unit 12 and a driving member 14. The electrode unit 12 includes an input electrode 121 and an output electrode 122. The input electrode 121 and the output electrode 122 are electrically connected, and the input electrode 121 and the output electrode 122 are driven Under the driving action of the driving element 14, the element 14 extends from the moving carrier 11 to connect the external circuit; when the input electrode 121 and the output electrode 122 ret...

Embodiment 2

[0051] like Figure 7 As shown, this embodiment is basically the same as the first embodiment, and the only difference lies in the structure of the transmission assembly 15 . In this embodiment, the transmission assembly 15 includes a lead screw 151 and a nut 152. There is one lead screw 151 and two nuts 152. Both ends of the lead screw 151 are rotatably mounted on the side plate 112, and the two nuts 152 are symmetrical The two nuts 152 are arranged on the screw rod 151, and the two ends of the screw rod 151 are anti-jammed, so that the two nuts 152 can drive the two brackets 13 to move toward each other or backwards synchronously.

[0052] Further, a first helical gear 153 is connected to the driving end of the driving member 14 , a second helical gear 154 is provided on the screw rod 151 , and the first helical gear 153 and the second helical gear 154 are engaged.

Embodiment 3

[0054] like Figure 8 As shown, this embodiment is basically the same as the first embodiment, the only difference is that, in this embodiment, the transmission assembly 15 can be omitted, and the driving member 14 can be configured as a telescopic driving device. The driving part 14 includes a driving part 141 and a telescopic part 142. The driving part 141 and the telescopic part 142 are fixedly connected to the two brackets 13 respectively. The driving member 14 can be selected from but not limited to air cylinders, hydraulic cylinders, electric cylinders, and frame-type electromagnets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com