Visual simulation system of gravel aggregate production system

A simulation system and production system technology, applied in the field of sand and gravel aggregate production, can solve the problems of large deviation between production process and actual results, deviation and error of design results, different equipment parameter settings, etc., so as to facilitate accurate calculation, avoid Computational error, the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

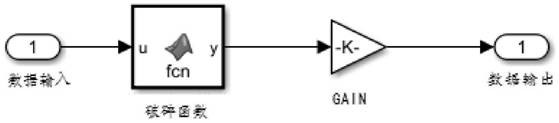

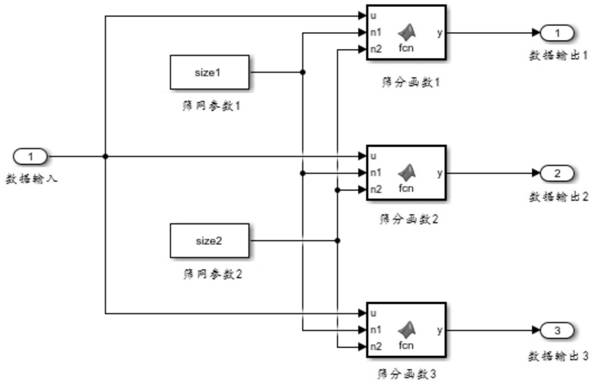

Method used

Image

Examples

Embodiment

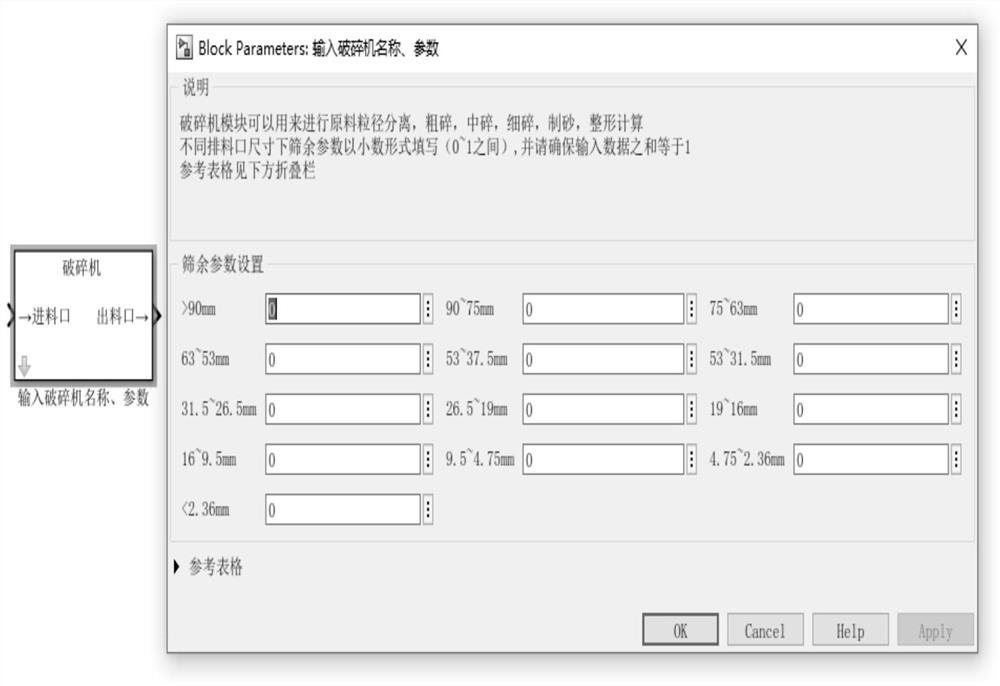

[0060] The present invention is described in detail in conjunction with the accompanying drawings and a project sand and gravel aggregate processing system process design and calculation case:

[0061] A sand and gravel aggregate production line in a project has a large amount of mud in the wool, and the average particle size of the wool is 130mm. The product is mainly asphalt concrete aggregate, and the product structure is mainly 16mm-9.5mm, 9.5mm-4.75mm, 4.75-2.36mm, >2.36mm four (according to "Construction Pebbles and Crushed Stones" (GB / T 14685-2011)), reserve 25mm to 16mm and 45mm to 25mm according to production needs (according to "Railway Gravel Ballast" (TB / T 2140-2008) division) two production line interfaces;

[0062] The sand and gravel aggregate processing process is as follows:

[0063] S1) Input the designed processing capacity through the unloading sub-module 501, and the processing capacity enters the virtual crushing sub-module 201 to simulate the particle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com