Efficient anti-vibration ion source filament assembly and manufacturing method thereof

A manufacturing method and ion source technology, which are applied in the manufacture of electrode assemblies, ion sources/guns, parts of particle separator tubes, etc., can solve the problems of insufficient high strength, poor anti-vibration performance, and insufficient anti-vibration performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

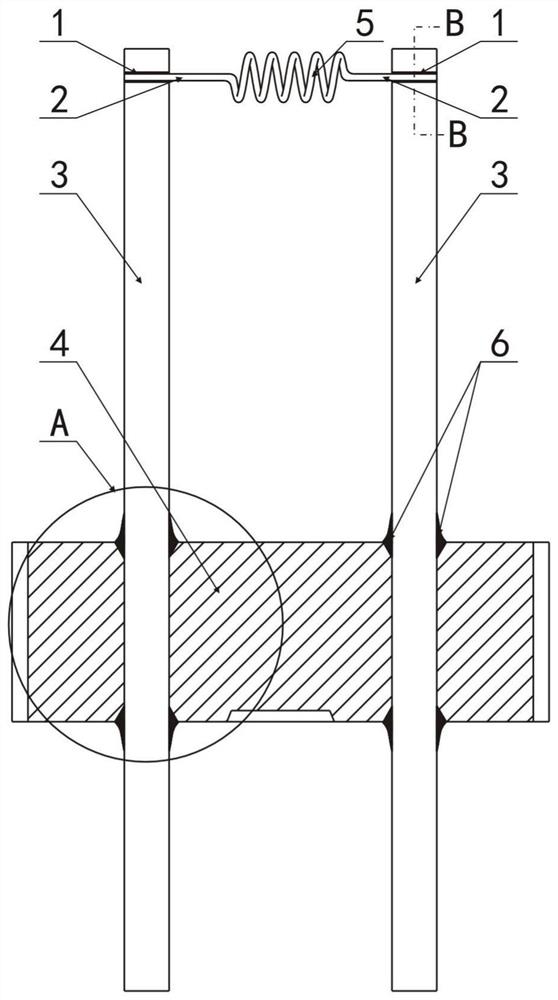

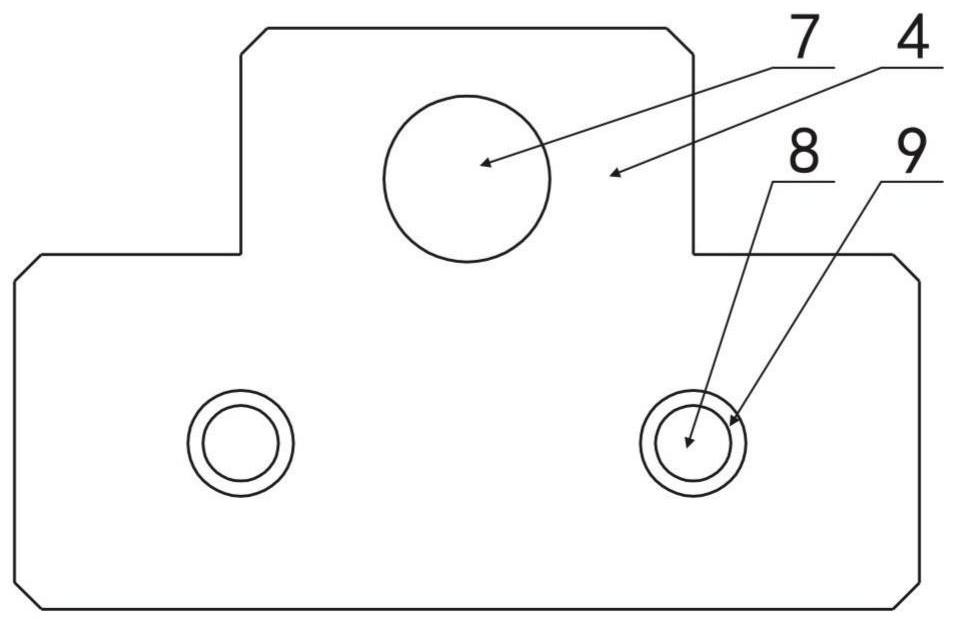

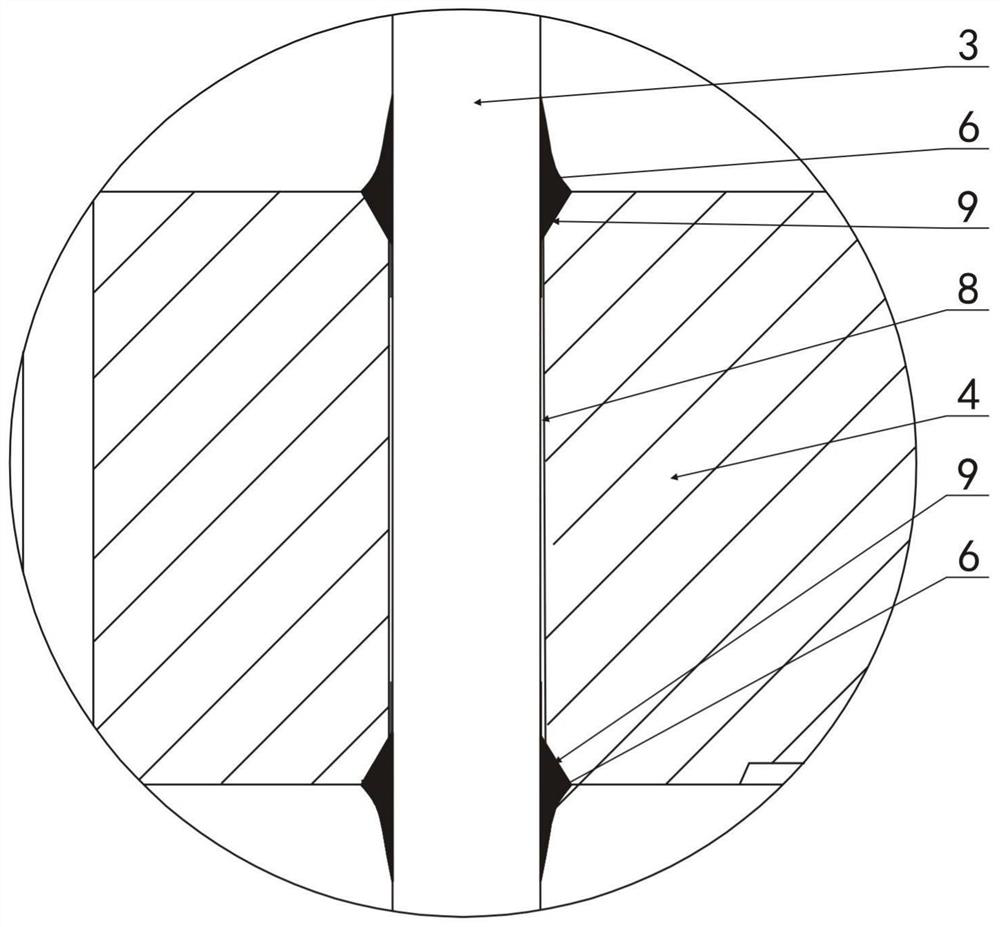

[0028] The present invention will be further described below in conjunction with accompanying drawing:

[0029] Such as Figure 1-Figure 4 As shown, the high-efficiency anti-vibration ion source filament assembly of the present invention includes a filament 5, an electrode 3 and a fixed base 4, the two ends of the filament 5 are connected to the first ends of the two electrodes 3, and the two electrodes 3 are close to the second The positions of the ends are respectively connected with the fixed base 4, the fixed base 4 is a ceramic base, the fixed base 4 is provided with two welding through holes 8, and the hole walls at both ends of the welding through hole 8 are provided with metallized metal metallization layer (not shown in the figure but easy to understand), the second ends of the two electrodes 3 respectively pass through the two soldering holes 8 and are soldered to the corresponding metallization layer.

[0030] Preferably, the electrode 3 is brazed with the correspo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com