All-working-condition self-adaptive pH adjusting method

An adjustment method and self-adaptive technology, which is applied in the field of pH adjustment, can solve problems such as not considering the influence of pH value, and achieve the effect of reducing limestone consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

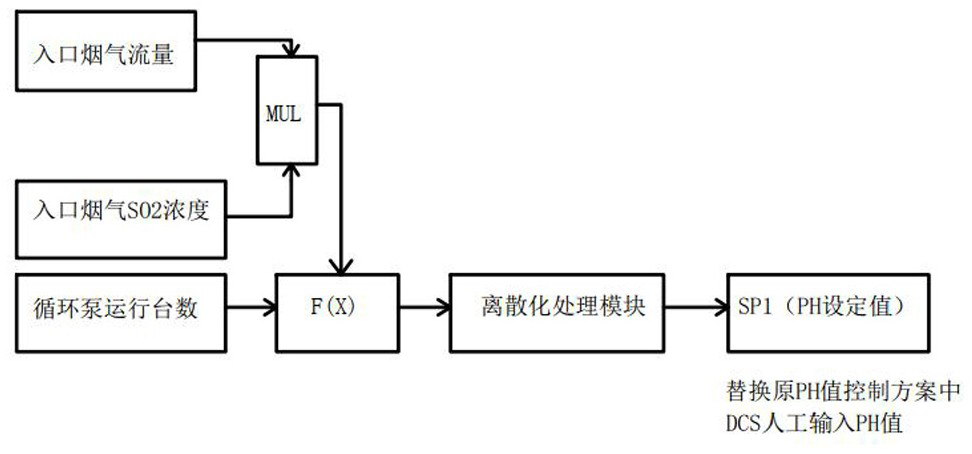

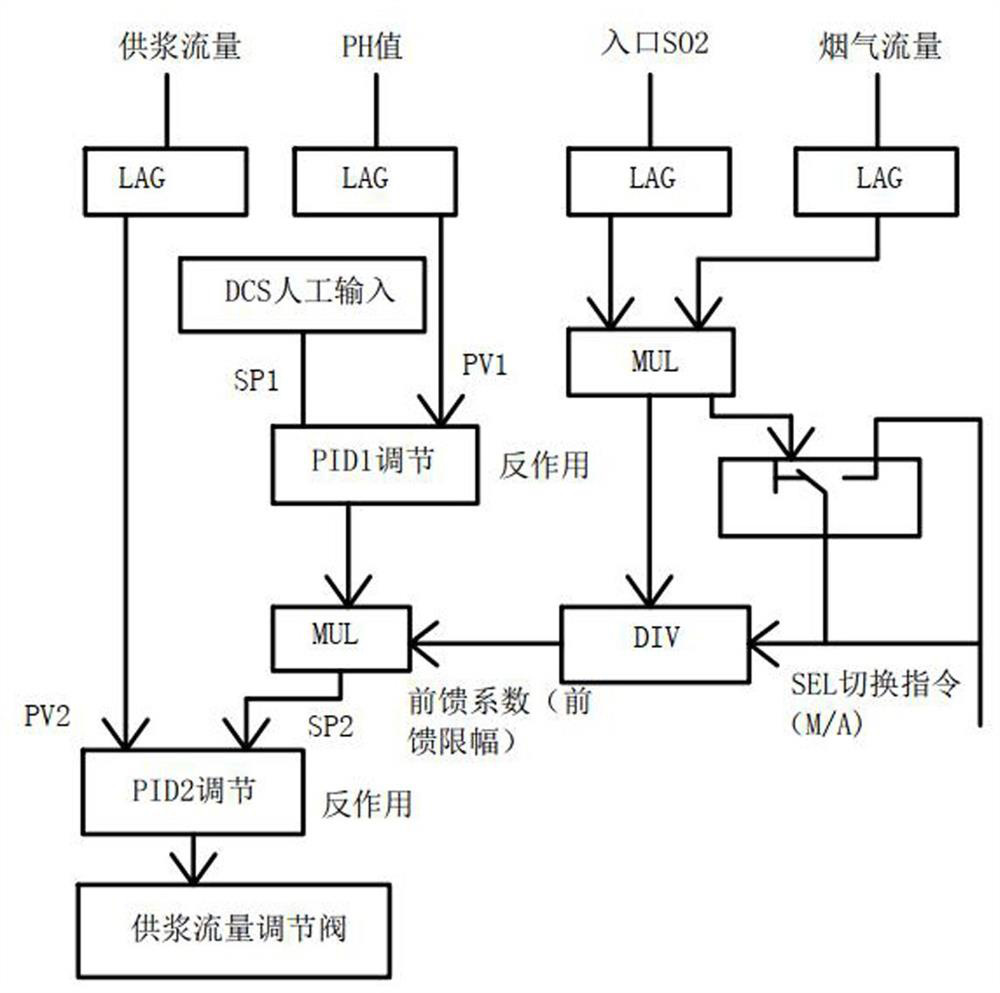

[0042]figure 2 A flow chart of the original pH automatic control scheme, where the original pH set value is manually input to the DCS screen,figure 1 The application flow chart of the fully working condition adaptive pH adjustment method according to an embodiment of the present invention is shown. In the pH control scheme, the determination of the pH setting value SP1 isfigure 1 The method automatically calculates the input, and no longer uses the form of manual input of DCS screen. The full-conditioning method of the present invention is adapted to the pH adjustment method including the following steps.

[0043]Step 1: Collection of data,

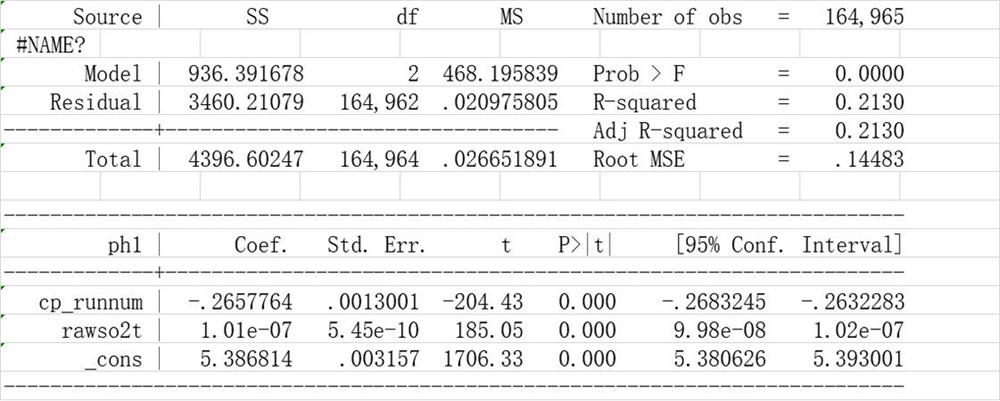

[0044]First choose the original flue gas flow, the original flue gas SO2Concentration (dry stated state), various circulatory pump operating status points, DCS historical data such as parameter points such as each cycle pump running current, pH, tube flow (screening out effective maximum flue gas SO2Load and minimum load: original flue gas flow, orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com