Rotational flow sand separating device and sand separating machine

A flow divider and cyclone technology, which is applied to cyclone devices, devices whose axial directions of cyclone can be reversed, etc., can solve problems such as inability to handle mud, achieve waste reuse, improve construction efficiency, and save resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

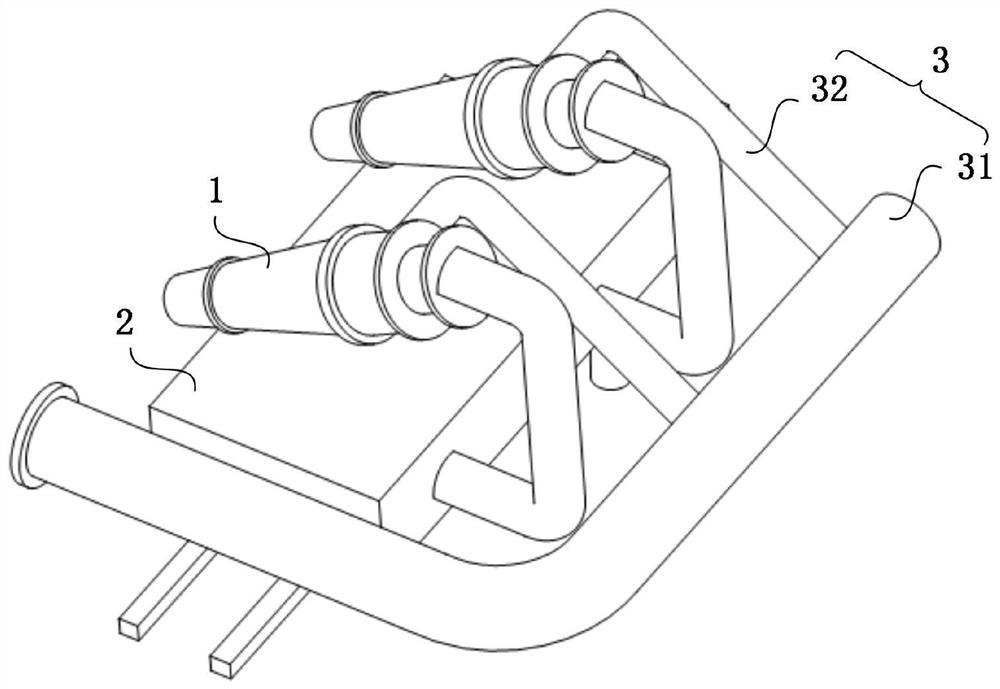

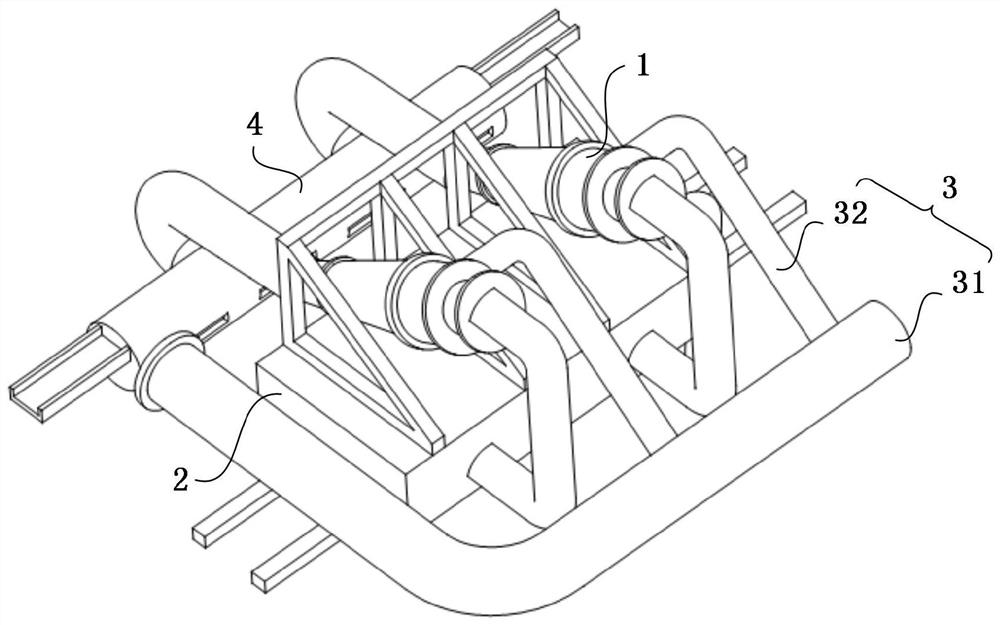

[0035]As an embodiment of the present invention, the input system 3 includes a pump body, a first input pipe 31 and at least one second input pipe 32. The swirler 1 is connected, and the second input pipe 32 corresponds to the swirler 1 one by one. In this way, the pump body can provide power for the entire input system 3, so that the mud can enter the cyclone 1 from the first input pipe 31 through at least one second input pipe 32, and the staff can also control the opening and closing of the pump body. Turn off and control the swirl sand separator, the control mode is simple, and it is convenient to control the swirl sand separator.

[0036] As another embodiment of the present invention, the input system 3 includes a first input pipe 31, at least one pump body and at least one second input pipe 32, the pump body is used to provide power, and the pump body and the second input pipe 32 are one by one Correspondingly, the first input pipe 31 communicates with the cyclone 1 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com