Antimony and/or bismuth nanosheet, antimonene and/or bismuthene as well as preparation methods and application thereof

A technology of nanosheets and bismuth nanosheets, applied in the field of antimony and/or bismuth nanosheets, antimonene and/or bismuthene, which can solve the problems of short preparation cycle and achieve the effects of low cost, easy preparation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

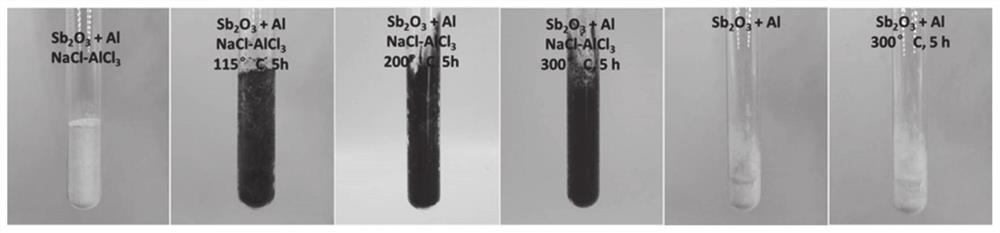

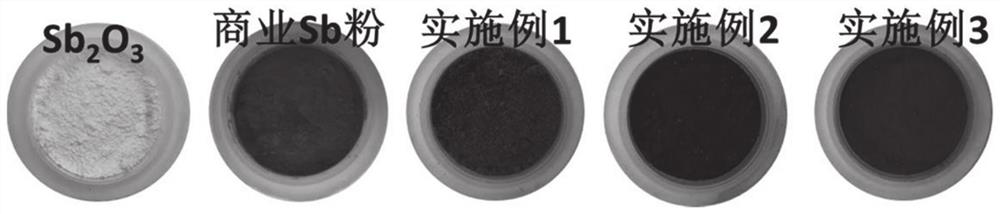

[0083] Example 1 Preparation of antimony nanosheets and extremely thin antimony nanosheets

[0084] Sodium chloride (NaCl), aluminum chloride (AlCl) 3 ), antimony oxide (Sb 2 o 3 ) and aluminum powder (Al) are placed in the test tube after being mixed evenly according to the amount shown in Table 1, and then the test tube containing the substance is reacted for 5 hours in the heater at the temperature shown in Table 1, and the test tube is taken out after the reaction is completed. After natural cooling, inject 300ml of deionized water into the reacted test tube, then add 30ml of concentrated hydrochloric acid for pickling, finally centrifuge, and use 150ml and 150ml of dilute hydrochloric acid with a volume ratio of deionized water:concentrated hydrochloric acid=1:10 to remove Wash with ionized water and 50ml ethanol. After drying, the product is antimony nanosheets.

[0085] The antimony nanosheets prepared above were mixed with 10g·L -1 The concentration is dispersed...

Embodiment 2-3

[0086] Example 2-3 Preparation of antimony nanosheets and extremely thin antimony nanosheets

[0087] The antimony nanosheet preparation method is as described in Example 1, except that the amount of each substance is changed according to Table 2.

[0088] The preparation of thin antimony nanosheets is as described in Example 1.

Embodiment 4-6

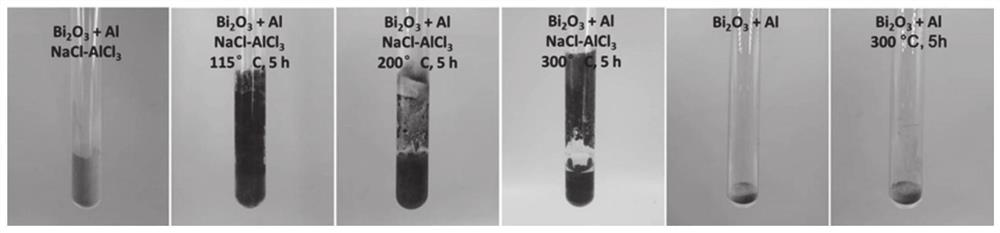

[0089] Example 4-6 Preparation of bismuth nanosheets and extremely thin antimony-bismuth nanosheets

[0090] The preparation method of bismuth nanosheets is as described in Example 1, and the difference is that antimony oxide is replaced by bismuth oxide (Bi 2 o 3 ), and adjust the amount of each substance as shown in Table 2.

[0091] The preparation of extremely thin bismuth nanosheets (bismuthene) is as described in Example 1.

[0092] Table 1 prepares the raw material and consumption of antimony nanosheet

[0093]

[0094] Table 2 prepares raw materials and consumption of bismuth nanosheets

[0095]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com