Shape trimming method and device for honeycomb sandwich floor part

A technology of honeycomb interlayer and parts, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve problems such as low efficiency and small out-of-tolerance size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

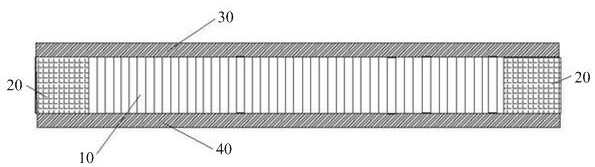

[0028] Composite material honeycomb sandwich floor parts are composed of upper and lower composite skins with a honeycomb core sandwiched in the middle. After the shape of the composite honeycomb sandwich panel is processed by numerical control, the honeycomb core around the panel is exposed. In order to reduce the corrosion of the honeycomb core by the environment, it is generally required to remove a certain depth of honeycomb core around the honeycomb panel, and then use adhesives for edge sealing ,Such as figure 1 As shown, there is a honeycomb core 10 in the middle, edge sealants 20 on both sides, an upper skin 30 on the upper surface, and a lower skin 40 on the lower surface. In order to meet the floor assembly requirements, the design has strict requirements on the shape tolerance of the floor parts, generally within the tolerance range of -0.5 ~ 0mm, and after using adhesive for edge sealing, the edge sealing glue around the board will be raised and uneven, The outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com