Combined cutting tool for automatic grinding device of spotwelding electrode

A spot welding electrode and dresser technology, which is applied in the direction of manufacturing tools, grinding workpiece supports, and other manufacturing equipment/tools, can solve the problem of cutting edge wear or chipping, great difference in working load or bending moment, and cutting edge Problems such as rapid wear or chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

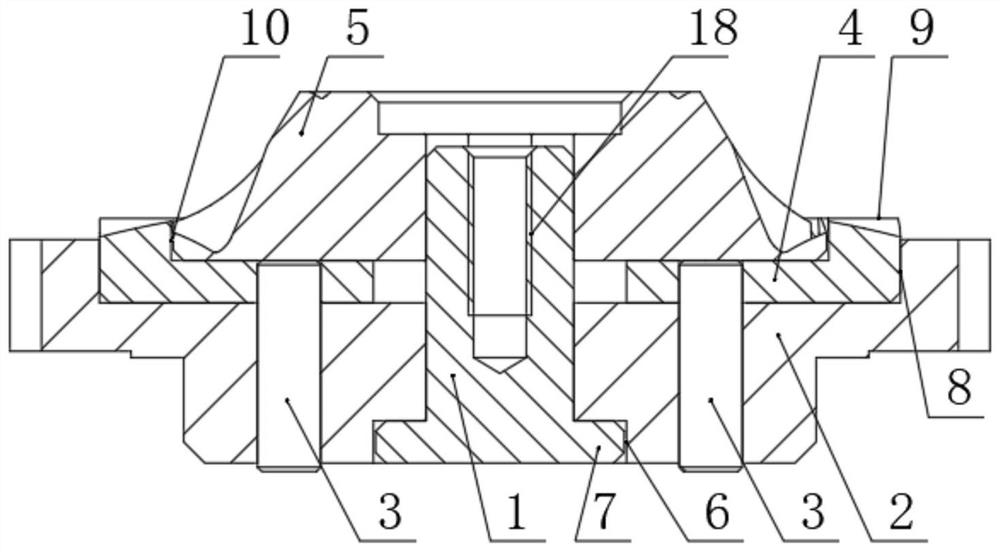

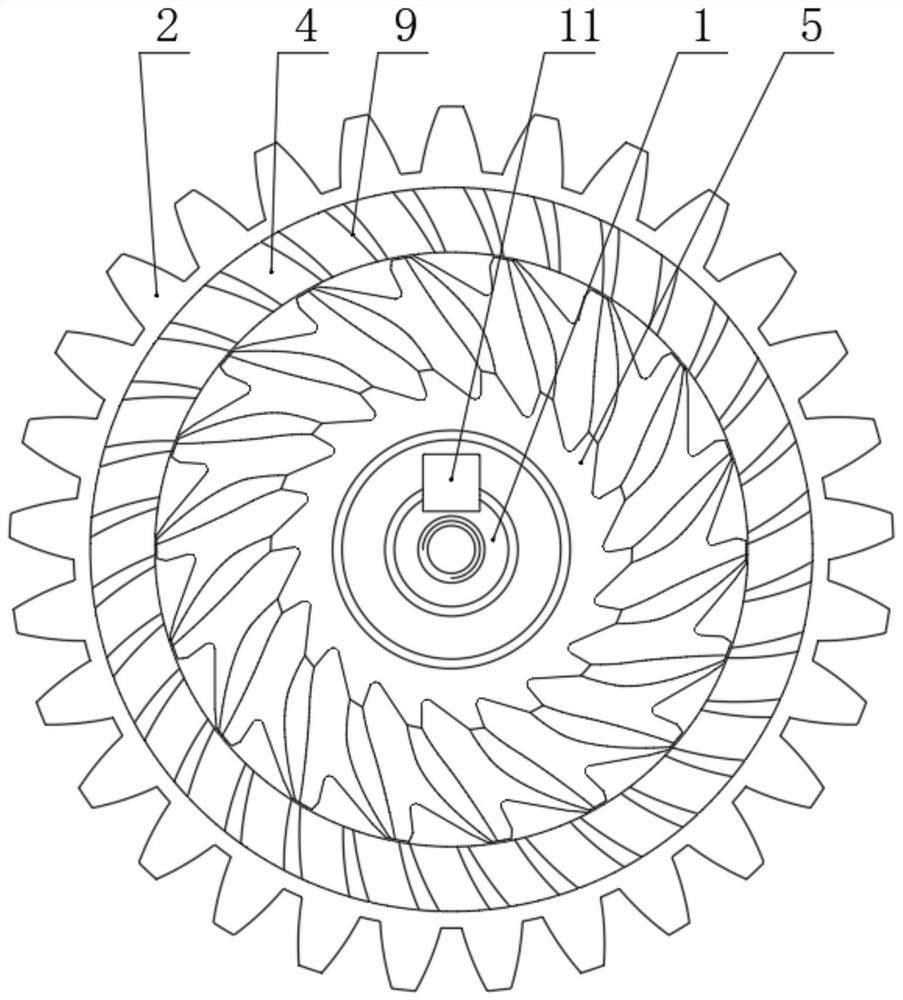

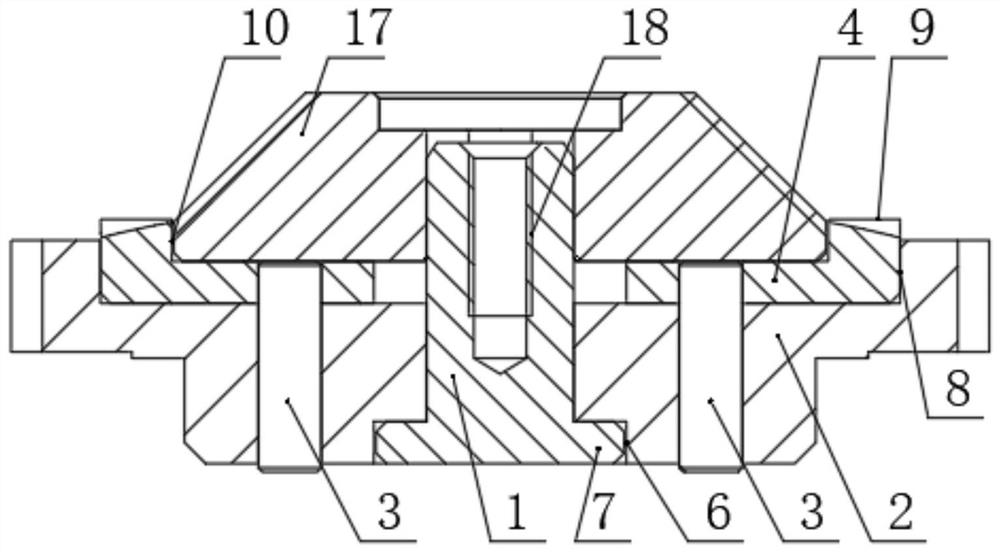

[0061] A combined cutting tool for a spot welding electrode automatic sharpener, including a cutter shaft 1, the shaft end of which is equipped with a spur gear 2; the innovation of the present invention is that: one end of the cutter shaft 1 has a flange 7, and the The inner surface of the flange 7 is used as the positioning base surface when the spur gear 2 is assembled with it; the other end of the cutter shaft 1 is provided with a threaded hole 18 in the center of the shaft, and the threaded hole 18 is used for the axial constraint of the cutter shaft 1 When the bolt assembly hole (.

[0062] Such as Picture 1-1 , Figure 1-2 , diagram 2-1 and Figure 2-2 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com