Connecting handle water jet cutting manufacturing method

A technology of waterjet cutting and manufacturing methods, which is applied in the direction of manufacturing tools, used abrasive processing devices, abrasives, etc., can solve the problems of time-consuming and labor-intensive connecting handle products, scrapping, etc., and achieve an increase in yield and good economic value , The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

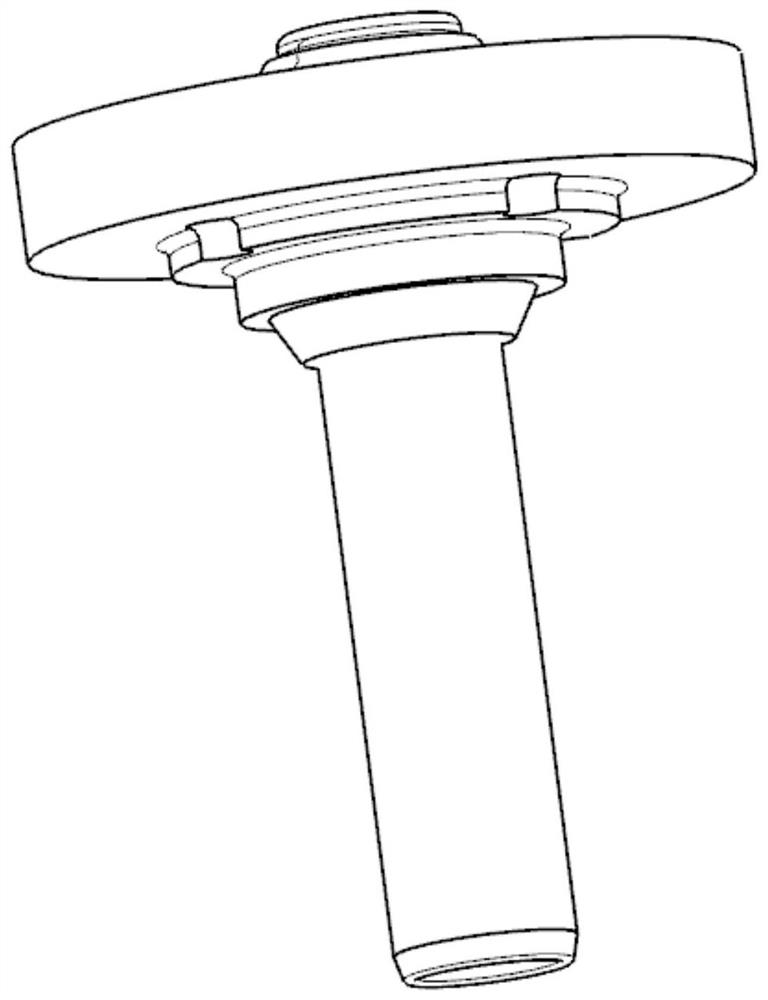

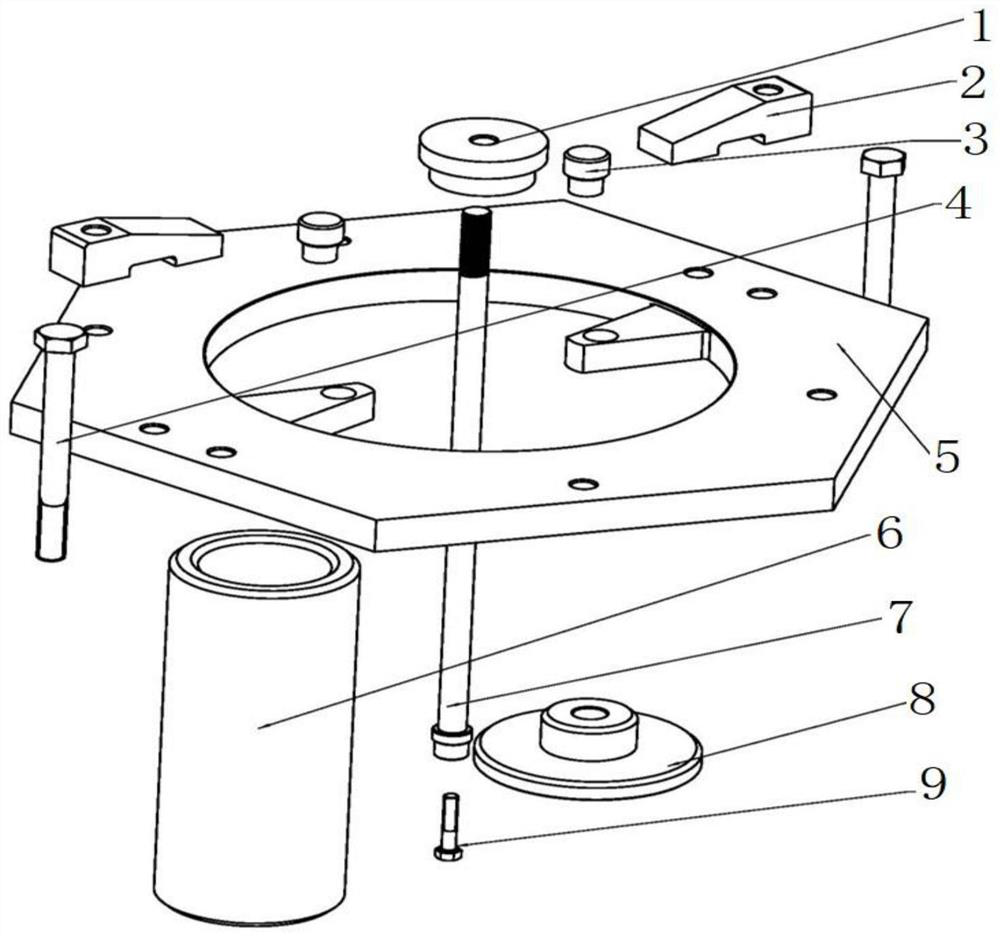

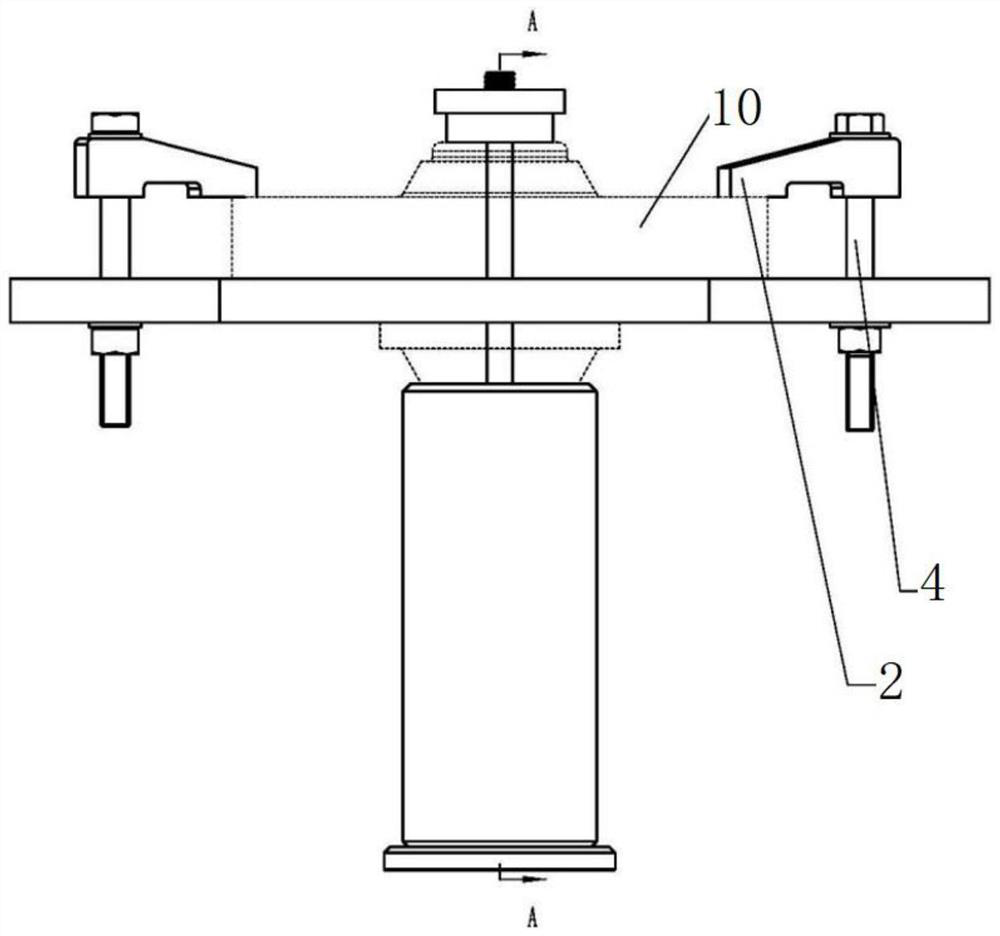

[0034] A connection handle water jet cutting manufacturing method, including water jet cutting pre-treatment, water jet cutting and water jet cutting post-processing; the water jet cutting process uses the connection handle water jet cutting fixture to clamp the workpiece to be cut, using garnet as The water jet cuts the abrasive and controls the cutting accuracy.

[0035] The above method for manufacturing the connecting handle by waterjet cutting specifically includes the following steps: Step 1. Re-inspection of raw material profiles: 100% inspection of the appearance quality and size of the raw material profiles; cutting small samples on the raw material profiles for re-examination of its chemical composition; Cut the standard tensile sample on the raw material profile, and carry out the tensile test, grain size determination and corrosion resistance test after the standard tensile sample is machined.

[0036] Step 2. Shape of the rough-turned connection handle: Use CNC pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com