Smokeless carbon cart

A carbon cart and car body technology, applied in the field of smokeless carbon carts, can solve problems such as dumping difficulties, and achieve the effects of low cost, simple structure, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

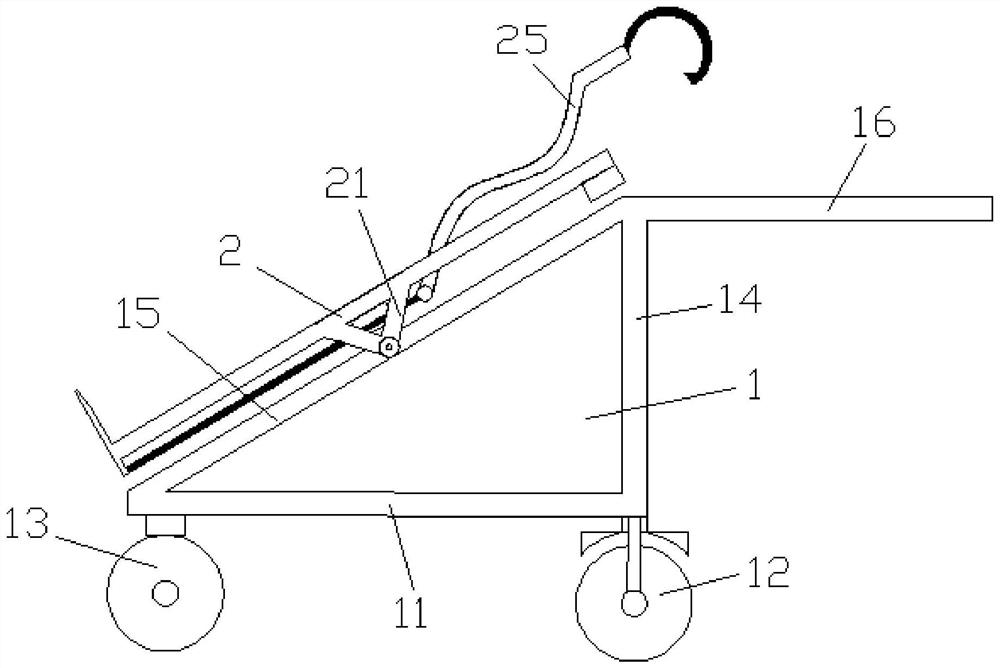

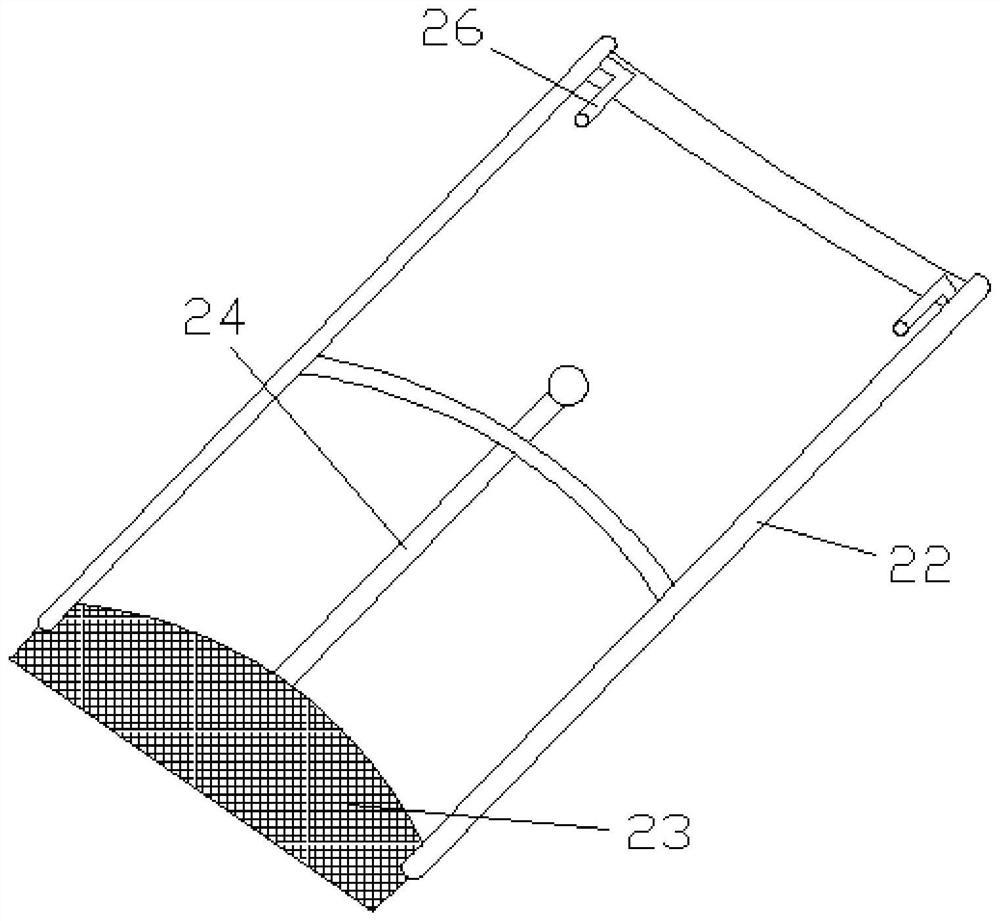

[0019] Embodiment one: Figure 1-Figure 2 A smokeless carbon cart is shown, which is mainly composed of: a car body 1 and a holding frame 2, and the holding frame 2 is arranged on the car body 1 and connected with the The car body is connected by a rotating shaft, and the transport barrel is placed through the holding frame. Most of the transport barrels are iron barrels. A barrel can hold about 100-200kg of smokeless carbon. The holding frame connected by the rotating shaft can effectively solve the difficulty of dumping after transportation. problem; the car body 1 is mainly composed of: a base plate 11, a vertical frame 14, an inclined frame 15 and a handrail 16, the lower end of the vertical frame 14 is connected with the right end of the base plate 11, and the inclined frame 15 One end of the armrest 16 is connected to the left end of the base plate 11, the other end of the inclined frame 15 is connected to the top of the vertical frame 14, one end of the handrail 16 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com