Automatic driving system of tower crane and tower crane

A technology for tower cranes and automatic driving, which is applied in the direction of cranes, traveling mechanisms, load suspension components, etc., and can solve problems such as easy fatigue, high psychological pressure, and reduced feasibility and reliability of automatic driving systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

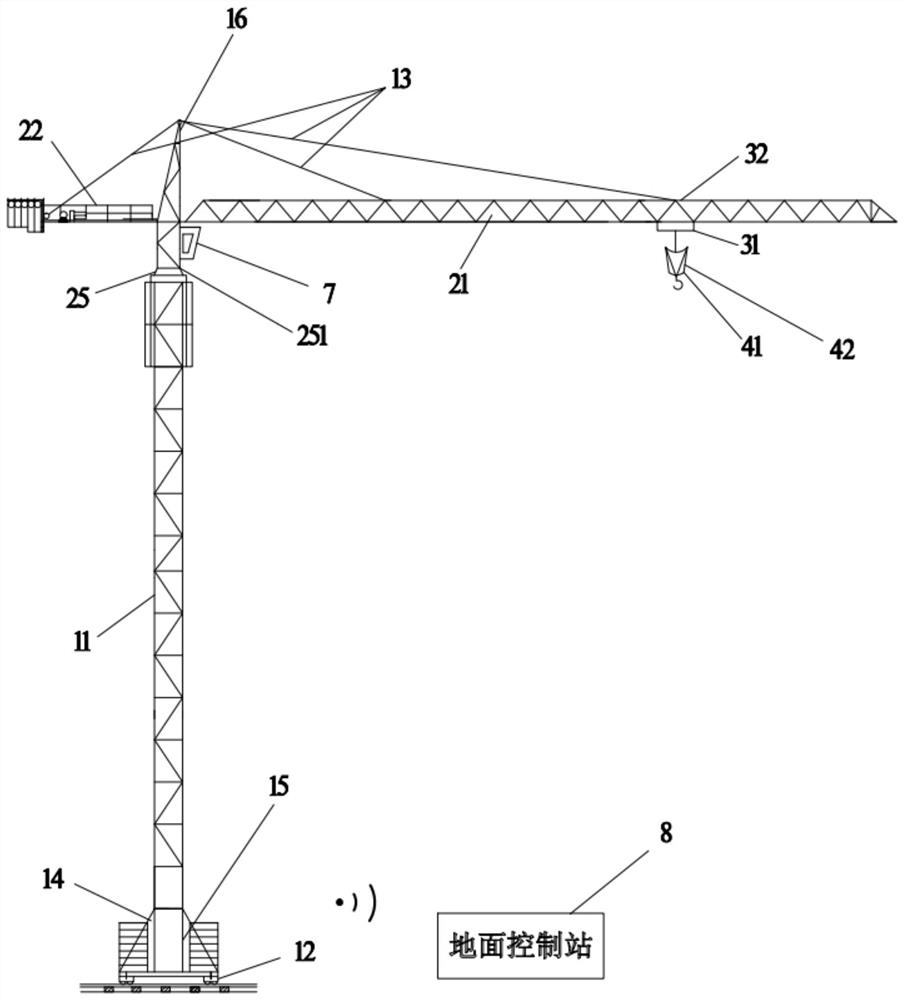

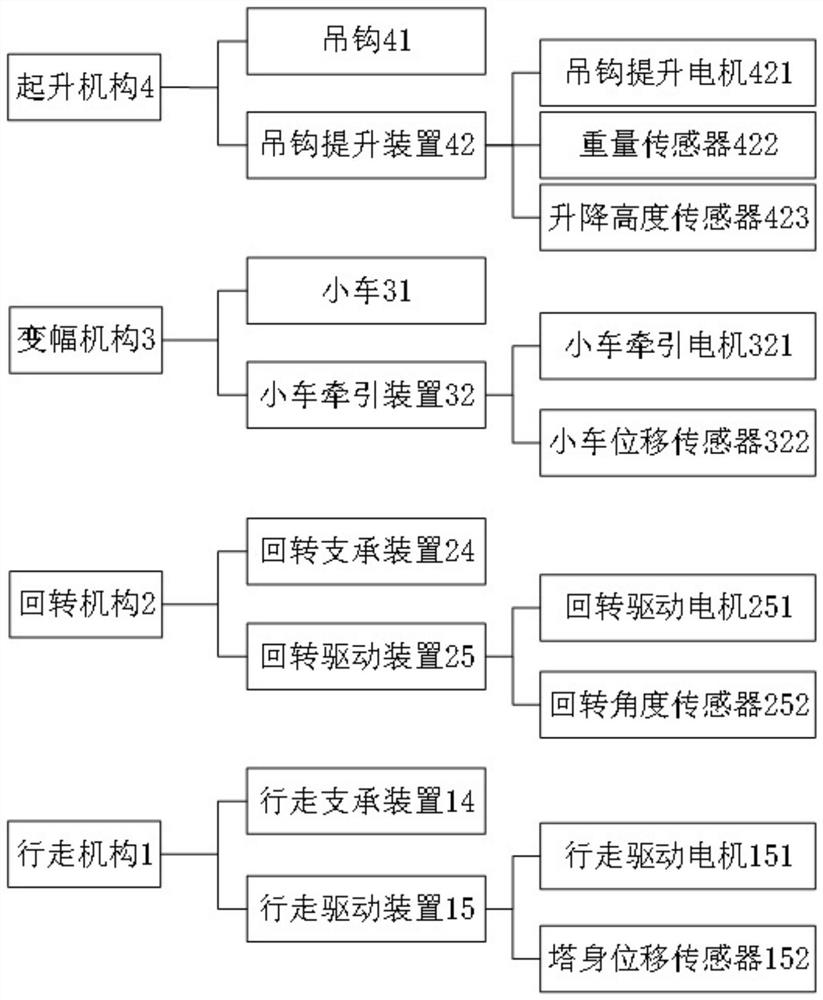

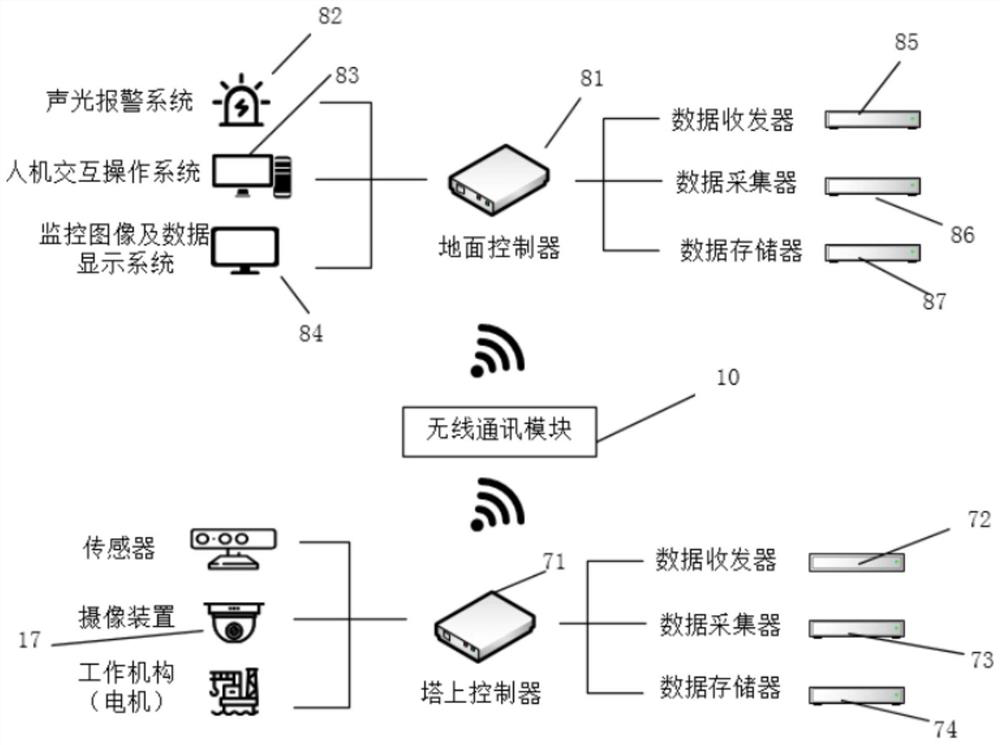

[0055] refer to Figure 1-5 As shown, Embodiment 1 adopts the following technical solutions: a tower crane automatic driving system, including a tower crane electromechanical mechanism, a cab 7 on the tower, and a ground control station 8, and the tower crane electromechanical mechanism includes a traveling mechanism 1 and a slewing mechanism 2 , luffing mechanism 3 and hoisting mechanism 4. The cab 7 on the tower is equipped with an unmanned automatic control system, including a controller 71 on the tower. The controller 71 on the tower can generate a motor control signal by using a series of sensor signals in the electromechanical mechanism of the tower crane and the set moving target. The control station 8 includes a ground controller 81, and the tower controller 71 of the cab 7 on the tower is connected to the ground controller 81 through a remote signal of the wireless communication module 10 to realize remote control of the tower crane. In this embodiment, the wireless c...

Embodiment 2

[0087] refer to Figure 6-7As shown, this embodiment, as a further limitation to Embodiment 1, adopts the following technical solutions: a tower crane automatic driving system, which also includes a remote control center 9, and the remote control center 9 is remotely connected through broadband, 5G and other network communication modules A plurality of on-tower controllers 71 and / or a plurality of ground controllers 81 . Further realize the collective remote control and management of tower cranes, which can realize the functions of driver's work sign-in, identity confirmation, remote tower crane driving, tower crane difficult problem consultation, tower crane operation status monitoring, etc., or solve the problem that the construction site does not meet the relevant conditions. Problem with ground station 8. Improve work efficiency while ensuring safety.

[0088] The remote control center 9 adopts the cloud control method, and the control modes and functions are more intell...

Embodiment 3

[0091] refer to Figure 8-13 As shown, this embodiment adopts the following technical solution as a further limitation to Embodiment 1 or Embodiment 2: a tower crane automatic driving system, the controller 71 on the tower controls the The action of each motor structure of the tower crane is controlled, such as starting and braking; the ground controller 81 is used to output to the tower controller 71 and record the start time and stop time of each motor structure.

[0092] The human-computer interaction operating system 83 has a built-in command editor (internal logic module, not shown in the figure), and the command editor is used to classify the sensor data collected by the ground controller 81, and record data of each sensor on the panel of the editor Generate command recording diagrams that change with driving time, including the variation diagrams of the boom rotation angle, the trolley displacement amplitude variation diagram, and the hook lifting height variation diagr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com