Rice husk fermentation process of special fertilizer for tobacco

A tobacco-specific fertilizer and fermentation process technology, applied in the field of fertilizer fermentation, can solve problems such as low efficiency and difficulty in mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

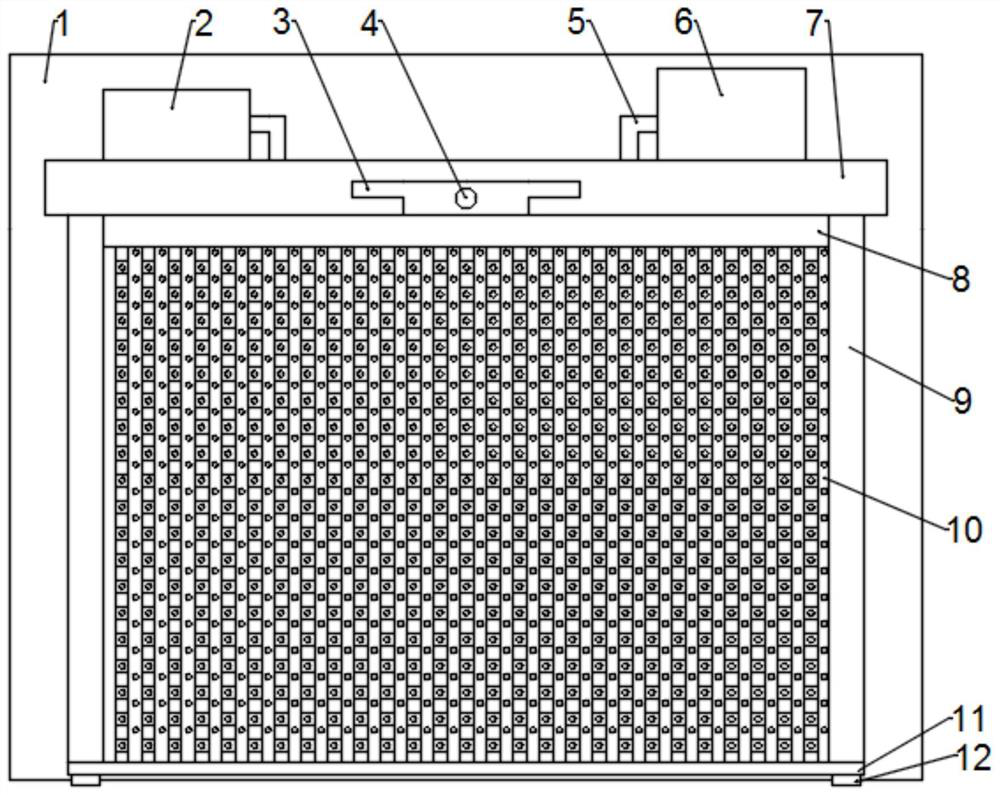

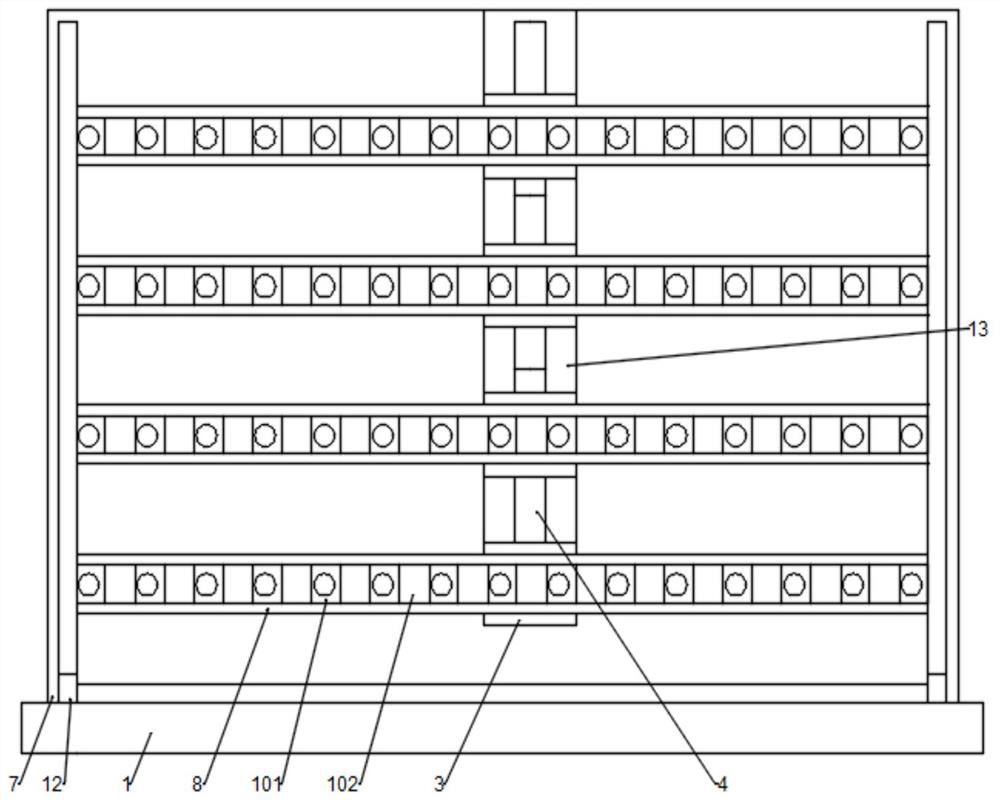

[0026] Embodiment 1 is basically as attached Figure 1~4 Shown: Fermentation process of fermented chaff special for tobacco, including the following steps:

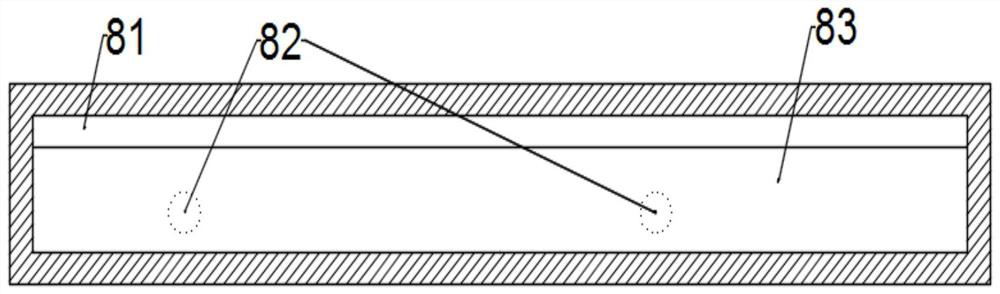

[0027] Step 1. Put the chaff into the fermentation equipment. The fermentation equipment includes a base 1, a water storage tank 2, a water pump, an oxygen generator 6 and a support plate 7 vertically and fixedly connected to the base 1. The water pump is arranged in the water storage tank 2 , the water pump and the oxygen generator 6 are connected with drainage tubes 5, and the support plate 7 is sequentially provided with a plurality of water supply boards 10 from top to bottom; The root guide tubes 101 are parallel to each other and the distance between adjacent guide tubes 101 is 0.8-1.5CM, and the multiple connecting pipes 102 are parallel to each other and the distance between adjacent connecting pipes 102 is 0.8-1.5CM; the connecting pipes 102 Perpendicular to the diversion pipe 101 and communicated with each othe...

Embodiment 2

[0033] Embodiment 2 is basically as attached Figure 5 As shown, the difference between it and Embodiment 1 is only that: the base 1 is provided with a spring support, the spring support is fixedly connected with a base plate, the support frame and the side plate 9 are all fixedly connected to the base plate, and the side plate 9 An exciter 14 is arranged on the outer wall; the drainage pipe 5 is a hose; during the fermentation of the chaff, the exciter 14 is started every 3 to 4 days, and the working time of the exciter 14 is 30 to 40 minutes.

Embodiment 3

[0034] The difference between embodiment 3 and embodiment 2 is that: the base 1 is provided with a controller, and the controller is electrically connected with the vibrator 14, temperature sensor, humidity sensor, oxygen generator 6 and water pump; the controller is used to control the vibrator 14. Turn on and off the temperature sensor, humidity sensor, oxygen generator 6 and water pump,

[0035] The controller is used to receive the chaff temperature information sent by the temperature sensor. When the temperature of the chaff is higher than 50°C, the controller controls the oxygen generator 6 to start, and the oxygen generated by the oxygen generator 6 acts on the chaff to cool down to 35°C~ 40°C;

[0036] The controller is used to receive the information sent by the humidity sensor. When the moisture content of the chaff is lower than 15%, the controller controls the water pump to start, and the water pump pumps water to supplement the moisture of the chaff until the mois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com