High-CTI value modified PBT material suitable for various colors and preparation method thereof

A modification and color technology, applied in the field of high CTI value modified PBT materials and its preparation, can solve the problems of reducing the tracking index of solid insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

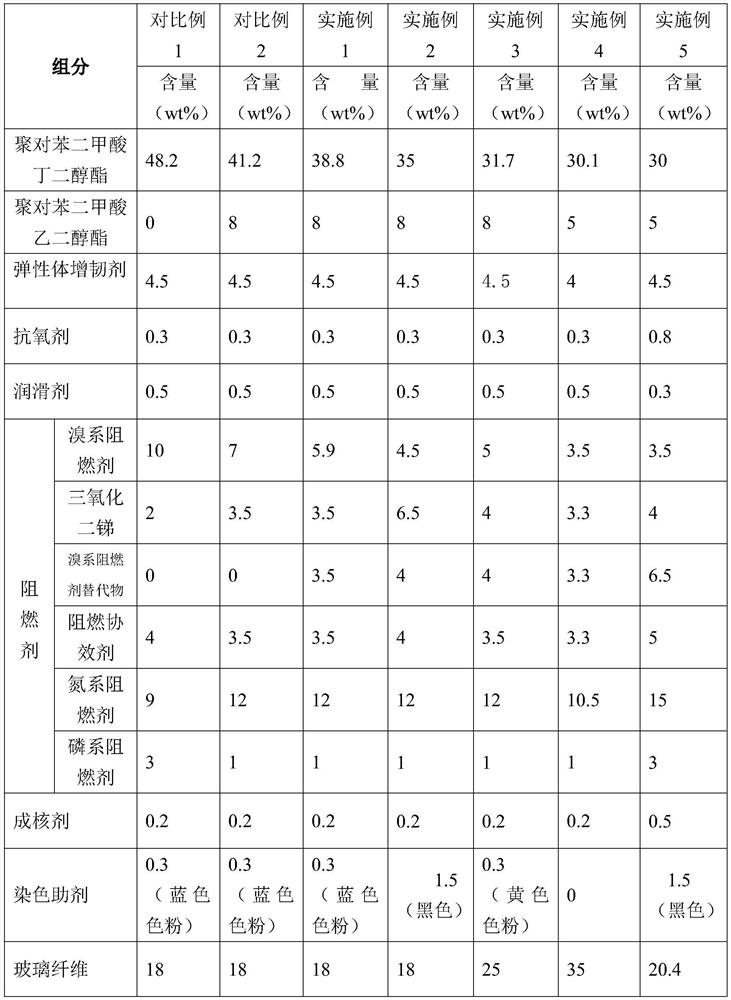

Examples

preparation example Construction

[0060] The invention discloses a method for preparing a modified PBT material with a high CTI value. The method for preparing a modified PBT material with a high CTI value is used to prepare the above-mentioned modified PBT material with a high CTI value, comprising the following steps:

[0061] (1) take each component according to proportioning;

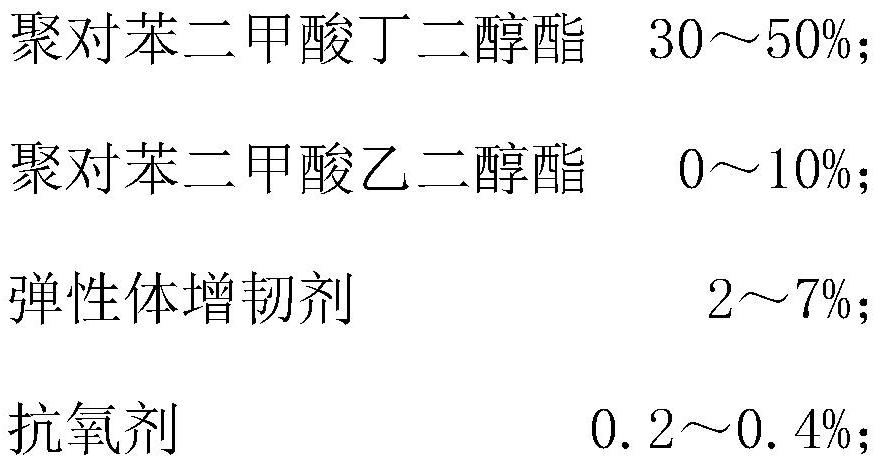

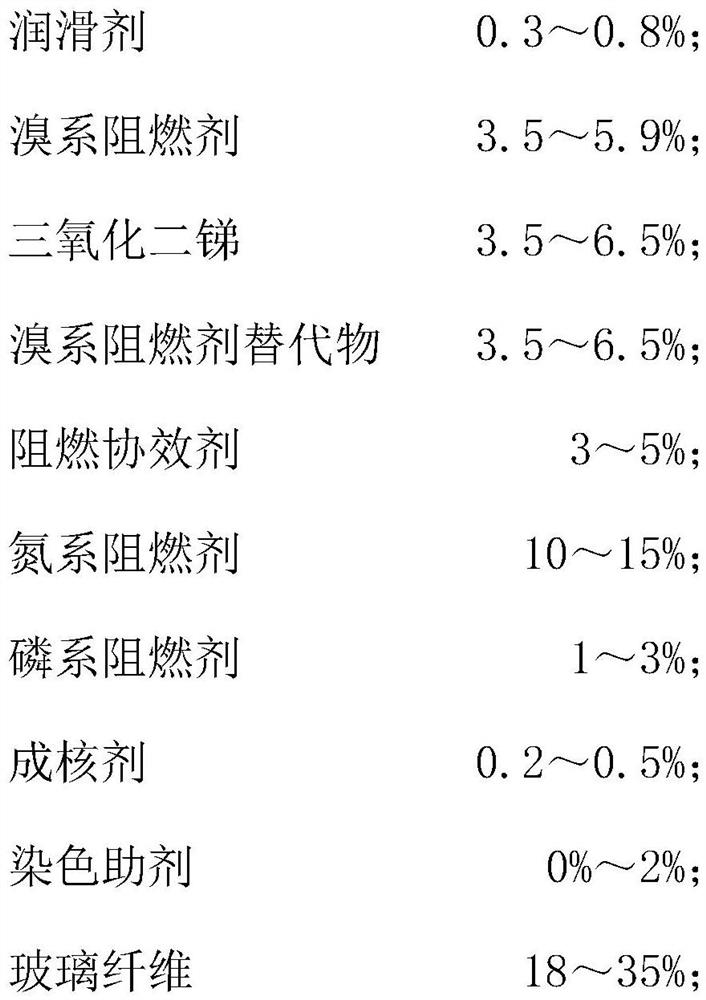

[0062] (2) Dry polybutylene terephthalate and polyethylene terephthalate so that the moisture content of polybutylene terephthalate and polyethylene terephthalate is less than 0.05% ; Add elastomer toughening agent, antioxidant, lubricant, brominated flame retardant, antimony trioxide, Brominated flame retardant substitutes, flame retardant synergists, nitrogen-based flame retardants, phosphorus-based flame retardants, nucleating agents and dyeing auxiliaries, and stir evenly;

[0063] (3) Put the mixed materials into the twin-screw extruder, and melt extrude. The melt extrusion temperature is 230-250°C, and the screw speed is 300-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com