High-CTI polyphenylene sulfide composite material and preparation method thereof

A polyphenylene sulfide and composite material technology, applied in the field of polymer materials, can solve problems such as insufficient CTI of polyphenylene sulfide composite materials, and achieve the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of preparation method of high CTI polyphenylene sulfide composite material, concrete steps are as follows:

[0037] (1) Preparation of raw materials;

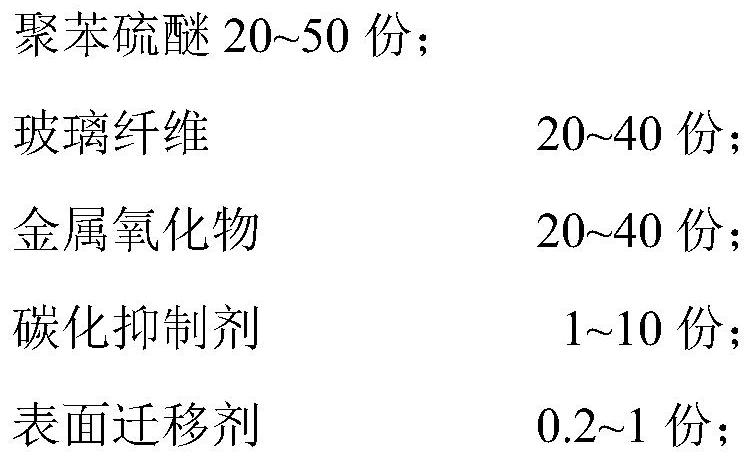

[0038] The parts by weight of each component are as follows:

[0039] 20 parts of polyphenylene sulfide;

[0040] 20 parts of glass fiber;

[0041] 24 parts of metal oxide;

[0042] 1 part of carbonization inhibitor;

[0043] 0.2 parts of surface migration agent;

[0044] The melt flow rate of polyphenylene sulfide at 316°C*5kg is 300g / 10min;

[0045] The glass fiber is a flat glass fiber with a silane-treated flat ratio of 2:1;

[0046] The metal oxide is zinc oxide with a particle size of 15-40 μm;

[0047] The carbonization inhibitor is triphenyl phosphate;

[0048] The surface migration agent is silicone;

[0049] (2) mixing polyphenylene sulfide, metal oxide, carbonization inhibitor and surface migration agent in a mixer and then discharging to obtain a mixture;

[0050] (3) The mixture is placed in...

Embodiment 2

[0053] A kind of preparation method of high CTI polyphenylene sulfide composite material, concrete steps are as follows:

[0054] (1) Preparation of raw materials;

[0055] The parts by weight of each component are as follows:

[0056] 25 parts of polyphenylene sulfide;

[0057] 23 parts of glass fiber;

[0058] 20 parts of metal oxide;

[0059] 3 parts of carbonization inhibitor;

[0060] 0.3 parts of surface migration agent;

[0061] The melt flow rate of polyphenylene sulfide at 316°C*5kg is 400g / 10min;

[0062] The glass fiber is a flat glass fiber with a silane-treated flat ratio of 3:1;

[0063] The metal oxide is zinc oxide with a particle size of 15-40 μm;

[0064] The carbonization inhibitor is triphenyl phosphate;

[0065] The surface migration agent is silicone;

[0066] (2) mixing polyphenylene sulfide, metal oxide, carbonization inhibitor and surface migration agent in a mixer and then discharging to obtain a mixture;

[0067] (3) The mixture is placed i...

Embodiment 3

[0070] A kind of preparation method of high CTI polyphenylene sulfide composite material, concrete steps are as follows:

[0071] (1) Preparation of raw materials;

[0072] The parts by weight of each component are as follows:

[0073] 30 parts of polyphenylene sulfide;

[0074] 30 parts of glass fiber;

[0075] 29 parts of metal oxide;

[0076] 4 parts of carbonization inhibitor;

[0077] 0.5 parts of surface migration agent;

[0078] The melt flow rate of polyphenylene sulfide at 316°C*5kg is 600g / 10min;

[0079] The glass fiber is a flat glass fiber with a silane-treated flat ratio of 4:1;

[0080] The metal oxide is alumina with a particle size of 15-40 μm;

[0081] The carbonization inhibitor is triphenyl phosphate;

[0082] The surface migration agent is silicone;

[0083] (2) mixing polyphenylene sulfide, metal oxide, carbonization inhibitor and surface migration agent in a mixer and then discharging to obtain a mixture;

[0084] (3) The mixture is placed in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com