Mold for growing large-size gallium oxide crystals by edge-defined film-fed growth and growth method

A gallium oxide, large-scale technology, applied in the field of crystal growth equipment, can solve problems such as poor crystal quality, achieve the effects of improving quality, reducing growth difficulties, and solving growth defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

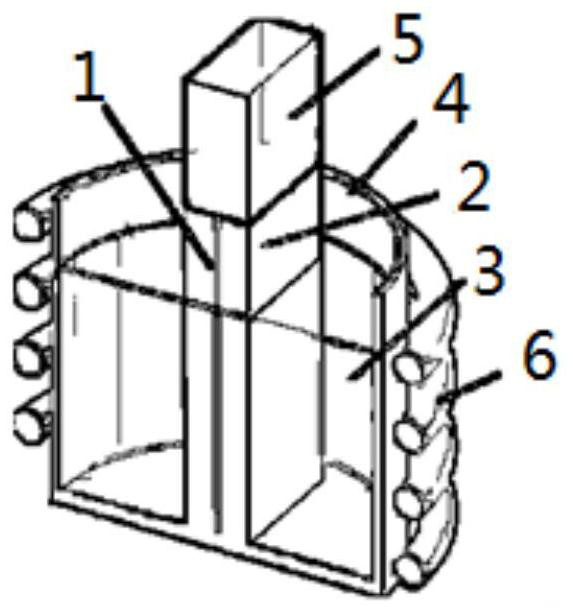

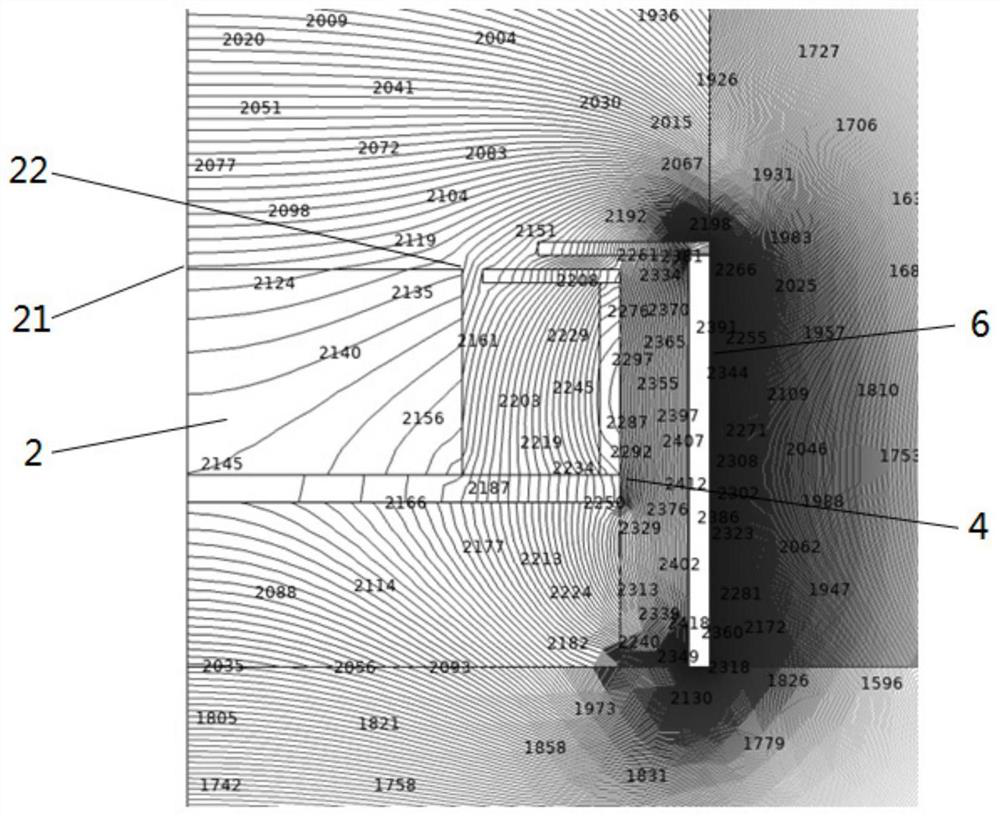

Method used

Image

Examples

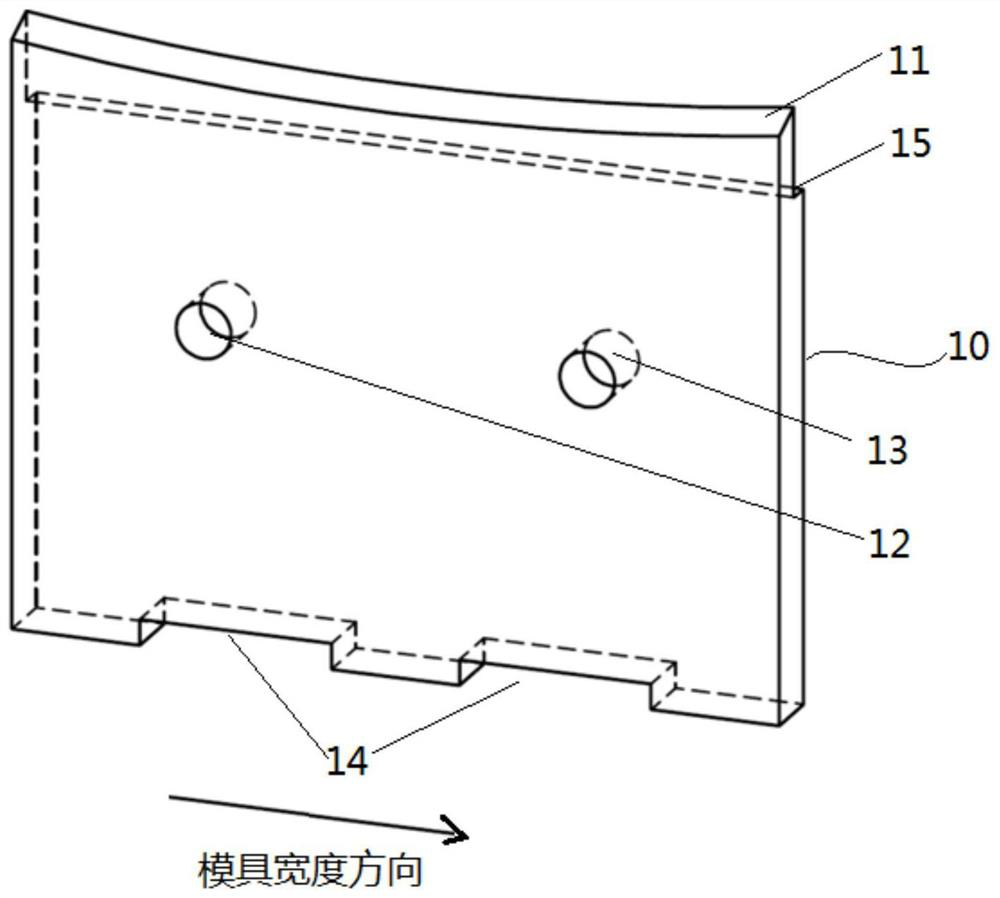

Embodiment 1

[0057] The furnace was charged with a structure basically the same as that of Comparative Example 1, the difference was that a mold with an arc-shaped top was used, and the lowest point of the center was about 1.5mm lower than the highest point. The shouldering process was relatively smooth throughout. After the shouldering reached 110mm, the center of the top of the mold remained in a stable crystalline state, and a complete gallium oxide single crystal with a width of 110mm was grown subsequently. The grown gallium oxide single crystal with a width of 110 mm was processed to obtain a 4-inch gallium oxide single crystal.

Embodiment 2

[0061] The furnace was loaded with a structure basically the same as that of Comparative Example 2, the difference was that the mold with an arc-shaped top was used, and the lowest point of the center was about 1.5mm lower than the highest point. In the seeding stage, the end of the seed crystal is in good contact with the top of the mold, and a thin layer of liquid film formed between the seed crystal and the top of the mold by the melt forms a perfect arc-shaped growth interface layer, and the temperature of the mold mouth is controlled to be constant and directly pulled , to obtain high-quality gallium oxide single crystals that are uniform, transparent, and free from visible defects. The grown gallium oxide single crystal with a width of 110 mm was processed to obtain a 4-inch gallium oxide single crystal.

[0062] To sum up, the present invention provides a mold and a growth method for growing large-sized gallium oxide crystals by the guided mode method. According to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com