Curtain production line and technological process thereof

A production line and curtain technology, applied in the direction of curtains, curtains, window decorations, etc., can solve the problems of skewed cutting, increased labor costs, waste of fabrics, etc., to reduce errors and resource waste, and reduce production labor costs. , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

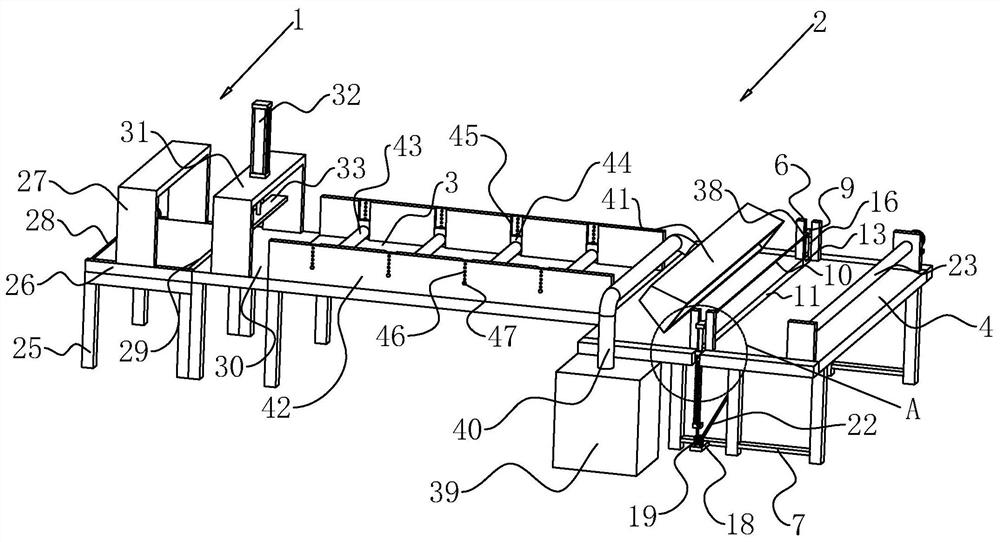

[0045] refer to figure 1 , a curtain production line, comprising a metal detection device 1 and a cloth cutting device 2, the metal detection device 1 includes a bracket 25 and a detection platform 26, a detection frame 27 is fixed above the detection platform 26, and the detection platform 26 is provided with a material inlet 28 and an outlet Feed port 29, curtain cloth is put into from the feed inlet 28 place of detection platform 26, conveys to discharge port 29 one end through detection platform 26, when curtain cloth passes through detection frame 27 below, is installed in the detection frame 27 and is used for detecting metal. The magnetoelectric sensor of object, detection frame 27 detects curtain cloth, detects whether there is metal object in curtain cloth.

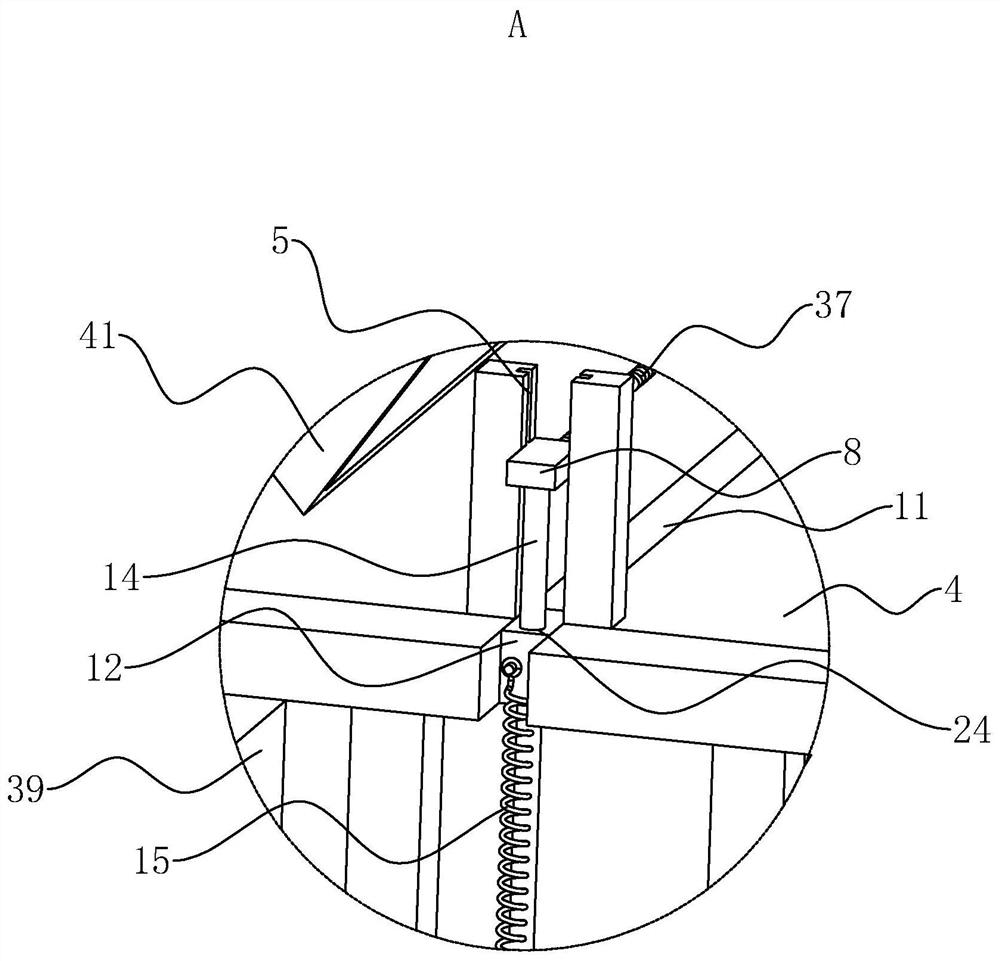

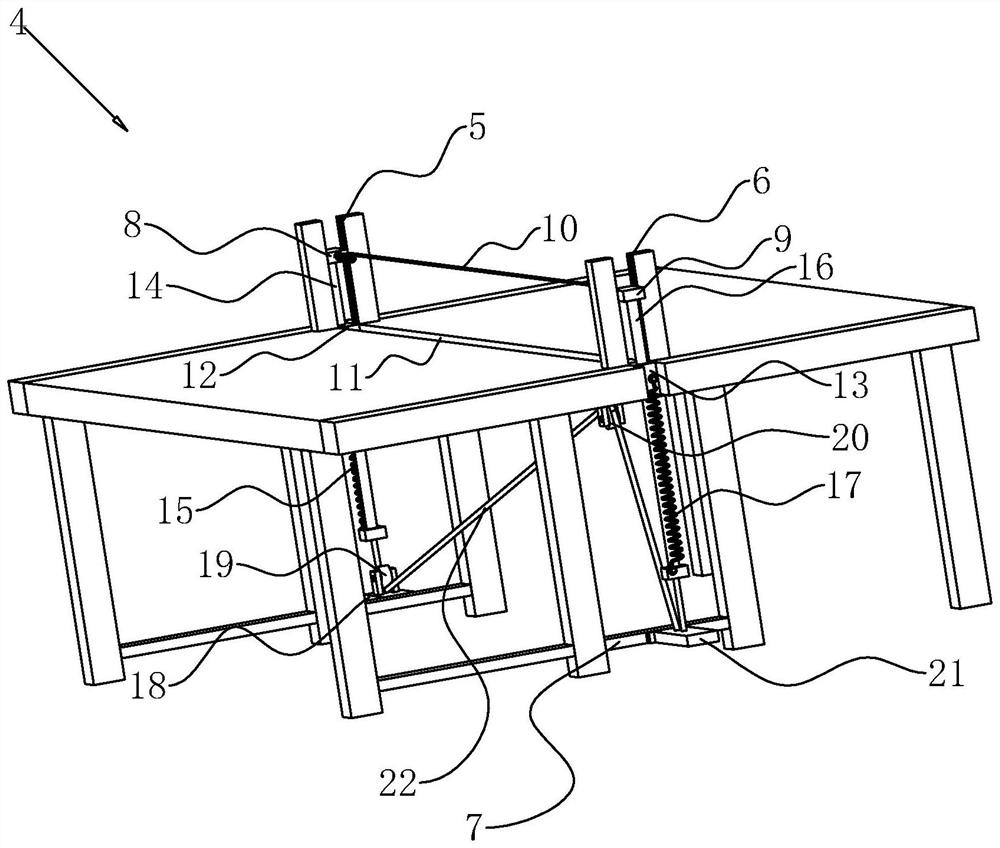

[0046] refer to figure 1 , the cloth cutting device 2 is provided with a cloth cutting table 3, and one end of the cloth cutting table 3 is provided with a material guide plate 4, the length of the material guid...

Embodiment 2

[0060] refer to figure 1 and Figure 4 The difference between this embodiment and Embodiment 1 is that the upper end of the material guide plate 4 is provided with a second support frame 34, and the upper end of the second support frame 34 is fixedly connected with a second cylinder 35, and the output end of the second cylinder 35 passes through A gantry frame 36 is fixedly connected through the second support frame 34, and two ends of the gantry frame 36 are fixedly connected with the first slider 8 and the second slider 9 respectively. When it is necessary to cut a large amount of curtain cloth, it is time-consuming and laborious to manually step on the pedal 21; The ends are respectively fixed with the first slider 8 and the second slider 9, so that the first slider 8 and the second slider 9 move down synchronously, and then the thermal conduction wire 10 performs cloth cutting processing on the curtain cloth, which is suitable for mass production Cutting the curtain clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com